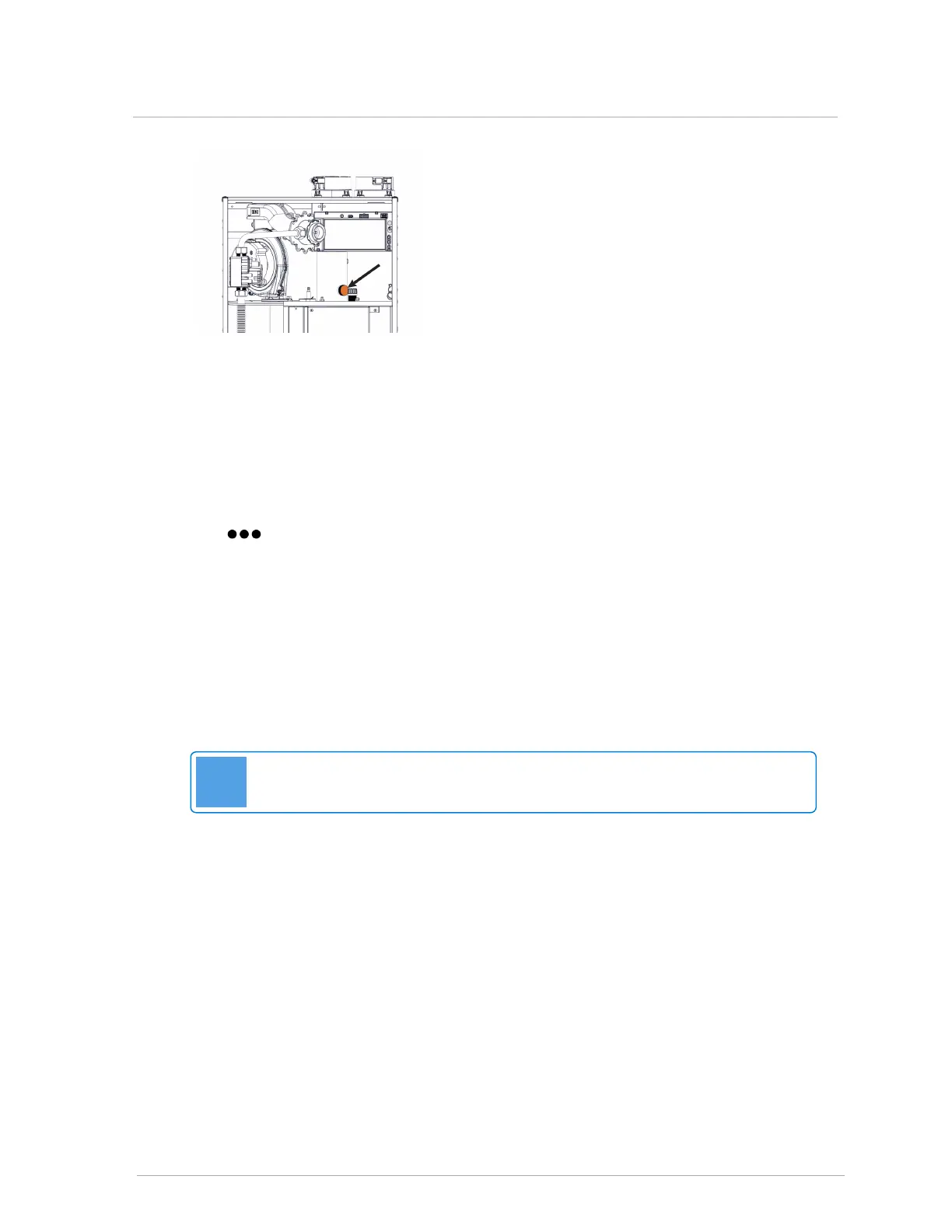

Figure 43 Flue gas test port

4. Adjust the high fire according to values in Table 10 using a Torx 15 screwdriver. Turn the

screwdriver clockwise no more than a maximum of one full rotation at a time to raise the

CO

2

% (to richen). Turn counter-clockwise no more than a maximum of one full rotation at a

time to lower CO

2

%.

5.

Set the heat-out value in Test Operation mode to the minimum MBH for the boiler. To do this,

go to > Test Operation > In the Fan Test: Heat Out field, tap 0 MBtu, then enter the

minimum MBH.

6. Adjust the low fire according to values in Table 10 using a Torx 15 screwdriver. Turn the

screwdriver clockwise to raise the CO

2

% (to richen). Turn counter-clockwise to lower

CO

2

%. Start with ⅛ of a turn until you see the analyzer measure a change then only make

1/16 adjustments. If changing direction on this adjustment you may notice a significant

backlash.

7.

Check the results and confirm the correct settings when you return the boiler to high fire, and

then to low fire.

Note

Clock the gas meter to confirm full maximum rating plate input.

8. To exit the Test Operation screen, select Back.

9. Remove the call for heat.

10. If a manometer is connected to the gas valve inlet gas pressure port:

a. Turn off the gas supply at the external gas shut-off valve.

b. Disconnect the manometer.

c. Tighten the inlet pressure port screw with a Torx 15 screwdriver.

11. Remove the analyzer probe, and install the test port plug.

12. Turn on the gas supply shut off valve.

6.3.3 Adjusting the gas valve

Loading...

Loading...