INSTALLATION AND OPERATION INSTRUCTIONS

1-6

VFC 15-150 - VFC 45-225 MODULATING GAS BOILERS

1.4.3 Vent Travel

3" PPs (rigid single wall) or CPVC ULC-S636 approved piping is the standard

venting option; with this, the VFC 15-150 boiler can be sited up to 120 equivalent

feet from the vent termination (for the VFC 45-225, up to 240' equivalent). The

actualventtravelallowanceisreducedforttingsinaccordancewithTable 3. –

e.g. for a VFC 15-150 using 4 x 90º CPVC elbows, the maximum lineal measure

of pipe allowed is 88 feet (120'–(4 x 8'= 32) = 88'). For the 15-150 model, vent

installationsrequiringonlyshorttravelcanbesatisedusing2'or2-1/2"pipe.

Flexible PPs can be used, but the allowances change as follows:

•

Up to 60 lineal feet of 3” venting is allowed in nominally vertical orientation (>45°).

• Further travel is permitted using rigid single wall PPs (VFC 15-150 up to 30’

equivalent; VFC 45-225 up to 60’ equivalent).

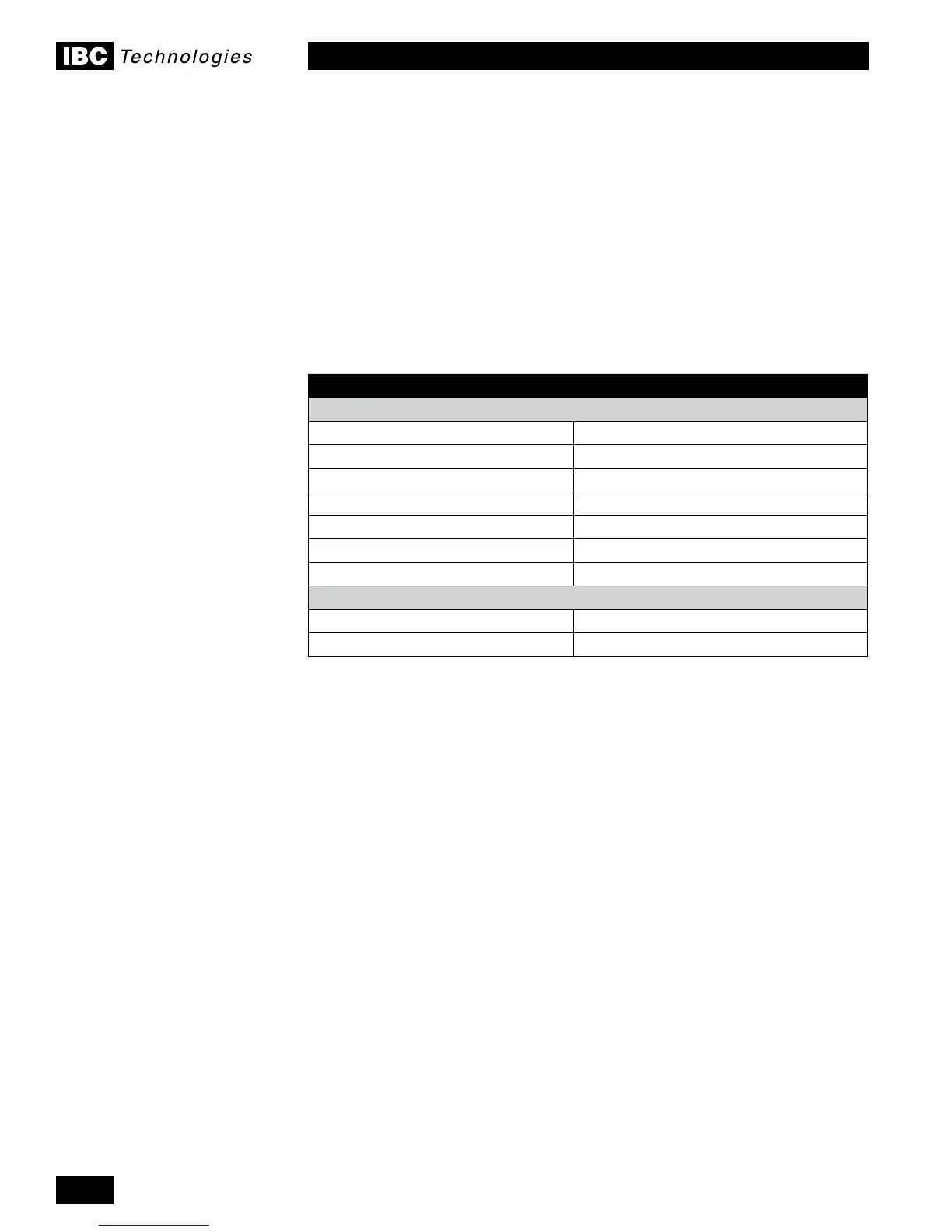

EXHAUST PIPE SIZE MAXIMUM EQUIVALENT LENGTH

Sched.40; Rigid PPs

2" (15-150 only) 50' (each side)

2-1/2" (15-150 only) 70'

3" (15-150) 120'

3" (45-225) 240'

90° vent elbow allow 8' equivalent

45° elbow allow 3’ equivalent

PPs 87-90° elbow use 8’ equivalent

Flexible PPs

2” Flexible 60’ (see Note 1)

3” Flexible 60’ (see Note 1)

Table 3: Maximum exhaust venting length

NOTE 1:

Plus up to 30’ (15-150) or 60’ (45-225) equivalent in rigid PPs can

be used.

NOTE 2: Unused intake travel cannot be added to the exhaust. Unequal

intake and exhaust piping is allowed - see Section 1.4.8.

VFC 15-150: when using the 3” venting option a 3" x 2" reducer must be placed

in a vertical section of the ue gas vent (within 3' of the boiler), to avoid pooling of

condensate. Similar comments apply to the 15-150’s 2-1/2" venting option – see

below. The VFC 45-225 transitions to 3” using the 3” x 2” reducing tee supplied in

its vent kit.

Certain installations of the 15-150 model can employ the 2" vent options. This

would typically involve a 15 lineal foot run up to the ceiling joists and outside,

using perhaps 3 x 90° elbows on each of the exhaust and intake. We do not

recommend horizontal runs using 2" pipe except near the base of the boiler,

upstream of the condensate drain. See Section 1.5 Condensate Removal.

Reason:airfrictionfromthefastmovingexhaustathigh-reina2"pipe

overcomes gravity on 1/4" / foot vent slope – leaving a pool of condensate at the

nextupturnedelbow.Poolingcanimpairtheachievementoffullhigh-rerating

plate performance.

Again for the 15-150 model only, there is a further 2-1/2" vent option that offers

some middle ground – it can be applied to runs of up to 70' equivalent length for

each side, without the limitation on horizontal runs as the for 2" option.

Loading...

Loading...