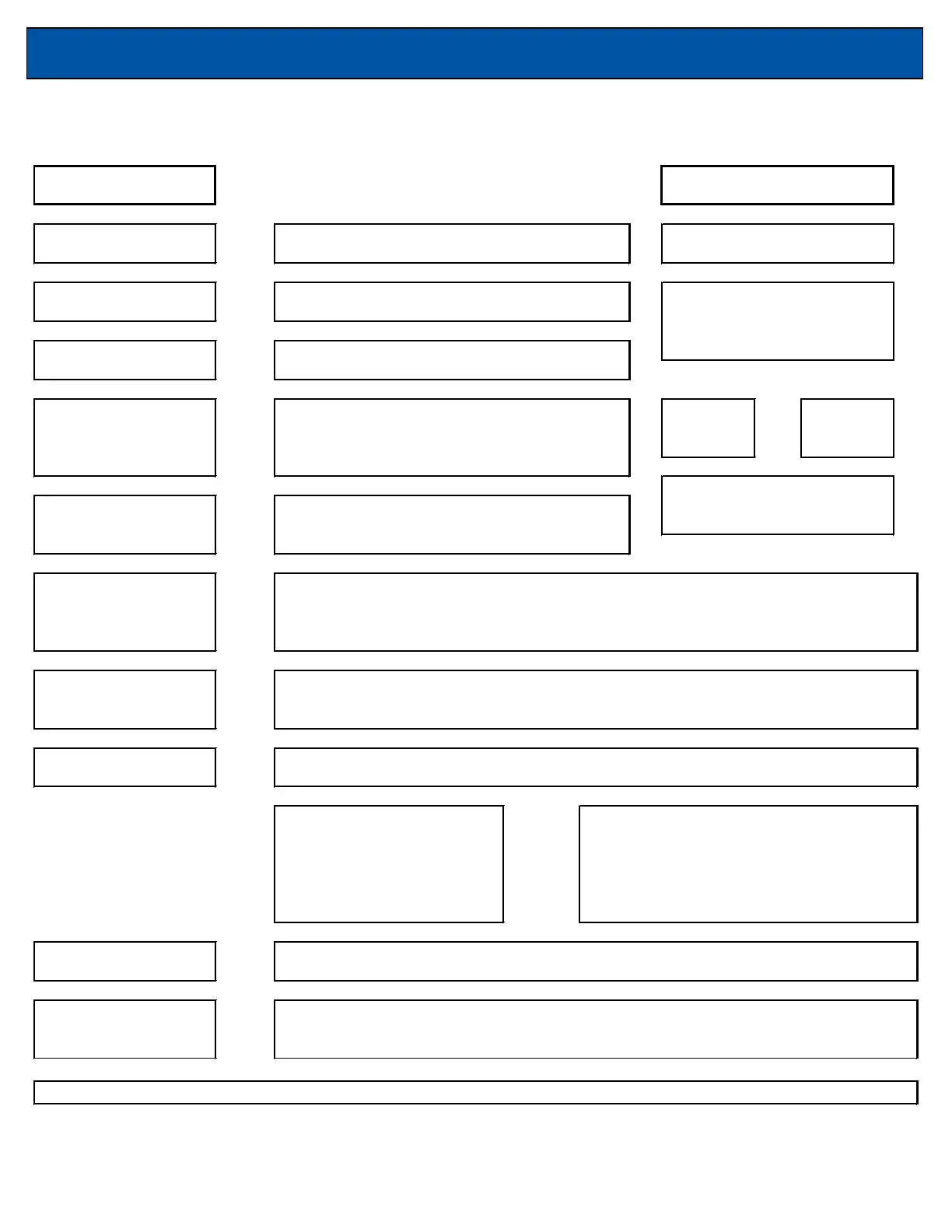

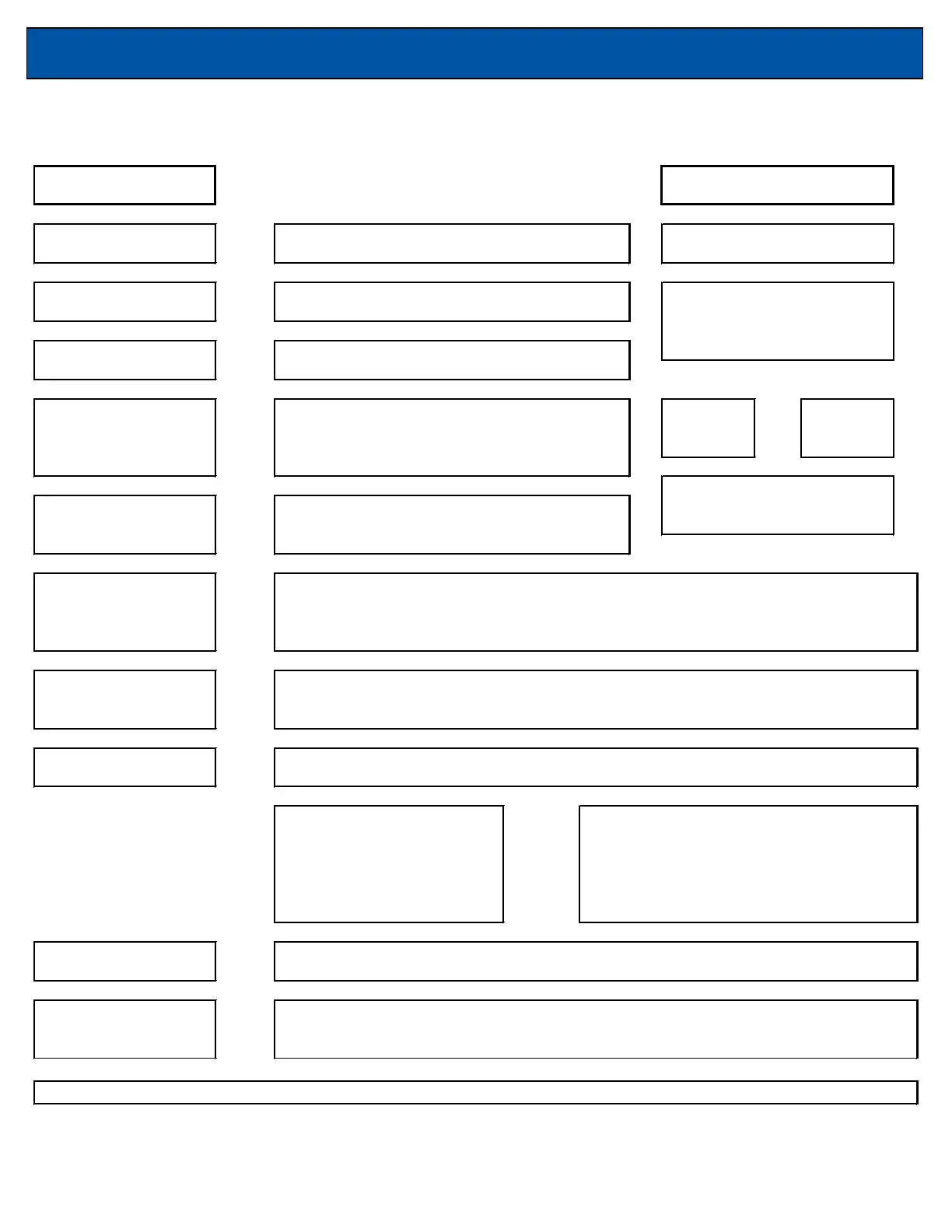

TROUBLESHOOTING ENDS: REPEAT PROCEDURE UNTIL TROUBLE FREE OPERATION IS OBTAINED

TURN THERMOSTAT UP TO A HIGHER TEMPERATURE

ADD FUEL. MINIMUM LEVEL MUST BE ABOVE PICK UP TUBE

IN TANK

TURN BURNER SWITCH TO "ON" POSITION

DOES THE BURNER MOTOR

TURN?

WITH THE BURNER SWITCH ON AND THE THERMOSTAT TURNED UP, CHECK FOR 12VDC AT THE SMALL

TERMINAL ON THE BURNER (CUBE) RELAY WHEN THE TRIGGER IS PULLED. DO YOU GET VOLTAGE?

IS THERE FUEL IN THE TANK?

