NS

MS

SV

ALM

Status indicator LEDs

BS-

BDL

BDH

BS+

Monitor LED : The board operation status and network conditions can be obtained.

CompoNet Communication Connector : XW7D-PB4-R (OMRON)

DO on the PCON / ACON / DCON side and Output Data Register

Remote I/O Mode

Position / Simple

Direct Value Mode

Half Direct Value

Mode

Full Direct Value

Mode

*4

Remote I/O Mode2

Parameter No.84 : 0

(Set in delivery)

Parameter No.84 : 1 Parameter No.84 : 2 Parameter No.84 : 3 Parameter No.84 : 4

PLC Output

Area

*3

Number of Occupied

Channels : 1CH

Number of Occupied

Channels : 4CH

Number of Occupied

Channels : 8CH

Number of Occupied

Channels : 16CH

Number of Occupied

Channels : 6CH

n+6 Alarm Code Alarm Code

n+7 Status Signal

n+8

n+9

Occupied Domain

n+10

n+11

Total Number of

Movement

n+12

n+13

Total Number of

Drive

n+14 Status Signal 1

n+15

Status Signal 2

*1 The Occupied Domain shows the domain to be occupied with the operation mode setting.

Therefore, this domain cannot be used for any other purpose. Also, be careful of using duplicated node addresses.

*2 When an alarm is sounded, the completion position No. (4 bits for PM1 to PM8) shows the simple alarm code.

*3 The unit differs for each field network.

