13

12565

1

2

3

4

5

5

1

1

2

2

3

3

4

2

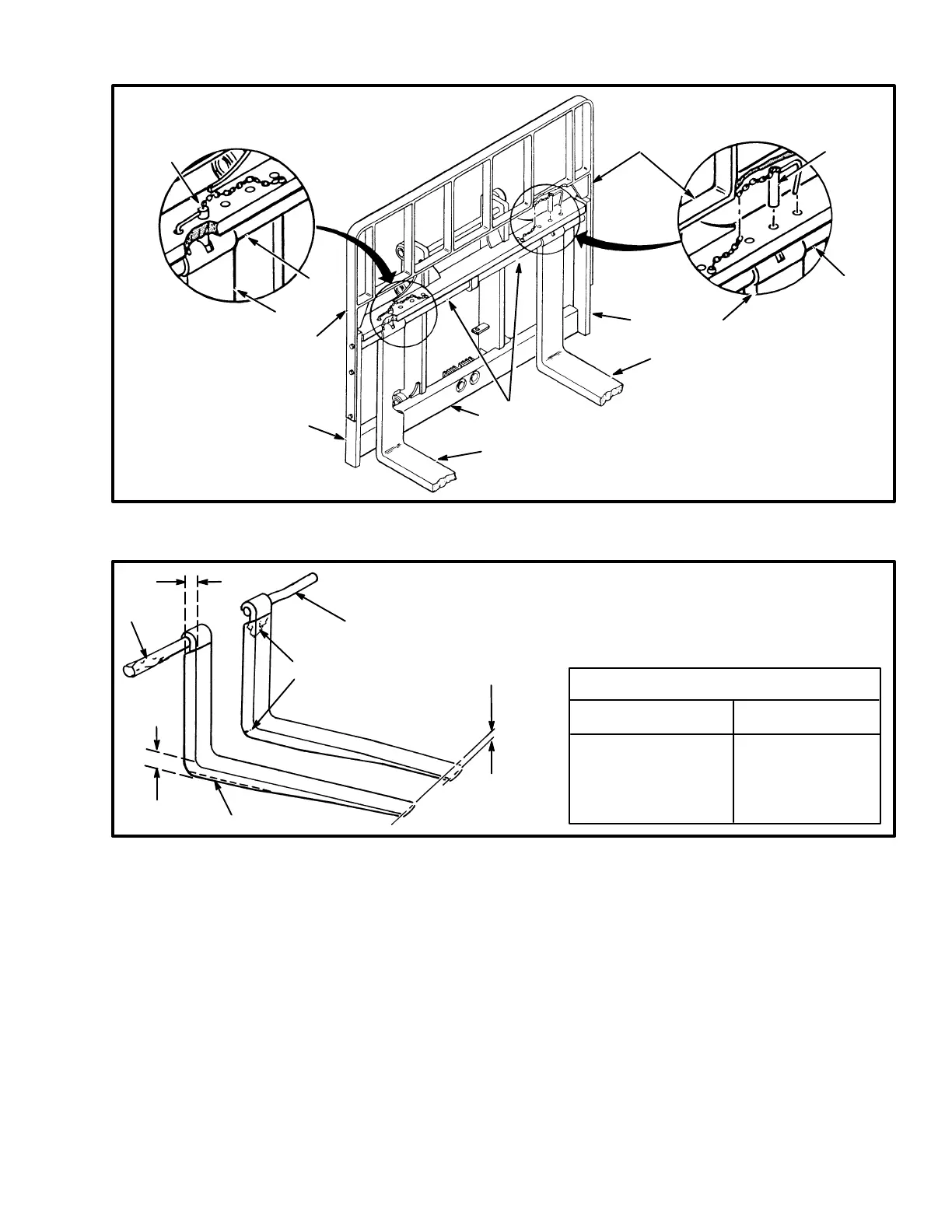

1. CARRIAGE

2. FORK

3. FORK PIN

4. LOCK PIN

5. LOAD BACKREST EXTENSION

FIGURE 13. PIN FORKS

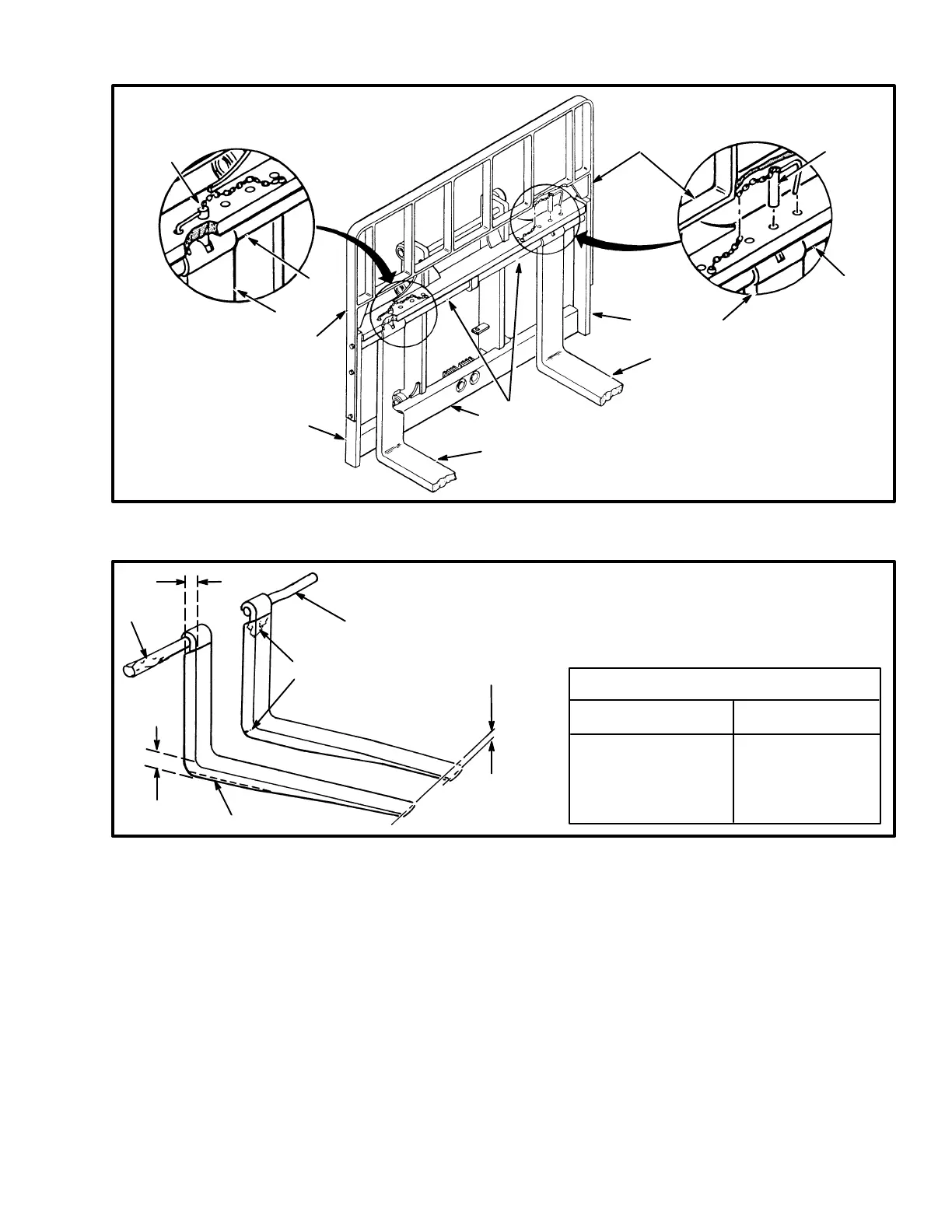

3. FORK PIN DAMAGE

4. MUST BE 90% OF

DIMENSION X

5. FORK WEAR

1

5

3

3

2

11195

X

4

1. TIP ALIGNMENT

(MUST BE WITHIN 3%

OF FORK LENGTH)

2. CRACKS

FORK TIP ALIGNMENT

LENGTH OF FORKS 3% DIMENSION

915 mm (36 in) 27 mm (1.10 in)

1220 mm (48 in) 37 mm (1.45 in)

1830 mm (72 in) 55 mm (2.15 in)

FIGURE 14. CHECK THE FORKS

1. Inspect the welds on the mast and carriage for cracks.

Make sure that the capscrews and nuts are tight.

2. Inspect the channels for wear in the areas where the

rollers travel. Inspect the rollers for wear or damage.

3. Inspect the load backrest extension for cracks and

damage.

4. Inspect the forks for cracks and wear. Check that the

fork tips are aligned within 13 mm (0.5 in) of each other.

(See FIGURE 14.) Check that the bottom of the fork is

not worn (Item 5).

5. Replace any damaged or broken parts that are used to

keep the forks locked in position.

6. If the lift truck is equipped with a side–shift carriage

or attachment, inspect the parts for cracks and wear.

Make sure the parts that fasten the side–shift carriage or

attachment to the carriage are in good condition.

7. Check that the lift chains are correctly lubricated. Use

SAE 30 engine oil to lubricate the lift chains.

8. Inspect the lift chains for cracks or broken links and

pins. (See FIGURE 15.)

Loading...

Loading...