3.

Clean valve guides.

CAUTION

To prevent possible gouging of the cylinder head

surfaces, use care when removing gasket mate-

rial.

4.

Remove all gasket material from surfaces of

cylinder head.

5.

Inspect cylinder head for following defects:

• Damage to gasket surfaces

• Damage to threaded bolt holes

• Burnt or eroded areas in combustion

chamber

• Cracks in exhaust ports and combustion

chambers

• External cracks in water chamber

• Restrictions in intake or exhaust pas-

sages

• Restrictions in cooling system passages

• Rusted, damaged, or leaking core plugs

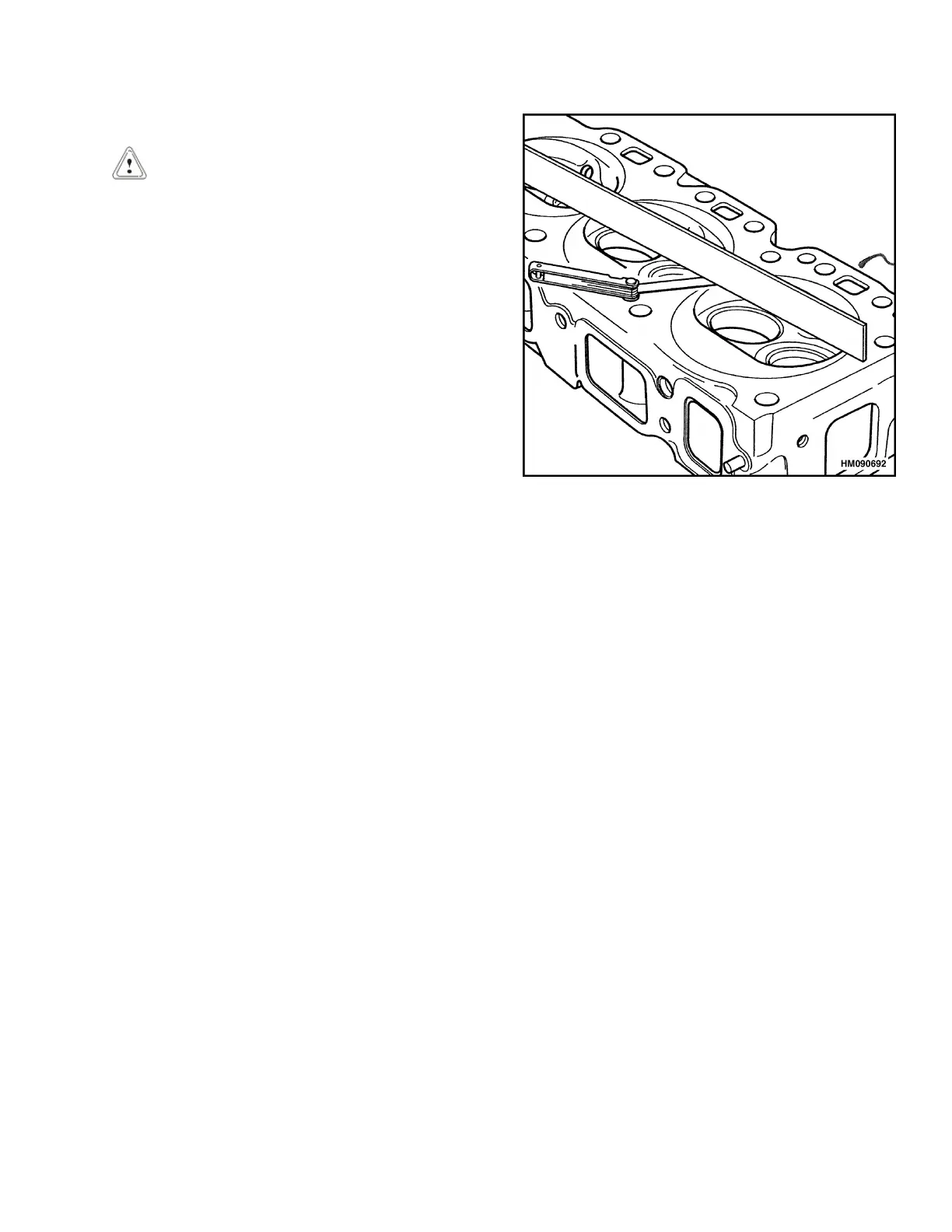

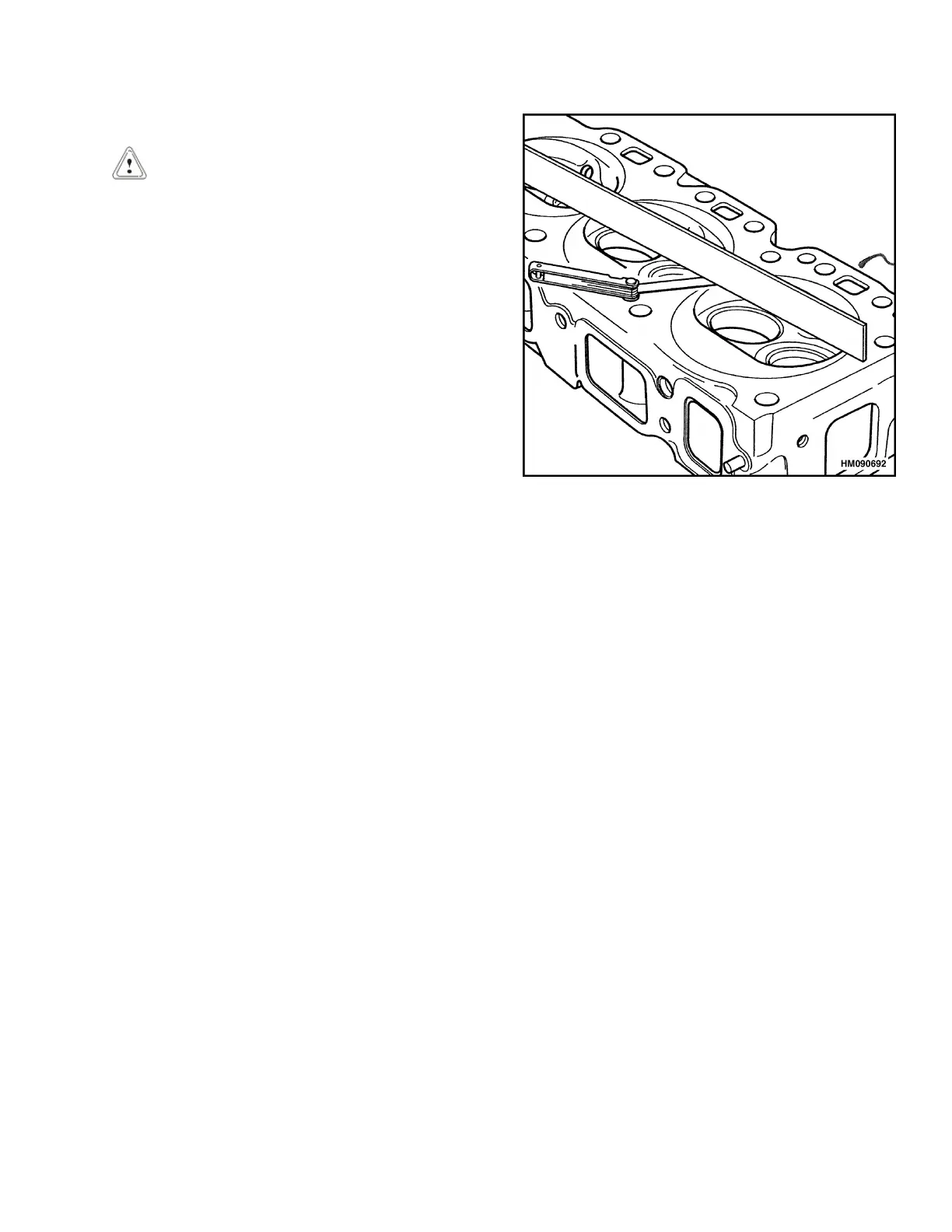

6.

Measure cylinder head for warpage with a

straight edge and feeler gauge. See Figure 6.

• A cylinder head block deck with warpage

in excess of 0.10 mm (0.004 in.) within a

152.4 mm (6.0 in.) area must be repaired

or replaced.

• A cylinder head exhaust manifold mount-

ing surface with a warpage in excess of

0.05 mm (0.002 in.) within a

152.4 mm (6.0 in.) area must be repaired

or replaced.

• A cylinder head intake manifold mount-

ing surface with a warpage in excess of

0.10 mm (0.004 in.) within a

152.4 mm (6.0 in.) area must be repaired

or replaced.

Figure 6. Cylinder Head Warpage Inspection

7.

Inspect valves for:

• Burnt or damaged areas

• Undersized margin

• Bent stem

• Scoring or other damage to stem

• Worn key groove

• Worn stem tip

See Figure 7.

0600 SRM 1251 Cylinder Head Repair

5

Loading...

Loading...