1-5

INSTALLATION

VFC 15-150 - VFC 45-225 MODULATING GAS BOILERS

For long vent runs with higher initial exhaust temperature, some jurisdictions

may allow the use of mixed materials for economy: ULC-S636 approved CPVC

for the initial run followed by ULC-S636 approved PVC to the termination (It is

the responsibility of the Installer to conrm that local codes will allow this option).

Ensure appropriate transition glue is used. The installer is responsible to ensure

thatsufcienttemperaturelossisallowedforintheCPVCsectiontofallbelow

the limit for PVC, taking into account the highest possible ambient temperature in

the area of vent travel (e.g. boiler room, attic and/or chase).

EXHAUST VENT MATERIAL – USA

IBC strongly recommends only PPs or CPVC vent component systems approved

under ULC-S636 Standard for Type BH Gas Venting Systems, or stainless steel

Type BH venting systems* are to be used - BUT - many local jurisdictions in the

USA still allow the use of PVC (ULC-S636 or Sch. 40 ASTM D1785 or D2665

andttings)orCPVC(ULC-S636orSch.40/ASTMF441withSch.80ttings);

or CSA approved 3" stainless vent systems. If PVC is to be used, you shall use

a minimum of 10 lineal feet of CPVC, and then transition to PVC using approved

transition glue. The installer shall ensure that vent temperatures in the PVC

section cannot exceed 140°F.

Do not use ABS or any cellular core pipe for exhaust venting.

The boiler offers 2" venting connections. Fittings are to be used to adapt to

the appropriate diameter – see Vent Travel below. Exhaust venting is to be

connecteddirectlytothe2"NPTmalethreadedstainlesssteelttingonthe

bottom of the pressure vessel using:

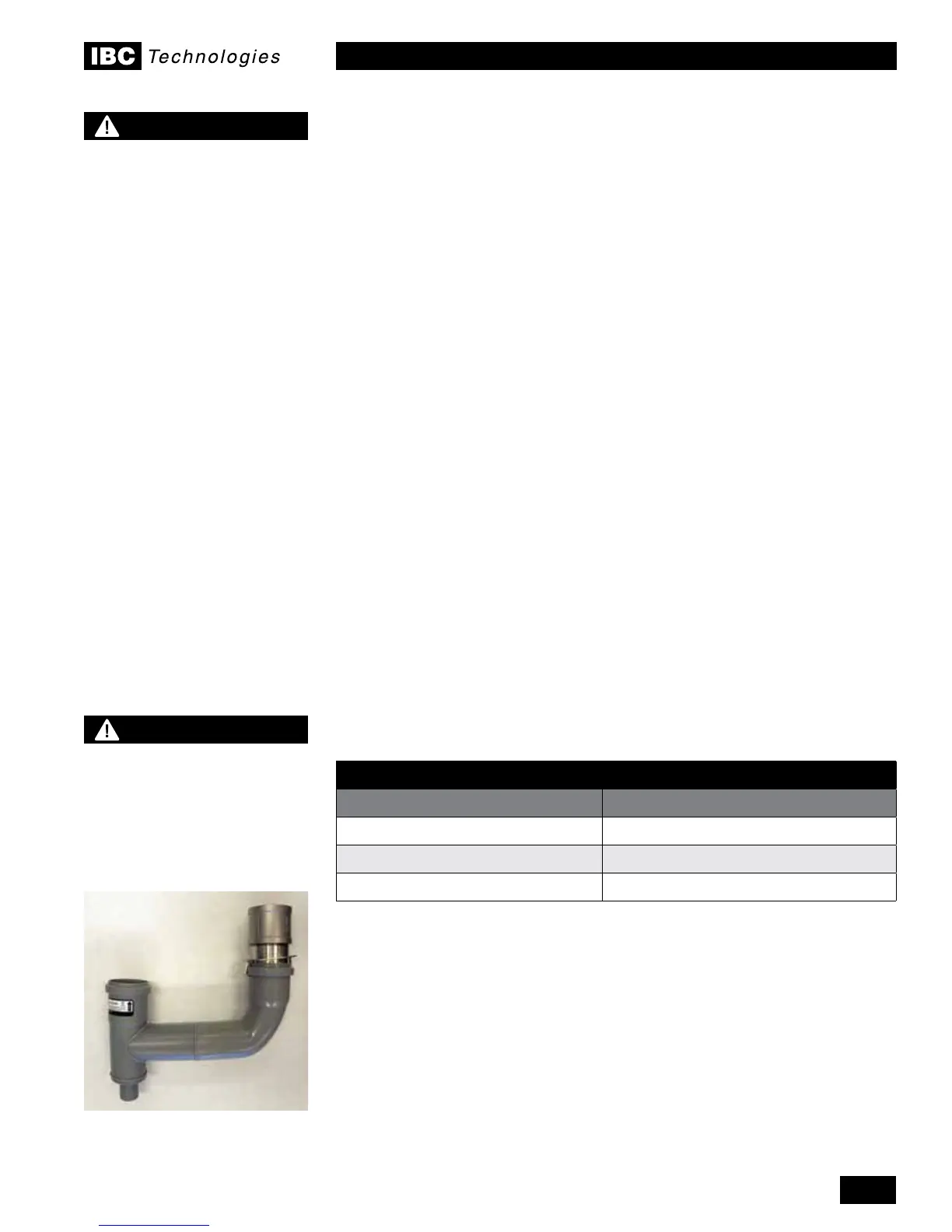

• For CPVC (and in the USA only, PVC) systems a 2" CPVC (USA: 2” PVC

allowed) threaded adaptor or 90° elbow adaptor. A condensate trap formed

usingthesuppliedttingsshallbeconsideredpartoftheexhaustandinstalled

near the base of the boiler (see Figure 2).

• for PPs, use IBC’s VFC PPs transition kit as appropriate for the chosen PPs

system:

CENTROTHERM INNOFLUE™ M&G DURAVENT POLYPRO™

KIT# P-166A KIT# P-167A

2” Stainless Coupler (190-044) 2” Stainless Coupler (190-044)

PPs Transition (180-037) PPs Transition (180-040)

Retainer Clip (180-050) Retainer Clip (180-051)

Combustion air piping is connected at the base of the boiler using a standard

2" PVC (ABS) coupler or elbow (see Section 1.4.7). For PPs intake piping, use

standard PPs : 2”Sch 40 adaptor parts from the respective PPs manufacturers.

Venting shall be supported in accordance with applicable code.

*Manufacturers of stainless steel Type BH venting systems must submit

their approved transition tting to IBC for evaluation and written approval.

DANGER

Failure to install PPs adaptor

with retainer clip could cause

release of harmful exhaust

gases into the heated space,

potentially leading to injury

or death.

WARNING

Do not mix PPs venting

materials from different

Manufacturers.

These venting materials are

designed to be installed as

part of a complete system.

Failure to comply may result

in severe personal injury or

death.

Figure 1c: PP Vent Adaptor

Assembly

Loading...

Loading...