12

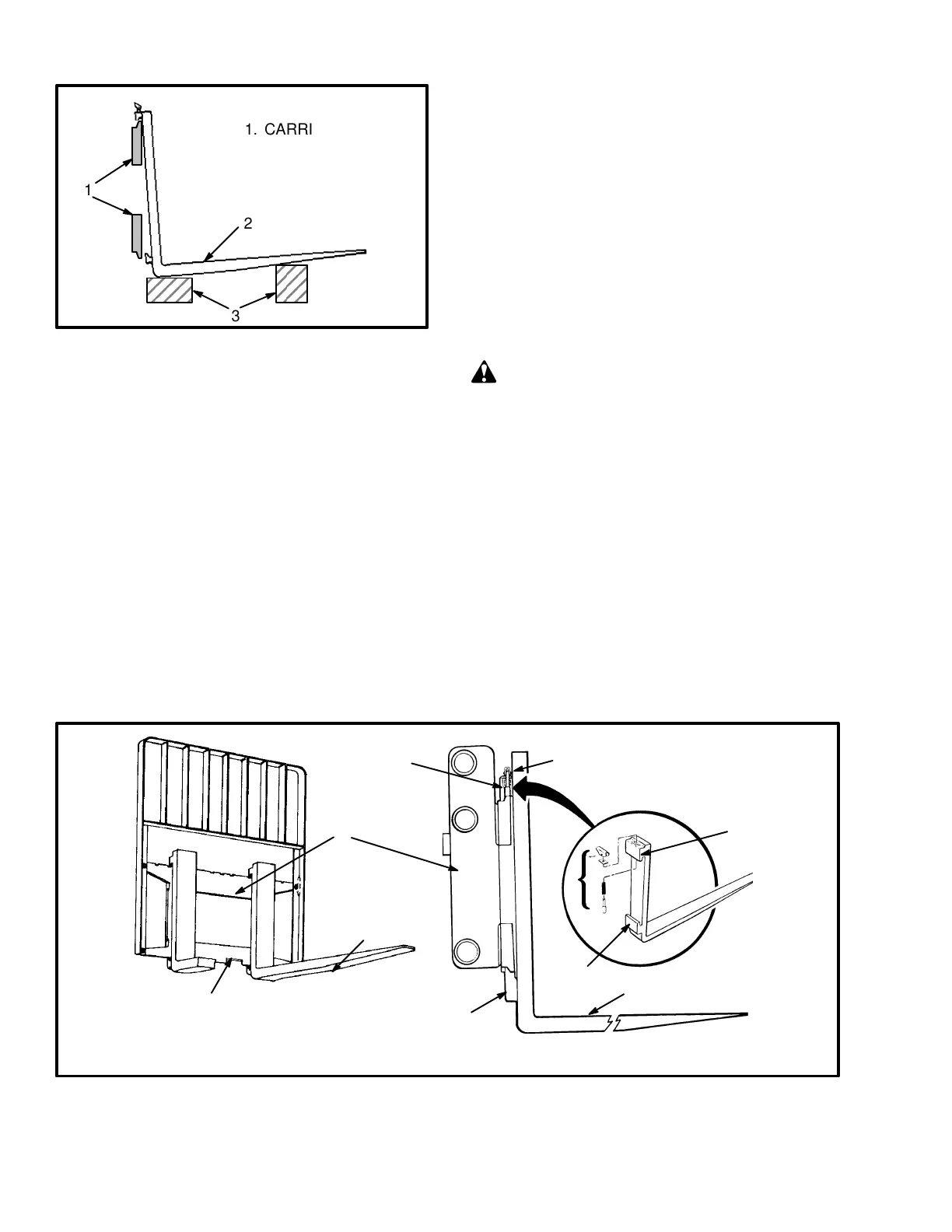

FIGURE 11. REMOVE A HOOK FORK

1

3

2

1. CARRIAGE BARS

2. HOOK FORK

3. BLOCKS

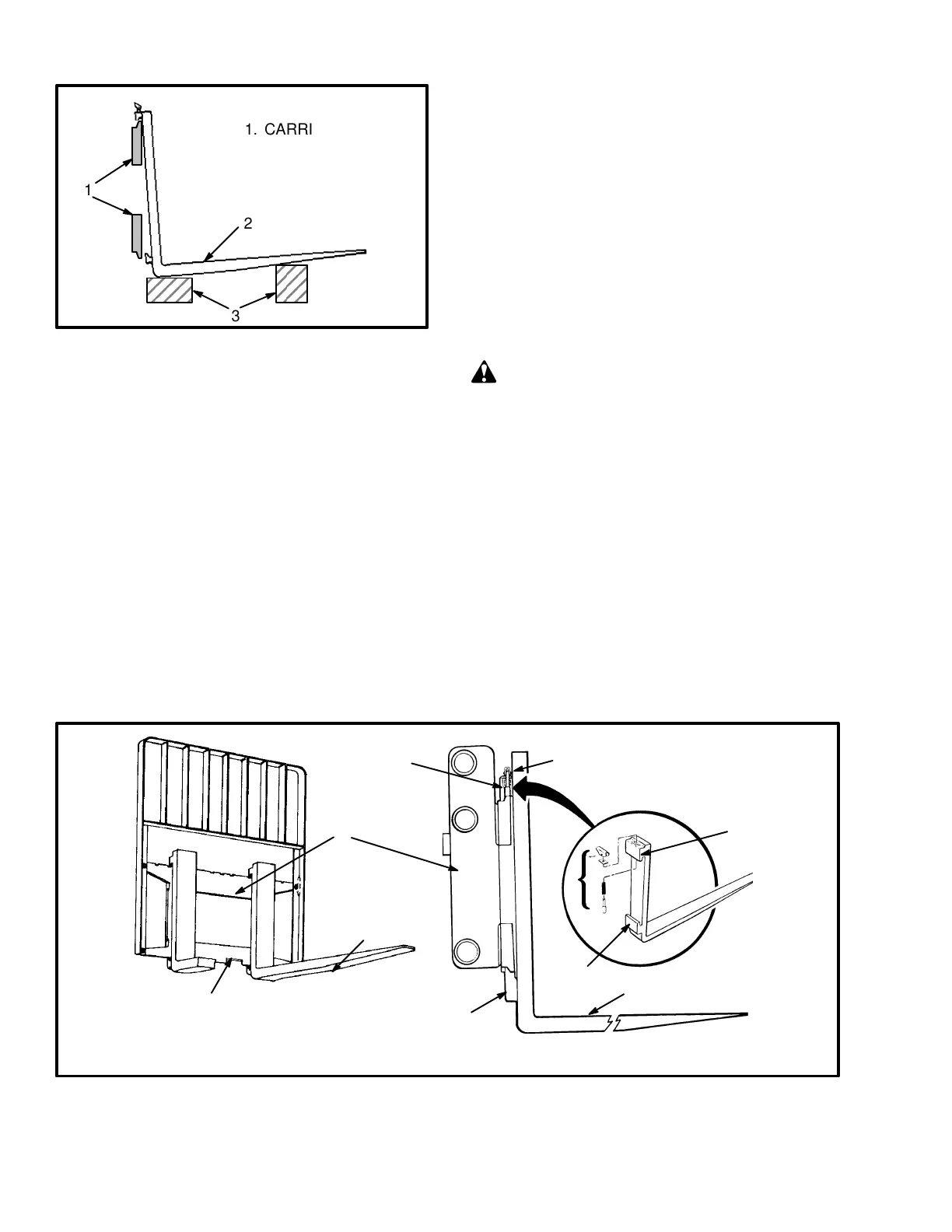

Hook Fork (Installation). Move the fork and carriage

so that the top hook on the fork can engage the upper car-

riage bar. Raise the carriage to move the lower hook

through the fork removal notch. Slide the fork on the

carriage so that both upper and lower hooks engage the

carriage. Engage the lock pin with a notch in the upper

carriage bar.

Pin Fork (Removal). Lower the carriage and put blocks

under a pin fork. When the weight of the forks have been

removed from the fork pin, remove the load backrest ex-

tension. The load backrest extension holds the fork pin

in the carriage. Slide the fork pin from its mount in the

carriage and through the eye of the fork. See

FIGURE 13. Use a lifting device to lift the fork away

from the carriage.

Pin Fork (Installation). Install the fork pin in the car-

riage. Align the eyes of the forks so that the forks will be

installed on the fork pin. When the fork pin is installed in

the carriage so that it holds the forks, install the load

backrest extension. Engage the fork with the lock pin.

Inspection Of Forks, Mast, and Lift Chains

(See FIGURE 14. and FIGURE 15.)

WARNING

Never work under a raised carriage or forks. Lower

the carriage or use blocks and chains on the mast

weldments and carriage so that they can not move.

Make sure the moving parts are attached to a part

that does not move.

Do not try to correct the alignment of the fork tips by

bending the forks or adding shims. Replace dam-

aged forks.

Never repair damaged forks by heating or welding.

Forks are made of special steel using special proce-

dures. Replace damaged forks.

1. FORK REMOVAL NOTCH

2. FORK

3. HOOK

1545

2

5

1

4

3

2

3

3

3

4

4. LOCK PIN ASSEMBLY

5. CARRIAGE

FIGURE 12. HOOK FORK

Loading...

Loading...