・DeviceNet or CompoNet : CH Number

・PROFIBUS-DP or MECHATROLINK : byte address

*4 It is not applicable for MECHATROLINK-Ⅰ/Ⅱ

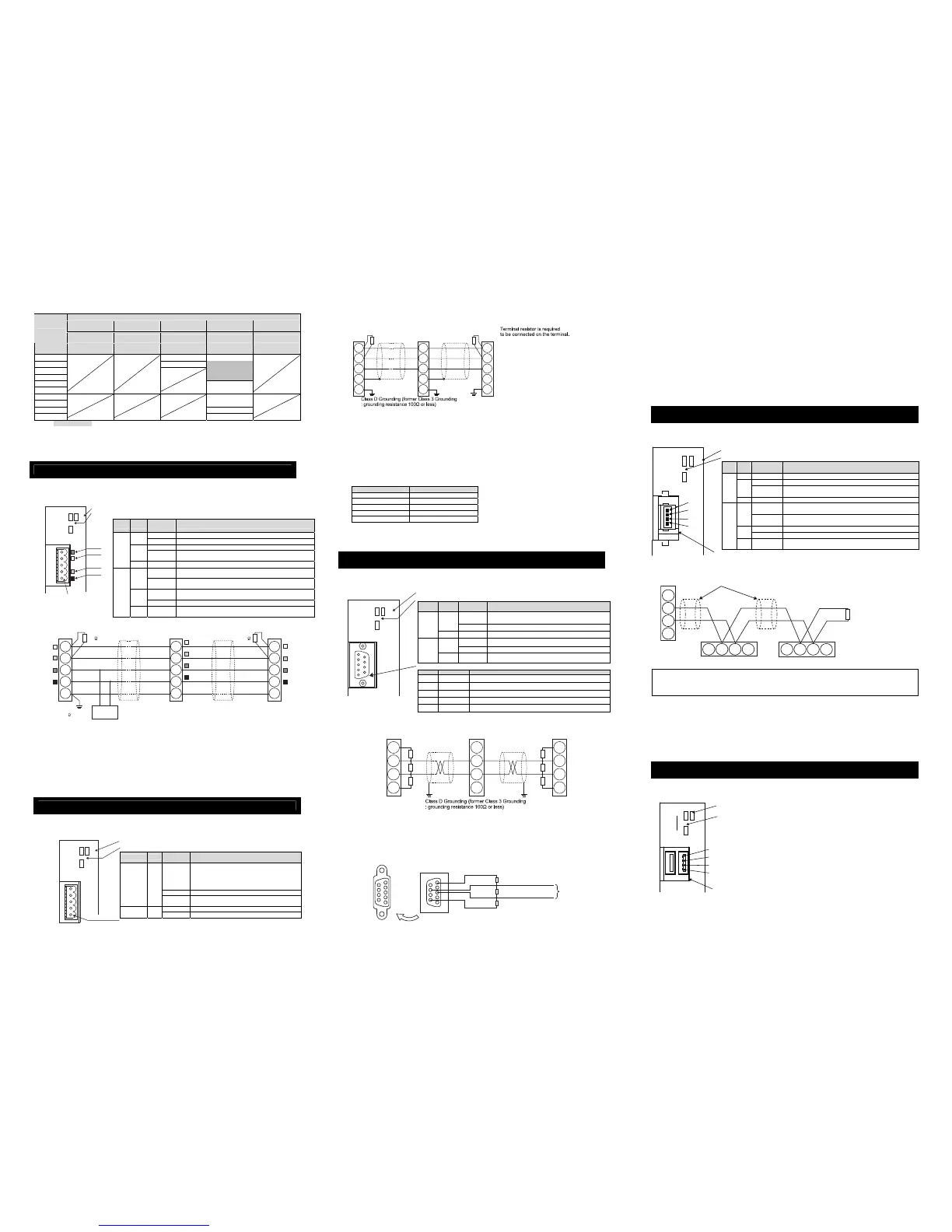

DeviceNet

● Specification

Refer to section DeviceNet instruction manual (ME0256).

● Interface Section

LED color

Indication

Status

Description

Illuminating

Normal operation

GN

Flashing

Hardware Error. It might be recovered with reconnect of the power.

Illuminating

Hardware Error. The replacement of the board is required.

OR

Flashing

It is a minor error such as a user setting error or configuration error.

It can be recovered by re-setting, etc.

MS

-

OFF

The DeviceNet is being initialized, or the power is not supplied.

Illuminating

The connection has been established and the communication is

being performed normally.

GN

Flashing

The machine is on-line, but the connection has not been

established. Communication Stop (Network is normal).

Illuminating

Node address is duplicated or Busoff is detected.

Communication Unavailable.

OR

Flashing

Communication Error (Communication Time-out Detection)

NS

- OFF

The machine is not on-line.

The power to the DeviceNet is not supplied.

● Wiring

● Operation Mode Setting and Address Allocation

The operation mode is set using the parameters.

Set the mode change switch on the front of the board to “MANU” side and set the parameter No. 84 “FMOD: Fieldbus

Operation Mode” using the Personal Computer Application Software for RC. [Refer to Address Map]

● Station No. Setting

The station No. is set using specific parameters.

Set the parameter No.85 “NADR: Fieldbus Node Address” using the personal computer application software for RC.

Settable Range:0 to 63 (It is set to “63” when the machine is delivered from the factory.)

● Communication Speed Setting

The setting for the communication speed is not required because it automatically follows the master’s communication speed.

(Note)

After the parameter setting, cycle the control power, and return the mode toggle switch on the front of the controller to “AUTO” side.

