NOTE: ONCE THE VALVE ROCKER ARM ASSEM-

BLIES ARE INSTALLED AND PROPERLY TOR-

QUED, NO ADDITIONAL VALVE LASH ADJUST-

MENT IS REQUIRED.

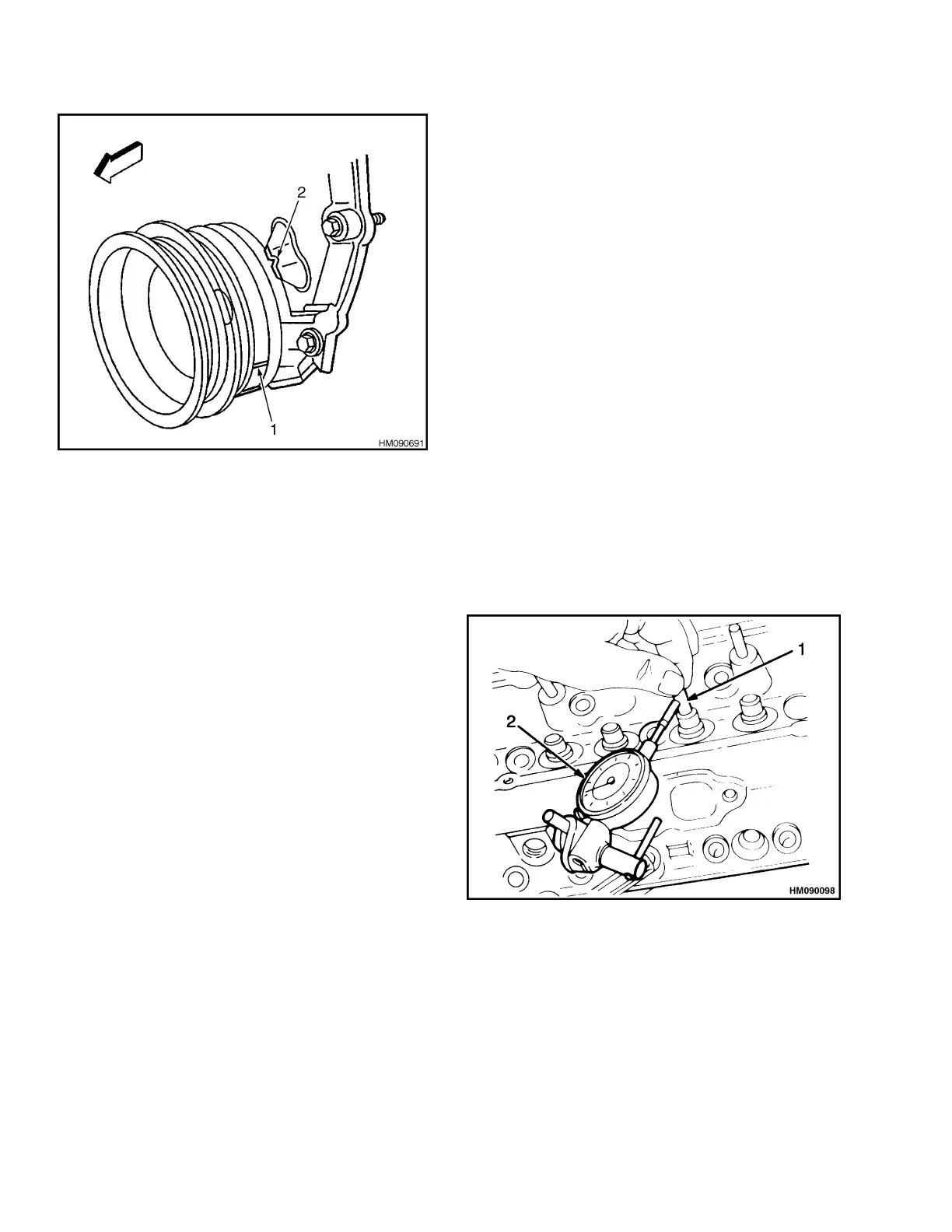

1. CRANKSHAFT BALANCER ALIGNMENT MARK

2. ENGINE FRONT COVER ALIGNMENT TAB

Figure 13. Rotate Crankshaft Balancer

5.

Tighten valve rocker arm bolts to 30 N•m (22

lbf ft). See Figure 19. Repeat for other side.

6.

Use new gasket and install rocker covers. In-

stall new grommets on capscrews and install

capscrews into rocker covers. Tighten cap-

screws to 12 N•m (107 lbf in). See Figure 22.

Repeat for other side.

7.

Install air inlet hose on PCV valve. Tighten

clamp.

8.

Install each spark plug wire shield and spark

plugs.

9.

Install spark plug wires to their appropriate

spark plugs.

