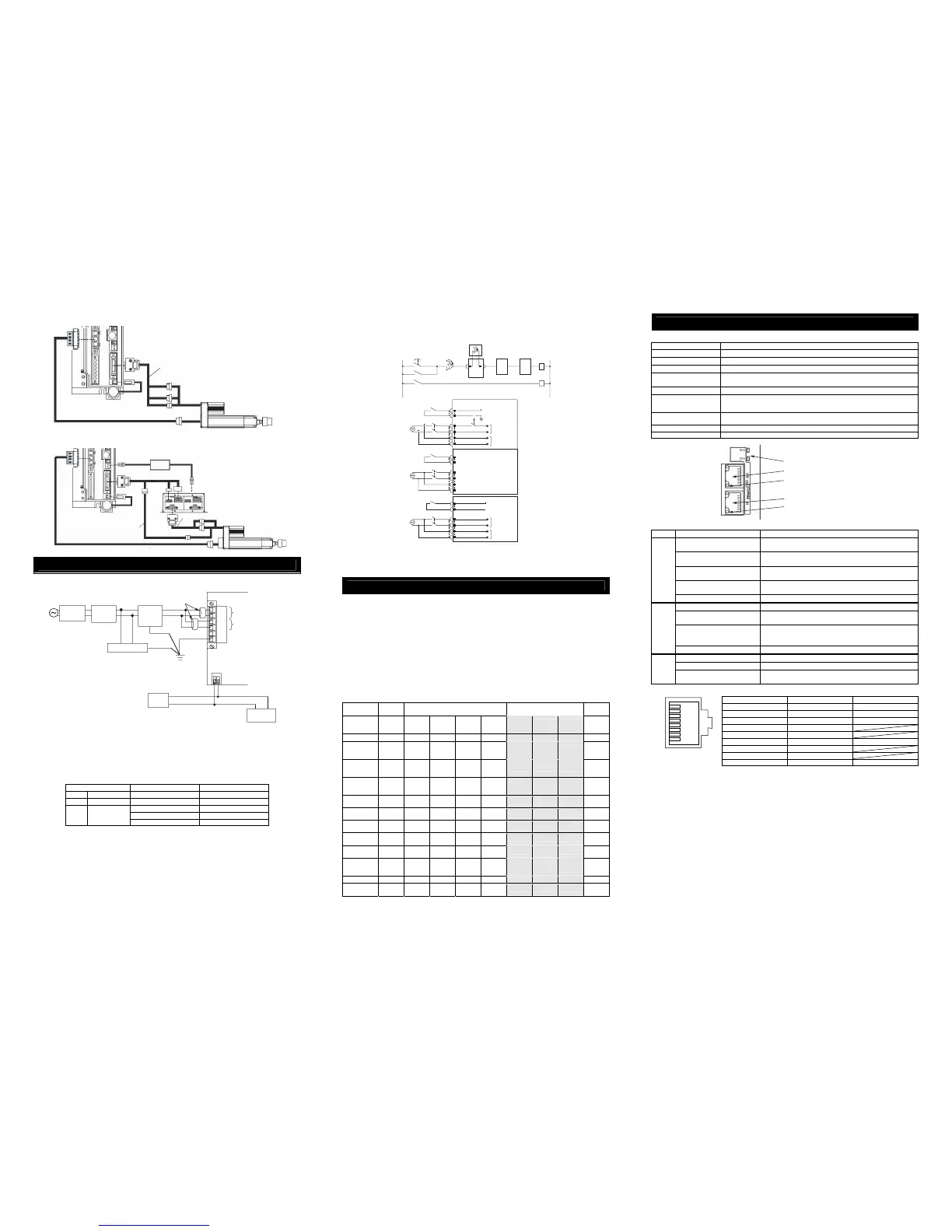

● RCS2-RA13R Equipped with no Brake, with Loadcell in SCON-CA

● RCS2-RA13R Equipped with Brake and Loadcell in SCON-CA

Power Supply and Emergency Stop Circuit

● Wiring for Power Supply (to be prepared by customer)

NF

*3

SK

*2

+24V

0V

L1

L2

L1C

L2C

NC

PE

BK+

PWR-

100V AC

or

200V AC

(Refer to Controller

Power Voltage Specifications)

Circuit

Breaker

Ground Fault

Circuit

Interrupter

CLF

*1

Class D grounding

(Formerly Class-III grounding)

24V DC

Power

Supply

SCON

AC Power Supply

Input Connector

B. Motor Power Unit

A. Control power supply

Brake Power Supply

Input Connector

Brake

Release Box

Power consumption of SCON varies depending on the connected actuator, etc. Select the circuit breaker that suits to the

specification.