CHECK OUT UNIT! REPLACE ANY

DAMAGED HOSES, O-RINGS, TRIGGER

GUN

JUMP ACROSS THE TWO BIG RELAY

TERMINALS TOGETHER (CAUTION-

ONLY FOR 1-2 SECONDS). IF THE

BURNER MOTOR STARTS REPLACE

THE CUBE RELAY. IF NOT, REPLACE

THE BURNER MOTOR.

ADJUST FUEL PRESSURE TO SPEC. CHECK / REPLACE FUEL FILTER & REPAIR ANY AIR LEAKS. IF PROPER

PRESSURE CANNOT BE OBTAINED, REPLACE FUEL PUMP.

IS THE FUEL PRESSURE 140

PSI (+ - 10 PSI)?

LOOSEN COPPER FUEL LINE.

PULL TRIGGER GUN. DOES

FUEL DISCHARGE FROM LINE?

PULL TRIGGER GUN. IF NO FUEL DISCHARGES FROM LINE CHECK ELECTRICAL CONNECTION. CHECK

VOLTAGE AT SOLENOID VALVE. IF VOLTAGE READING IS 12VDC OR HIGHER REPLACE SOLENOID VALVE. IF NO

VOLTAGE CHECK FLOW / PRESSURE SWITCH FOR CONTINUITY.

(Also applicable to SC Series with 12V DC burners)

IS THE SPRAY TIP INSTALLED?

IS THE TRIGGER BEING

PULLED AND PRESSURIZED

WATER SPRAYING?

REPLACE THE

PRESSURE OR

FLOW SWITCH

DISCONNECT THE WIRES FROM ONE

SMALL TERMINAL ON THE BURNER

RELAY. DOES THE BURNER CONTINUE

TO FIRE?

INSTALL SPRAY TIP, BURNER REQUIRES 1000 PSI TO

OPERATE, IF UNIT IS EQUIPPED W/DUAL LANCE WAND,

CLOSE VALVE TO INCREASE PRESSURE, VERIFY PROPER

NOZZLE SIZE.

TRIGGER MUST BE PULLED TO OPERATE PRESSURE/FLOW

SWITCH

IS THE SWITCH ENGAGED TO

"ON" POSITION?

!! CAUTION!! TURN UNIT OFF

IMMEDIATELY AND REPAIR

IS THE THERMOSTAT TURNED

UP?

IS THERE FUEL VAPOR

COMING OUT OF THE

EXHAUST?

CHECK THE TRANSFORMER FOR SPARK.

!!CAUTION HIGH VOLTAGE!! CHECK ELECTRODE ADJUSTMENT AND

AIR BAND ADJUSTMENT (IMPORTANT!-SEE BURNER SPEC SHEET FOR SETTING ELECTRODE GAP). CHECK

ELECTRODES FOR CRACKS. CHECK LIGHT SENSING CAD CELL CONTROL CIRCUIT. REPLACE FUEL NOZZLE.

RESET THE BREAKER AND/OR REPLACE THE FUSE. LOOK FOR SHORT/OVERLOAD FAILURE AND REPAIR.

CHECK ENGINE OUTPUT VOLTAGE, MUST BE 12V DC OR HIGHER & LOAD TEST THE BATTERY. CHECK ENGINE

RPM: 3200 RPM FOR BELT DRIVE, 3400 RPM FOR DIRECT DRIVE. REPAIR CHARGING SYSTEM CIRCUIT AND/OR

REPLACE BATTERY IF NEEDED. LOW VOLTAGE WILL AFFECT BURNER PERFORMANCE.

IS THE BREAKER ON THE

PANEL TRIPPED OR IS THE

INLINE FUSE BLOWN?

CHECK HEAT SWITCH/THERMOSTAT FOR CONTINUITY

(THERMOSTAT MUST BE ADJUSTED TO HIGHEST SETTING

BEFORE TESTING-REPLACE IF NO CONTINUITY). CHECK

PRESSURE SWITCH FOR CONTINUITY WHEN MACHINE IS

RUNNING AND WITH TRIGGER PULLED - REPLACE IF NO

CONTINUITY.

Loading...

Loading...