11

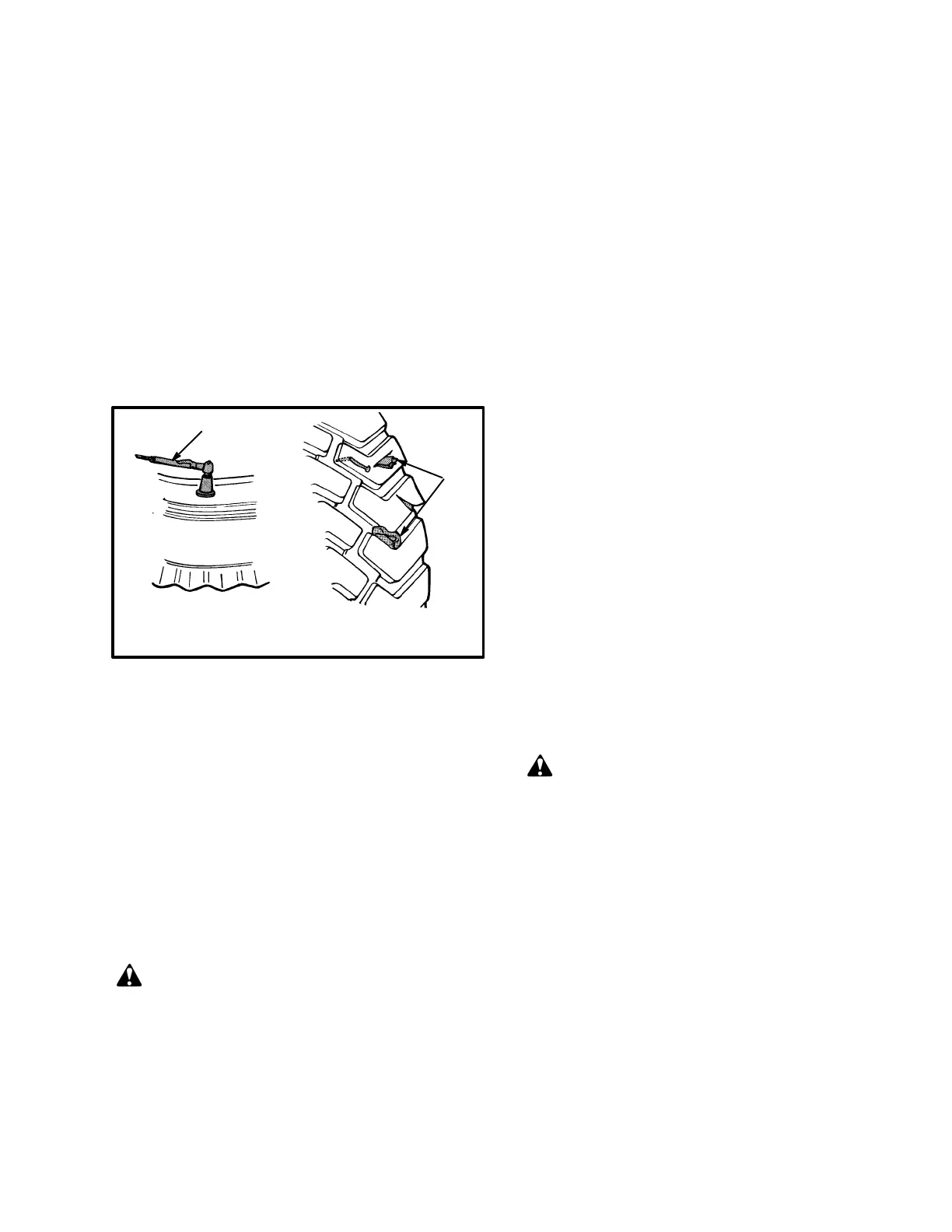

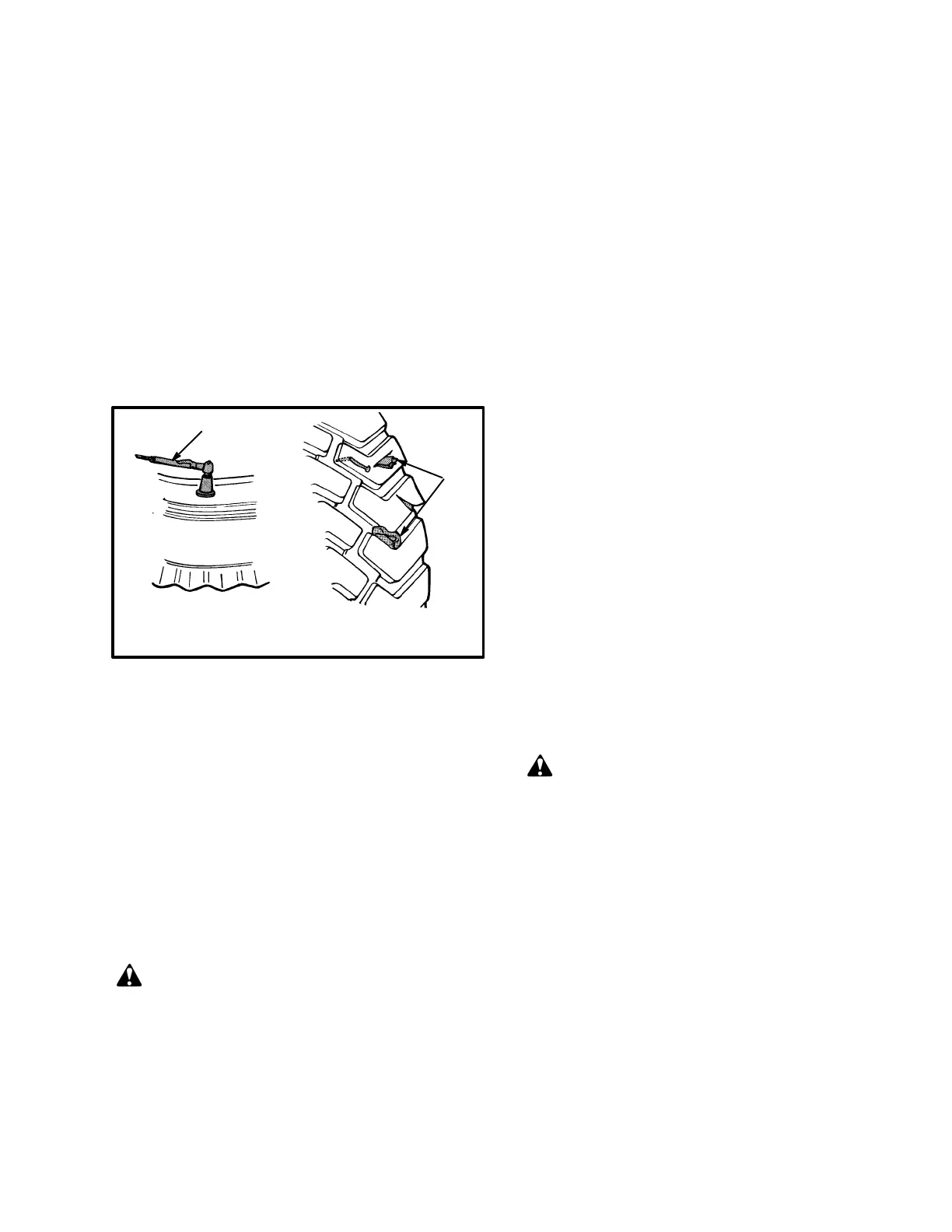

When air is added to the tires, use a remote air chuck.

The person adding air must stand away and to the

side and not in front of the tire.

Keep the tires at the correct air pressure. (See the Name-

plate.) Check the air pressure with a gauge when the

tires are cold. If it is necessary to add air to a tire that is

warm, check one of the other tires on the same axle and

add air to the tire that has low pressure so that the air

pressures are equal. The air pressure of the warm tires

must always be equal to or greater than the specification

for air pressure for cold tires.

1. CHECK THE TIRE PRESSURE

2. CHECK FOR DAMAGE

9447

FIGURE 10. CHECK THE TIRES

1

2

Check the tires for damage. Check the tread and remove

any objects that will cause damage. Check for bent or

damaged rims. Check for loose or missing parts. Re-

move any wire, straps or other material wrapped around

the axle.

Make sure the drive wheel nuts are tight. Tighten the

wheel nuts in a cross pattern to the correct torque value

shown in the MAINTENANCE SCHEDULE.

CAUTION

When the drive wheels have been installed check all

wheel nuts after 2 to 5 hours of operation. Tighten

the nuts in a cross pattern to the correct torque value

shown in the MAINTENANCE SCHEDULE. When

the nuts stay tight for eight hours, the interval for

checking the torque can be extended to 350 hours.

Forks

The identification of a fork is how the fork is connected

to the carriage. The H3.50–5.00XL (H70–110XL) se-

ries of lift trucks can have either a hook fork or a pin

fork. The H6.00–7.00XL (H135–155XL) series of lift

trucks normally have a pin fork. See FIGURE 13.

Forks, Adjustment