[Refer to Basic Specifications]

A ground fault circuit interrupter needs to be selected carefully considering the purposes of prevention of fire and protection

of human.

Have a measurement of the leak current where a ground fault circuit interrupter is to be installed.

Use the “harmonic type” for the ground fault circuit interrupter.

*1 CLF : Clamp Filter … It is recommended to attach it to improve noise immunity.

*2 SK : Surge Killer … It is recommended to attach it to improve noise immunity.

*3 NF : Noise Filter … Make sure to install it. It is recommended to have it installed within 0.3m of the cable length from

SCON.

Parts Name Maker Model

CLF Clamp Filter TDK ZCAT3035-1330

SK Surge Protector Okaya ELECTRIC CO.,LTD R·A·V-781BWZ-2A

COSEL NAC-10-472

SOSHIN ELECTRIC CO.,LTD NF2010-UP

NF Noise Filter

DENSEI-LAMBDA MC1210

● Wiring for Emergency Stop Input

The following diagram shows an example of how the emergency stop switch for the teaching pendant may be

included in the emergency stop circuit you may construct.

Note 1 When the teaching pendant is not connected, S1 and S2 become short-circuited inside the controller.

Note 2 Connect a contactor to L1 and L2 terminals for external power cutoff by the emergency stop if the motor power is

required to be cut off externally to comply with the Safety Categories.

Note 3 The rating for the emergency stop signal to turn ON/OFF at contact CR1 is 24V DC and 10mA.

Note 4 For CR1, select the one with coil current 0.1A or less.