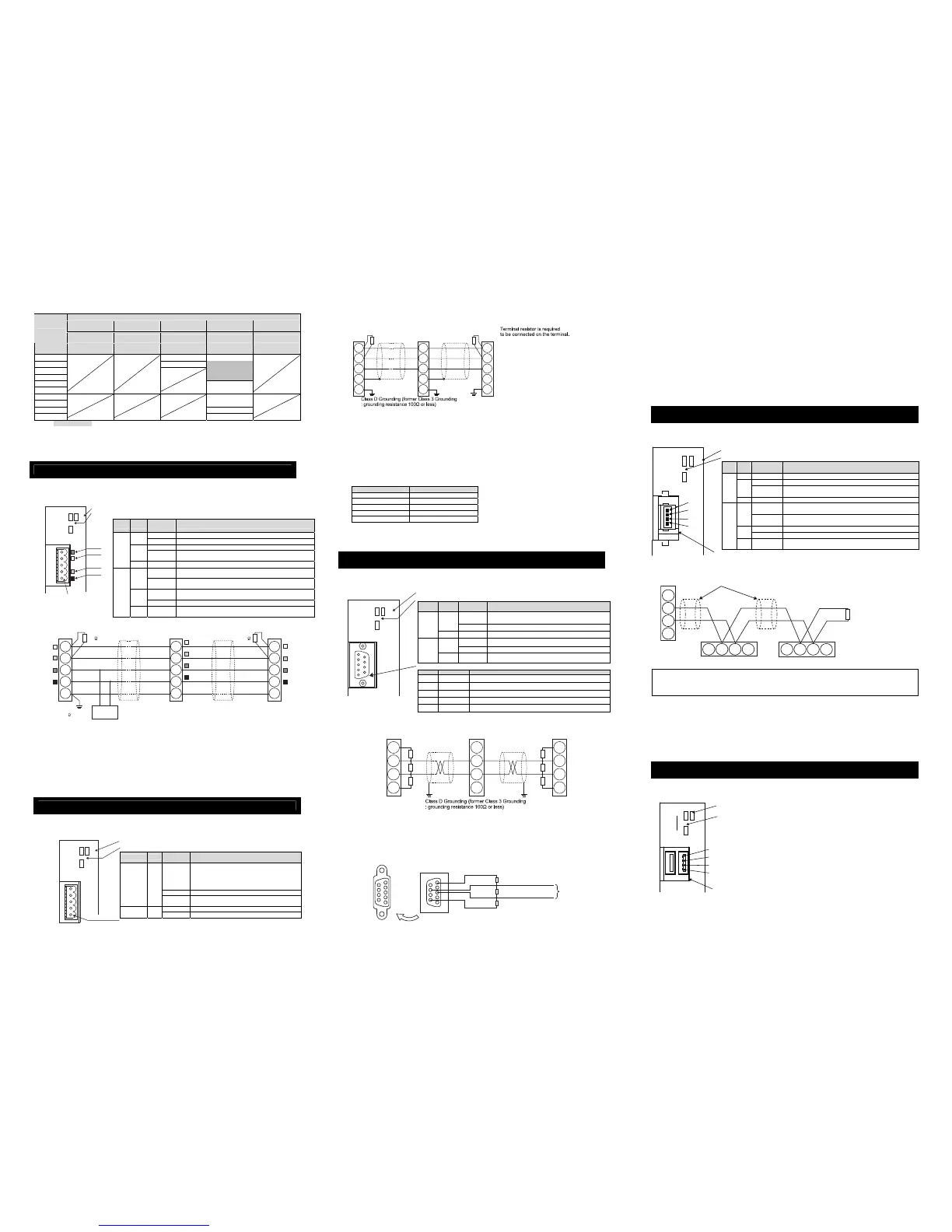

CC-Link

● Specification

Refer to section CC-Link instruction manual (ME0254).

● Interface Section

LED Color

Indication

Status

Indication Description

(Meaning of the Indication)

Illuminating

• An error occurs.

(CRC Error/Station No. (parameters) Setting

Error/Baud Rate Setting (parameters) Error)

• Period between the power injection or software

reset and the CC-Link initialization completion

OFF • Under Normal Communication

ERR OR

Flashing

• Station No. setting or communication speed

setting is changed during the communication.

Illuminating • Under communication

RUN GN

OFF • Not communicated

● Wiring

● Operation Mode Setting and Address Allocation

The operation mode is set using the parameters.

Set the mode change switch on the front of the board to “MANU” side and set the parameter No.84 “FMOD:

Fieldbus Operation Mode” using the Personal Computer Application Software for RC.

● Station No. Setting

The station No. is set using specific parameters.

Set the parameter No.85 “NADR: Fieldbus Node Address” using the personal computer application software for RC.

Settable Range : 1 to 64 (Already set in system delivery)

● Communication Speed Setting

Set the parameter No.86 “FBRS: Fieldbus Communication Speed” using the personal computer application

software for RC.

Set Value Communications speed

0 (Set in delivery) 156kbps

1 625kbps

2 2.5Mbps

3 5Mbps

4 10Mbps

(Note) Set the Station Data for the Master Station to “ver 1, Remote Device Station”.

(Note) After the parameter setting, cycle the control power, and return the mode toggle switch on the front of the

controller to “AUTO” side.

PROFIBUS-DP

● Specification

Refer to section PROFIBUS-DP instruction manual (ME0258).

● Interface Section

LED Color

Indication

Status

Indication Description (Meaning of the Indication)

Illuminating

The communication is being performed normally from the

fieldbus in online mode.

GN

Flashing The machine is in offline mode from the fieldbus

NS

OR Flashing A communication error is caused.

