1-11

INSTALLATION

VFC 15-150 - VFC 45-225 MODULATING GAS BOILERS

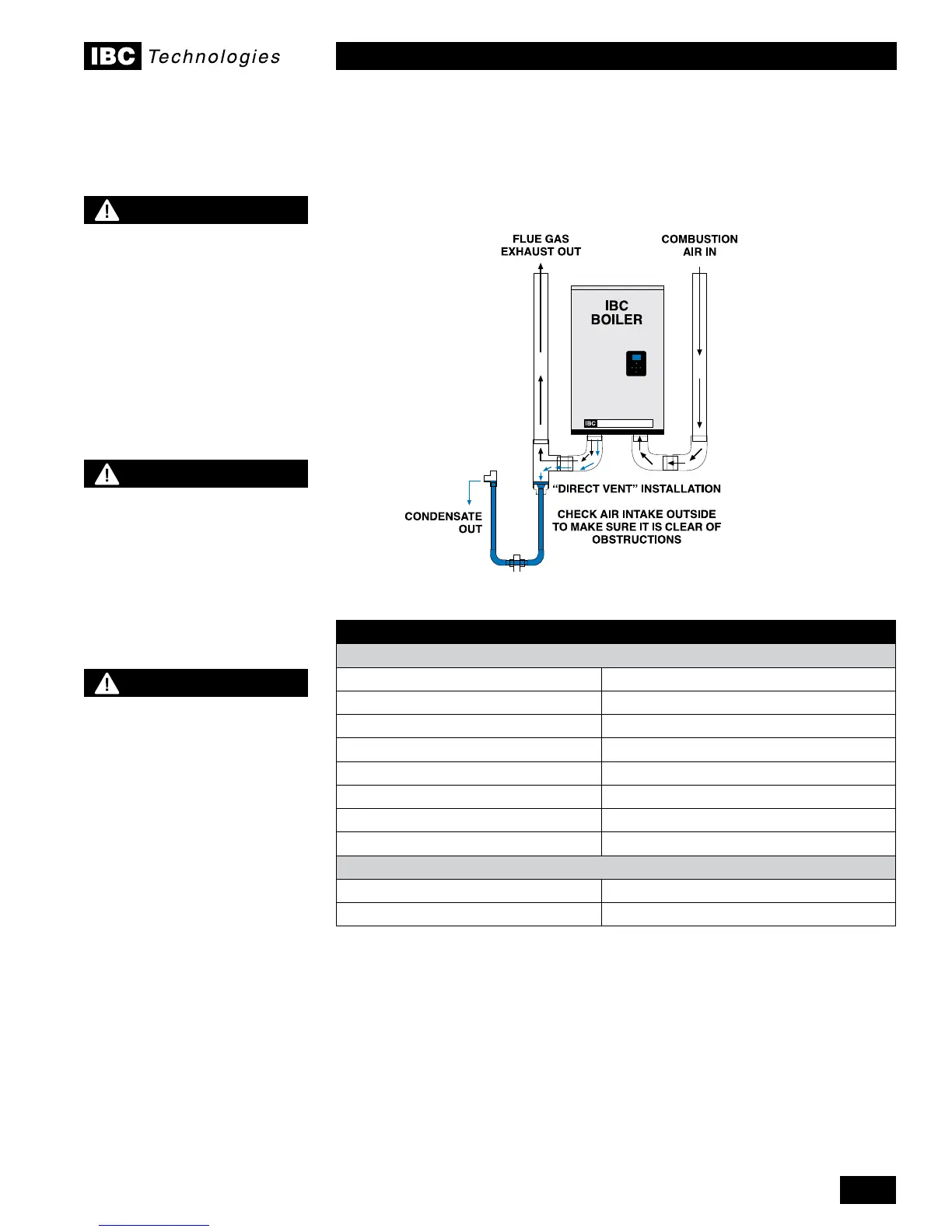

1.4.7 “Direct Vent” Combustion Air Intake Piping

There are two basic methods of supplying combustion air to an IBC boiler.

The direct vent option uses piping from the outside to supply combustion air

directly to the boiler’s combustion air connection.

