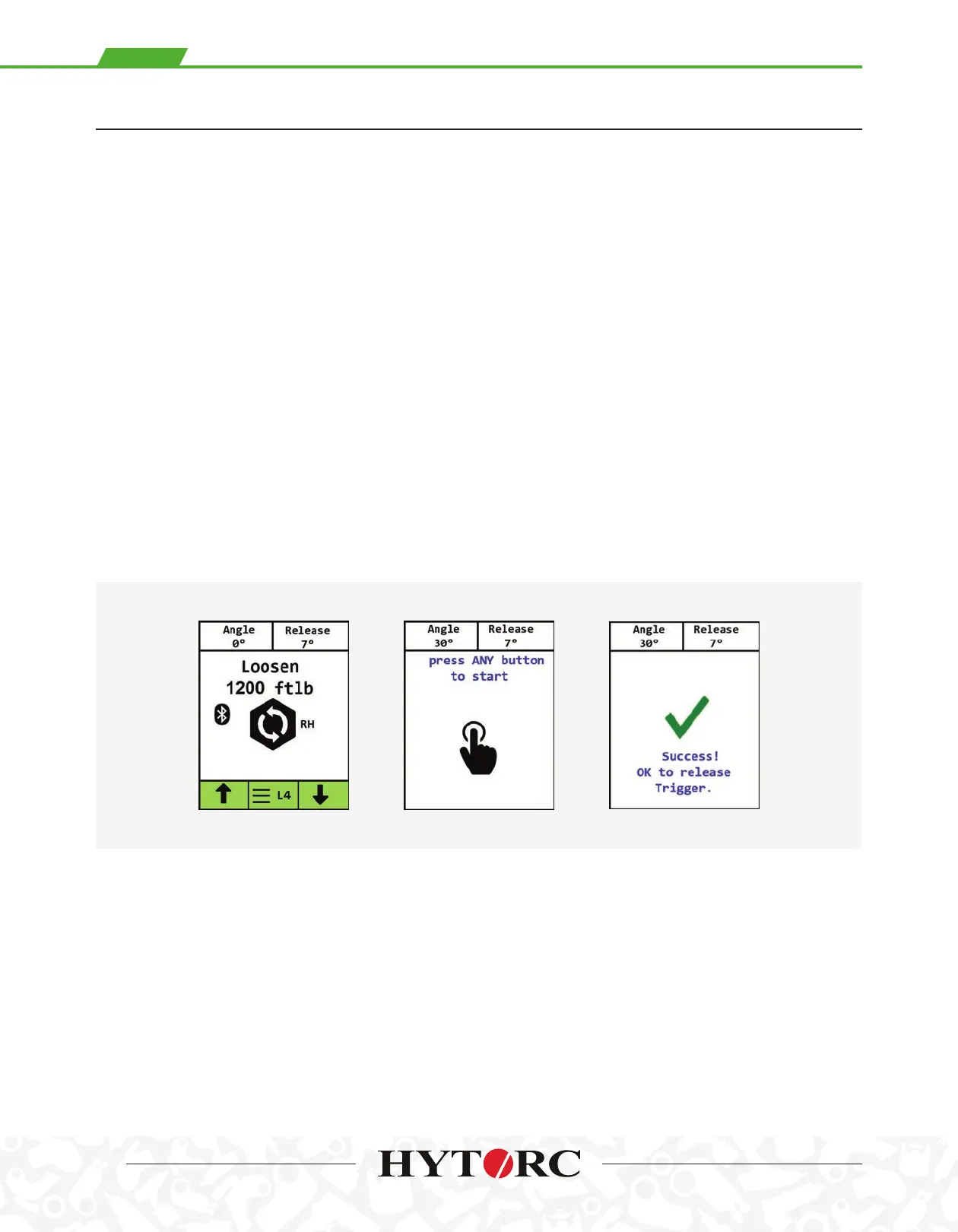

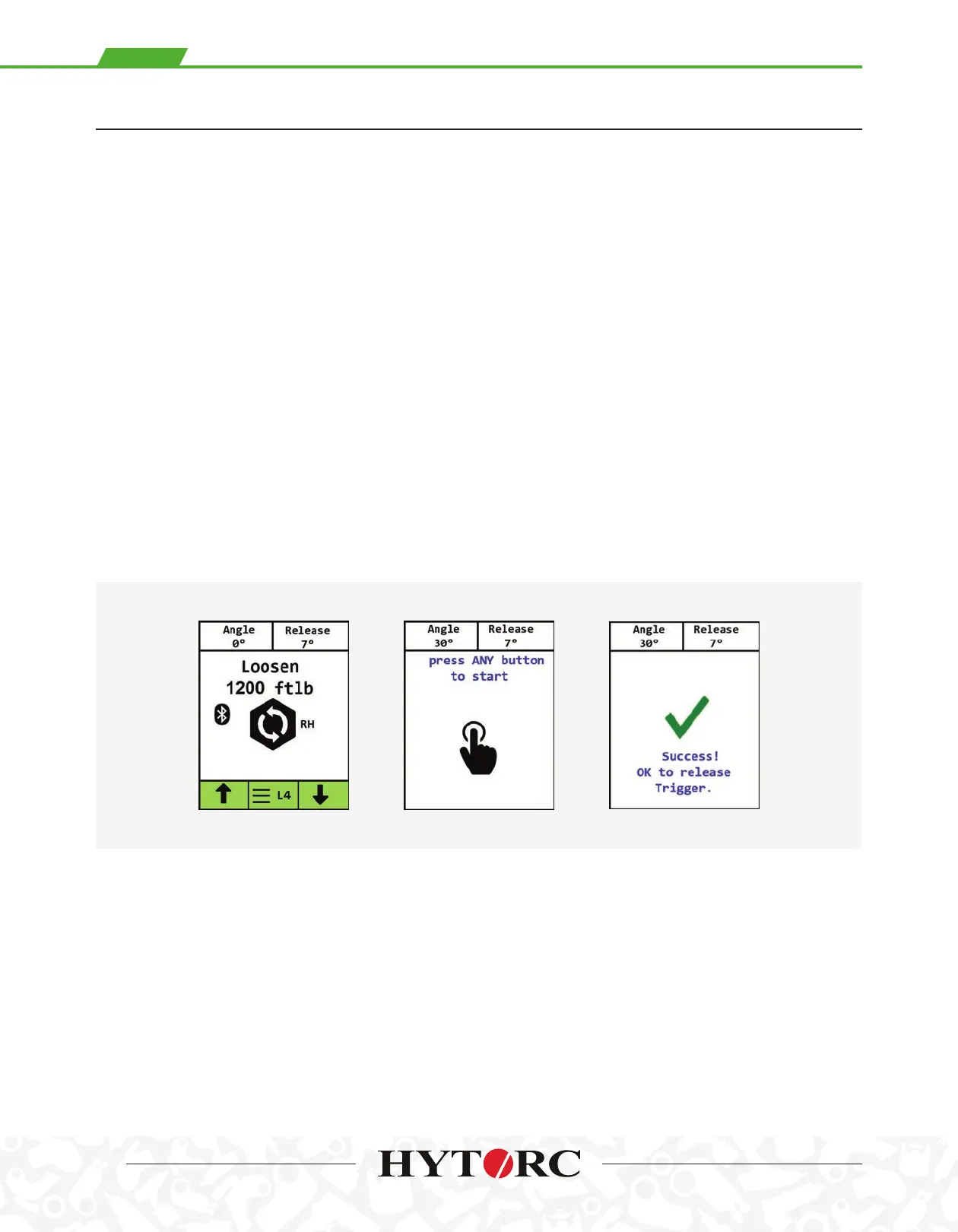

LOOSEN BOLT

• Setup Tool - Use the menu to specify the fastener type; e.g. LH, RH, HYTORC Washer.

• Set to Loosen - Toggle the direction switch to change from TORQUE to LOOSEN. The tool automatically sets the

Loosen Torque to the maximum calibrated value of the tool. The Loosen value may be adjusted by pressing the right

or left button to decrease or increase the value.

• Position Back Wrench - If needed, install back wrench to keep the back nut from turning.

• Position Tool on Nut - Make sure tool socket/driver is properly positioned on the nut.

• Position Reaction Arm - If a reaction arm is used, make sure the reaction arm is firmly abutted against a stationary

object (e.g. an adjacent nut, flange, equipment housing etc.).

• Pull Trigger to Loosen - If a RH or LH fastener has been specified the operator will be asked to push any button to

start. Press any button and continue to hold the trigger to carry out the loosening operation.

• Monitor Status - The status light is green in the loosen mode. Once the trigger is pulled the status light turns amber

during the operation. A a status light turning red indicates an error.

• Release Trigger – When the bolt is suiciently loosened release the trigger to stop loosening and verify nut is

completely loose.

(CONT’D.)

Loading...

Loading...