VALVE GUIDES AND SEATS, REPAIRS

Measure clearance between valve stem and guide

as follows:

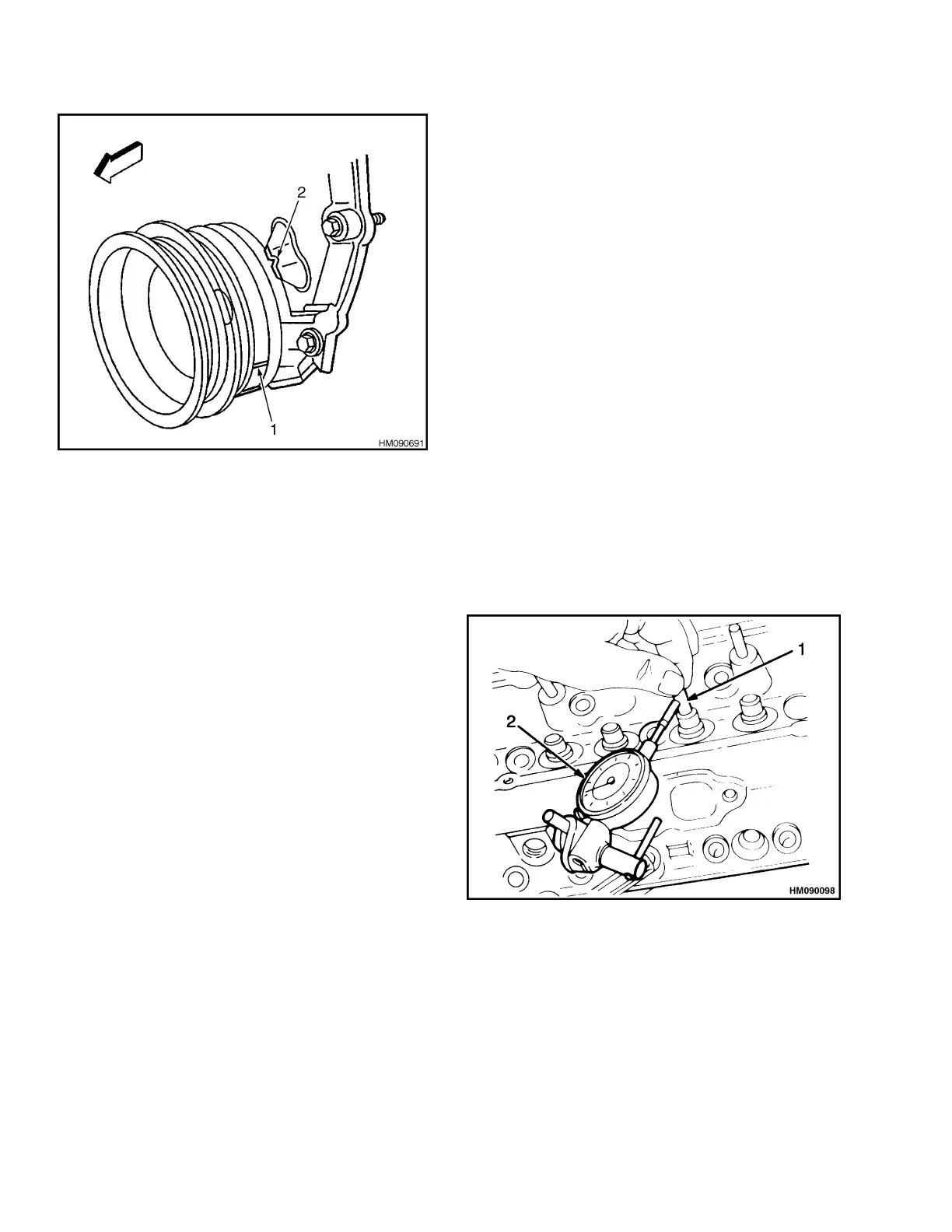

1.

Clamp a dial indicator on exhaust port side

of the cylinder head. See Figure 14.

2.

Position dial indicator so that movement of

valve stem from side to side, crosswise to cyl-

inder head, will cause a direct movement of

dial indicator stem.

The dial indicator stem must contact side of

valve stem just above valve guide.

3.

Lower valve head about 1.6 mm (0.063 in.)

below valve seat.

4.

Using light pressure, move valve stem from

side to side in order to obtain valve stem-to-

guide clearance reading.

See Engine Specifications for maximum clearances.

If clearance is more than maximum amount, over-

size valves or new valve guides must be installed.

Use a reamer of correct size when installing new

valve guides. Use normal service procedures when

grinding valve seats. See Engine Specifications for

dimensions.

1. VALVE STEM

2. DIAL INDICATOR

Figure 14. Valve Steam Clearance

Cylinder Head Repair 0600 SRM 1251

10

Loading...

Loading...