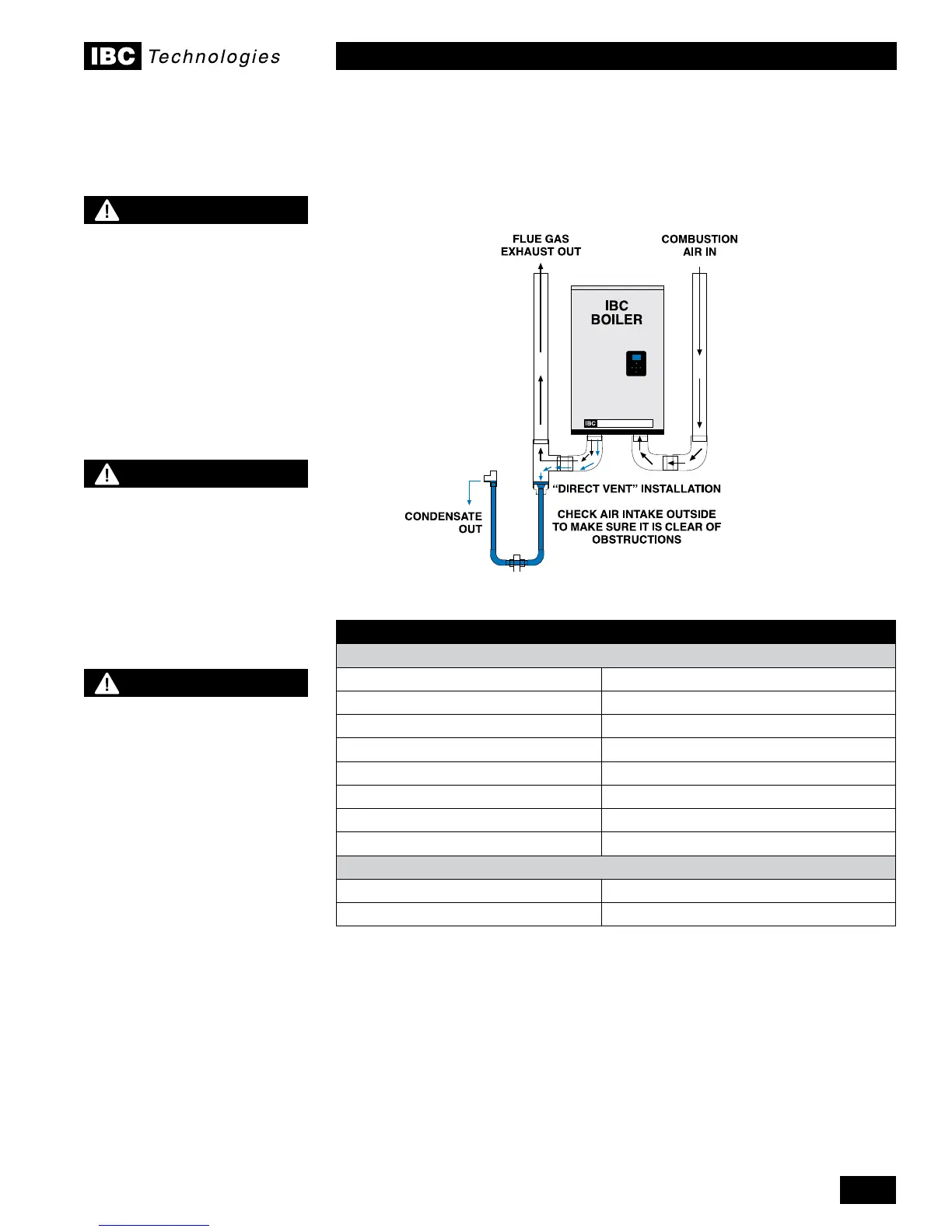

INTAKE PIPE SIZE MAXIMUM EQUIVALENT LENGTH

Sched.40; Rigid PPs

2" (15-150 only) 50' (each side)

2-1/2" (15-150 only) 70'

3" (15-150) 120'

3" (45-225) 240'

90° vent elbow allow 8' equivalent

45° elbow allow 3’ equivalent

PPs 87-90° elbow use 8’ equivalent

Air Intake Filter (Part #103) allow 8' equivalent

Flexible PPs

2” Flexible N/A

3” Flexible 60’ maximum (see Note 1)

Table 4: Maximum intake piping length

NOTE 1:

Further vent allowance is available for 3” Rigid Single Wall PPs as

follows: VFC 15-150: up to 30’ equivalent; VFC 45-225: up to 60’ equivalent.

For the inlet air – Schedule 40 PVC, ABS, or PPs piping of any type is permitted.

Use same diameter as Vent pipe, allowing for up to 6 ft actual run of 2” before

any required transition.

NOTE: It is not permitted to add to the exhaust length by transfer of unused

intake allowance.

WARNING

In addition to preventing

ingestion of chemical

contaminants, care must

be taken to ensure air

intake terminals are not

installed in locations where

contamination might occur

due to ingestion of particulate

foreign material (dust, dirt

and debris).

Figure 10: Direct vent - intake, exhaust and condensate removal system

NOTE

Care must be taken when

installing air intake piping to

ensure that a “trap” is not

formed in the piping so as to

allow a build-up of water, and

blockage of intake air.

Such blockage will result in a

boiler safety shut-down.

WARNING

Intake air openings must be

congured such that rain

or other forms of moisture

cannot enter the air intake

piping system. Otherwise

serious damage to the boiler

may result.

Loading...

Loading...