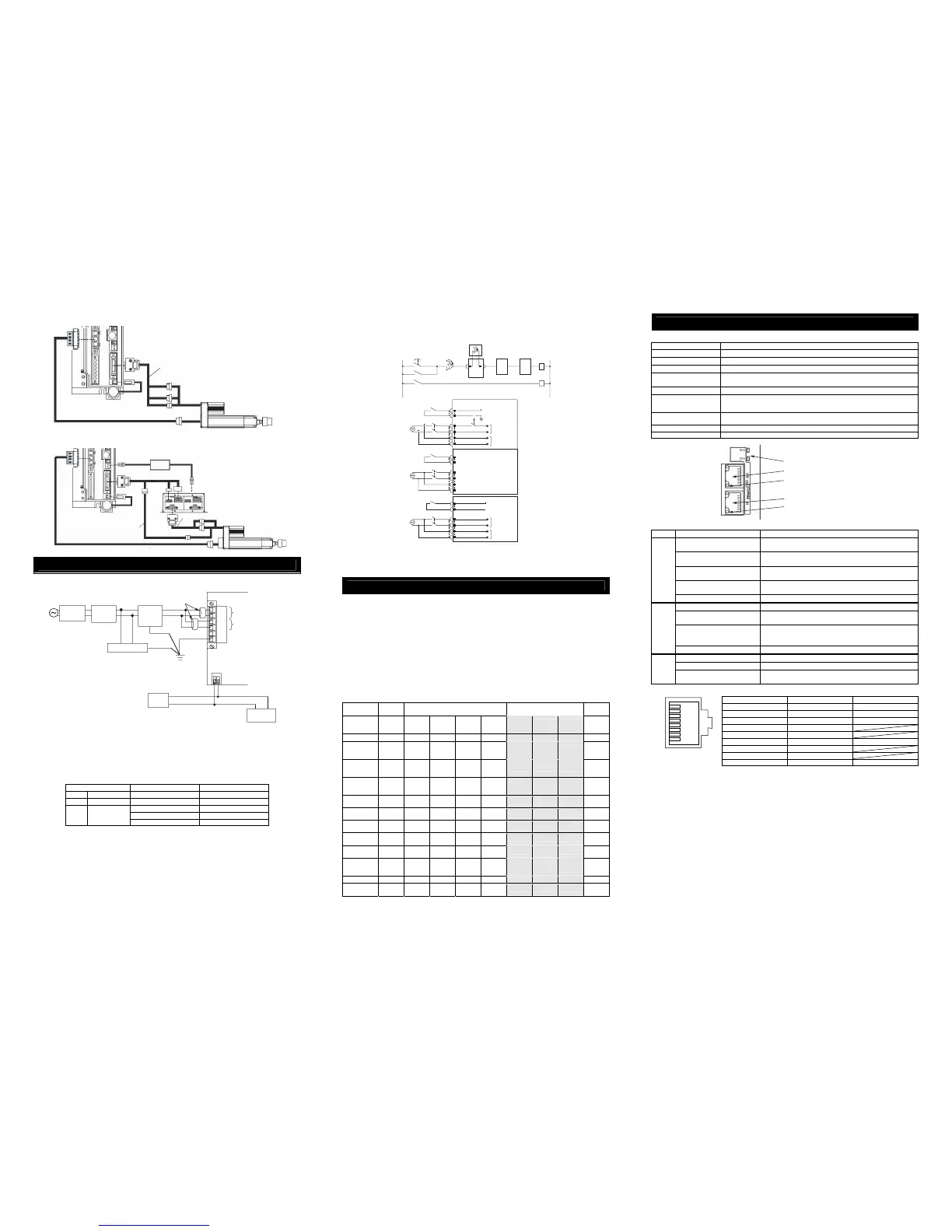

Operation Modes and Functions (in common for each Fieldbus)

SCON-CA Type is available for all the operation modes in the next table.

SCON-CAL/CGAL Type is available for the operations in the modes except for those in the shaded area in

the next table.

(1) Remote I/O Mode : This is the mode to perform operation by PIO (24V I/O) with Fieldbus.

(2) Position / : This is the mode to perform operation by indicating the target position by inputting the value directly.

Simple Direct Mode The values of the position data already registered for the speed, acceleration/deceleration and

positioning band are to be used in this mode.

(3) Half Direct Mode : This is the operation mode to indicate the speed, acceleration/deceleration and pressing

current, as well as the target position, by inputting the values directly.

(4) Full Direct Mode :

This is the operation mode to indicate all related to the position control by inputting the values directly.

(5) Remote I/O Mode 2 :

This is the mode that the function to read the current position and the current speed is added to Remote I/O.

(6) Position / : This is the mode corresponding to the force control function instead of the teaching and zone

Simple Direct Mode 2 functions in (2).

(7) Half Direct Mode 2 :

This is the mode that enables to read the loadcell data instead of reading the command current value in (3).

(8) Remote I/O Mode 3 :

This is the mode that the function to read the current position and loadcell data is added to (1) functions.

(9) Half Direct Mode 3 : This is the mode that equips the vibration control function instead of the jog function in (3).

Operation Modes and Main Functions

Corresponding

Type

All the

Types

CA/CAL/CGAL Type

Dedicated for CA Type

CA/CAL/

CGAL Type

Main Functions

Remote I/O

Mode

Position /

Simple Direct

Mode

Half Direct

Mode

Full Direct

Mode

Remote I/O

Mode 2

Position /

Simple Direct

Mode 2

Half Direct

Mode 2

Remote I/O

Mode 3

Half Direct

Mode 3

Occupied Bytes

2 8 16 32 12 8 16 12 16

Position No.

Designated

Operation

○ ○ × × ○ ○ × ○ ×

Position Data

Designated

Operation

× ○

(Note 1)

○ ○ × ○

(Note 1)

○ × ○

Speed, Acceleration

and Deceleration

Direct Designation

× × ○ ○ × × ○ × ○

Pressing

Operation

○ ○ ○ ○ ○

○ ○ ○ ○

Current Position

Reading

× ○ ○ ○ ○ ○ ○ ○ ○

Current Speed

Reading

× × ○ ○ × × ○ × ○

Completed Position

No. Reading

○ ○ × × ○ ○ × ○ ×

Max. Number of

Position Tables

512 768

Not

Applicable

Not

Applicable

512 768

Not

Applicable

512

Not

Applicable

Force Control

(Specified only

for SCON-CA)

△

(Note 2)

× × ○ △

(Note 2)

○ ○ △

(Note 2)

×

Vibration Control

○

○ × ○ ○ ○ × ○ ○

Servo Gain

Changeover

○ ○ ○ ○ ○

○ × ○ ○

(Note 1) Operation is to be performed with designating the position No. for the position data except for Position Data.

(Note 2) It is available when the PIO pattern is set on either 6 or 7. However, SCON-CAL/CGAL is not applicable for PIO

Patterns 6 and 7.