Hook forks are connected to the carriage by hooks and

lock pins. See FIGURE 12. These lock pins are installed

through the top fork hooks and fit into slots in the top

carriage bar. Adjust the forks as far apart as possible for

maximum support of the load. Hook forks will slide

along the carriage bars to adjust for the load to be lifted.

Raise the lock pin in each fork to slide the fork on the

carriage bar. Make sure the lock pin is engaged in the

carriage bar to lock the fork in position after the width

adjustment is made.

Pin forks are fastened to the carriage with large fork

pins. A lock pin for each fork fits into the top carriage

bar and a slot in the fork. These lock pins hold the fork in

position. See FIGURE 13. Adjust the forks as far apart

as possible for maximum support of the load. Make sure

the lock pin is engaged in the carriage bar and the fork.

The fork must be locked into position after the adjust-

ment is made.

Forks, Removal And Installation

WARNING

Do not try to move a fork without a lifting device.

Each fork for these lift trucks can weigh (66 kg to 183

kg [145 to 402 lb] for a hook fork) and (128 to 226 kg

[281 to 498 lb] for a pin fork).

A fork can be removed from the carriage for replace-

ment of the fork or other maintenance.

Hook Fork (Removal). Slide a hook fork to the fork re-

moval notch on the carriage. See FIGURE 12. Lower

the fork onto blocks so that the bottom hook of the fork

moves through the fork removal notch. See

FIGURE 11. Lower the carriage further so that the top

hook of the fork is disengaged from the top carriage bar.

Move the carriage away from the fork, or use a lifting

device to move the fork away from the carriage.

Loading...

Loading...