Illuminating The machine is in the normal operation.

GN

Flashing Preparation for the operation is performed.

MS

OR Illuminating

A communication hardware error was detected in the

operation preparation mode.

Pin No. Description Contents

3 B-Line RxD·TxD(Communication Line on the Plus Terminal Side)

5 GND Signal Cable Grounding (Insulated)

6 +5V +5V Output (Insulated)

8 A-Line /RxD·/TxD (Signal Line on the Minus Terminal Side)

Housing Shield Cable Shield (for Case and Connection)

● Wiring

● Bus Terminal Treatment

When the line is connected to the network terminal, connect the terminal resistance to the

PROFIBUS-DP communication connector as shown in the following figure, or use the connector with the

terminal resistance.

•

Example of using the connector with the terminal resistance : SUBCON-PLUS-PROFIB/AX/SC (PHOENIX CONTACT)

• Connection of the Terminal Resistance

● Operation Mode Setting and Address Allocation

The operation mode is set using the parameters.

Set the mode change switch on the front of the board to “MANU” side and set the parameter No. 84 “FMOD :

Fieldbus Operation Mode” using the Personal Computer Application Software for RC.

● Station No. Setting

The station No. is set using specific parameters.

Set the parameter No.85 “NADR: Fieldbus Node Address” using the personal computer application software for RC.

Settable Range : 0 to 125 (It is set to “1” when the machine is delivered from the factory.)

● Communication Speed Setting

The setting for the communication speed is not required because it automatically follows the master’s

communication speed.

(Note) After the parameter setting, cycle the control power, and return the mode toggle switch on the front of the

controller to “AUTO” side.

CompoNet

● Specification

Refer to section CompoNet instruction manual (ME0220).

● Interface Section

LED Color

Indication

Status

Description

GN Illuminating In the normal operation

Illuminating Hardware Error. The replacement of the board is required.

RD

Flashing

It is a minor error such as a user setting error or configuration

error. It can be recovered by re-setting, etc.

MS

- OFF The CompoNet is being initialized, or the power is not supplied.

Illuminating

The connection has been established and the communication is

being performed normally.

GN

Flashing

The machine is on-line, but the connection has not been

established. Communication Stop (Network is normal).

Illuminating A duplicated node address is considered.

RD

Flashing Communication Error (Communication Time-out Detection)

NS

- OFF

The machine is not on-line.

The power is not supplied.

● Wiring

* Comnication supply power is not required.

However, when multiple power supply is to be conducted to another slave, there would be no problem

even if connecting to the communication power to BS+ and BS- terminals.

● Station No. Setting

The station No. is set using specific parameters.

Set the parameter No.85 “NADR: Fieldbus Node Address” using the personal computer application software for RC.

Settable Range : 0 to 63 (It is set to “0” when the machine is delivered from the factory.)

(Note) The setting for the communication speed is not required because it automatically follows the master’s

communication speed.

(Note) After the parameter setting, cycle the control power, and return the mode toggle switch on the front of the

controller to “AUTO” side.

MECHATROLINK-Ⅰ/Ⅱ

● Specification

Refer to section MECHATROLINK instruction manual (ME0221).

● Interface Section

NS

MS

SV

ALM

Red

White

Blue

Black

DeviceNet Communication

Connector

: MSTB2.5/5-GF-5.08AU

(PHOENIX CONTACT)

Status indicator LEDs

Monitor LED : The board operation status and network conditions can be obtained.

ERR

SV

ALM

FG

SLD

DG

DB

DA

Status indicator LEDs

Status LED : The board operation status and network conditions can be obtained.

CC-Link Communication Connector : MSTB2.5/5-GF-5.08AU (PHOENIX CONTACT)

RUN

* Prepare for 9 pin male D-sub connector at Cable side connector.

NS

SV

ALM

Status indicator LEDs

Status LED : The board operation status and network conditions can be obtained.

PROFIBUS-DP Communication Connector : 9 pin female D-sub

MS

1

STATUS

0

SV

ALM

Status LED : The board operation status and network conditions can be obtained.

Status indicator LEDs

MECHATROLINK Communication Connector : DUSB-ARB82-T11A-FA (DDK)

NC

/DATA

DATA

SH

Loading...

Loading...