EtherCAT®

● Specification

Item Specification

Communication protocol IEC61158Type12

Physical layer 100BASE-TX (IEEE802.3)

Communication speed Automatically follows the Master

Communication cable

length

Depends on EtherCAT® Specification (Distance between each node: 100m

max.)

Slave type I/O slave

Applicable node address 0 to 127

(17 to 80 : When connected to the master (CJ1W-NC*82) manufactured by

OMRON)

Communication cable Category 5e or more

(Double shielded cable braided with aluminum foil recommended)

Connector RJ45 Connector × 2pcs (Input × 1, Output × 1)

Connection Daisy chain only

● Interface Section

● Status LED Displays of EtherCAT® Type

Name Indication Color Description

OFF

Initial condition (EtherCAT® communication in “INIT”

condition) or the power is OFF

GN (Illuminating)

In normal operation (EtherCAT® communication in

“OPERATION” condition)

GN (Flashing)

(ON:200ms/OFF:200ms)

(EtherCAT® communication in “PRE-OPERATION” condition)

GN (Flashing)

(ON:200ms/OFF:1000ms)

(EtherCAT® communication in “SAFE-OPERATION” condition)

RUN

OR (Illuminating) Communication component (module) error

OFF No abnormality or the power is OFF

OR (Flashing)

(ON:200ms/OFF:200ms)

Construction information (settings) error

(Information received from the master cannot be set)

OR (Flashing)

(ON:200ms × 2 times

/OFF:1000ms)

Communication section circuit error

(Watchdog timer timeout)

ERR

OR (Illuminating) Communication component (module) error

OFF Link status not detected or the power is OFF

GN (Illuminating) Linked (No network congestion)

Link/

Activity

GN (Flashing)

(ON:50ms/OFF:50ms)

Linked (Network in congestion)

● EtherCAT® Connector

Pin No. Signal Name Abbreviated Code

1

Data sending + TD+

2

Data sending − TD−

3

Data receiving + RD+

4 Not used

5 Not used

6

Data receiving − RD−

7 Not used

8 Not used

Connector Hood Security grounding FG

● Operation Mode Setting and Address Allocation

The operation mode is set using the parameters.

Set the mode change switch on the controller front panel to “MANU” side and set the parameter No. 84

“FMOD: Field Bus Operation Mode” using the teaching tool such as PC software for RC.

[Refer to the Instruction Manual for the details]

● Node address setting

The node address is set using specific parameters.

Set the parameter No. 85 “NADR: Field Bus Node Address”using the teaching tool such as PC software

for RC.

Settable Range : 0 to 127 (It is set to 17 which is the I/O slave top address of EtherCAT® at the delivery.)

● Communication Speed Setting

It is not necessary to do any settings because it automatically follows the communication settings applied

to the master for the communication frequency.

(Note) After parameter setting, reset the controller mode change witch to “AUTO” side, and then cycle the

controller power.

CB-RCS2-PLLA

RCS2-RA13R

(with Loadcel)

Absolute Battery

(for Absolute Type)

Status LED (RUN/ERR)

EtherCAT® Output Port

Link/Activity LED (Output)

EtherCAT® Input Port

Link/Activity LED (Input)

CB-LDC-CTL□□□-JY

CB-RCS2-PLLA

RCS2-RA13R

(with Loadcell and Brake)

CB-RCS2-PLA (enclosed to Brake Box)

24V DC

Brake Box

RCB-110-RA13-0

Connect to back side

Absolute Battery

(for Absolute Type)

Power Supply for Brake

1

8

RJ45 8-pin

Modular Connector

(Controller Side)

24V

Emergency stop

reset switch

Emergency stop

switch

Emergency stop switch

for the teaching pendant

(Note 1)

SCON

First unit

SCON

Second

unit

SCON

Nth unit

S1 S2 S1 S2 S1 S2

CR1

(Note 1)

0V

MC1

CR1

CR1

CR1

(Note 1)

MC1

(Note 2)

AC100V

AC200V

SCON-CA/CAL

SCON-CGAL

EMG+

EMG-

L1

L2

L1C

L2C

24V

Motor power cutoff relay

Motor

power supply

Control

power supply

CR1

(Note 1)

MC1

(Note 2)

AC100V

AC200V

EMG+

EMG-

L1

L2

L1C

L2C

SCON-CA/CAL

Second unit

EMG-

EMG+

CR1

(Note 1)

24V

MC1

(Note 2)

AC100V

AC200V

L1

L2

L1C

L2C

Motor

power supply

Control

power supply

Loading...

Loading...