5

440 01 2021 01

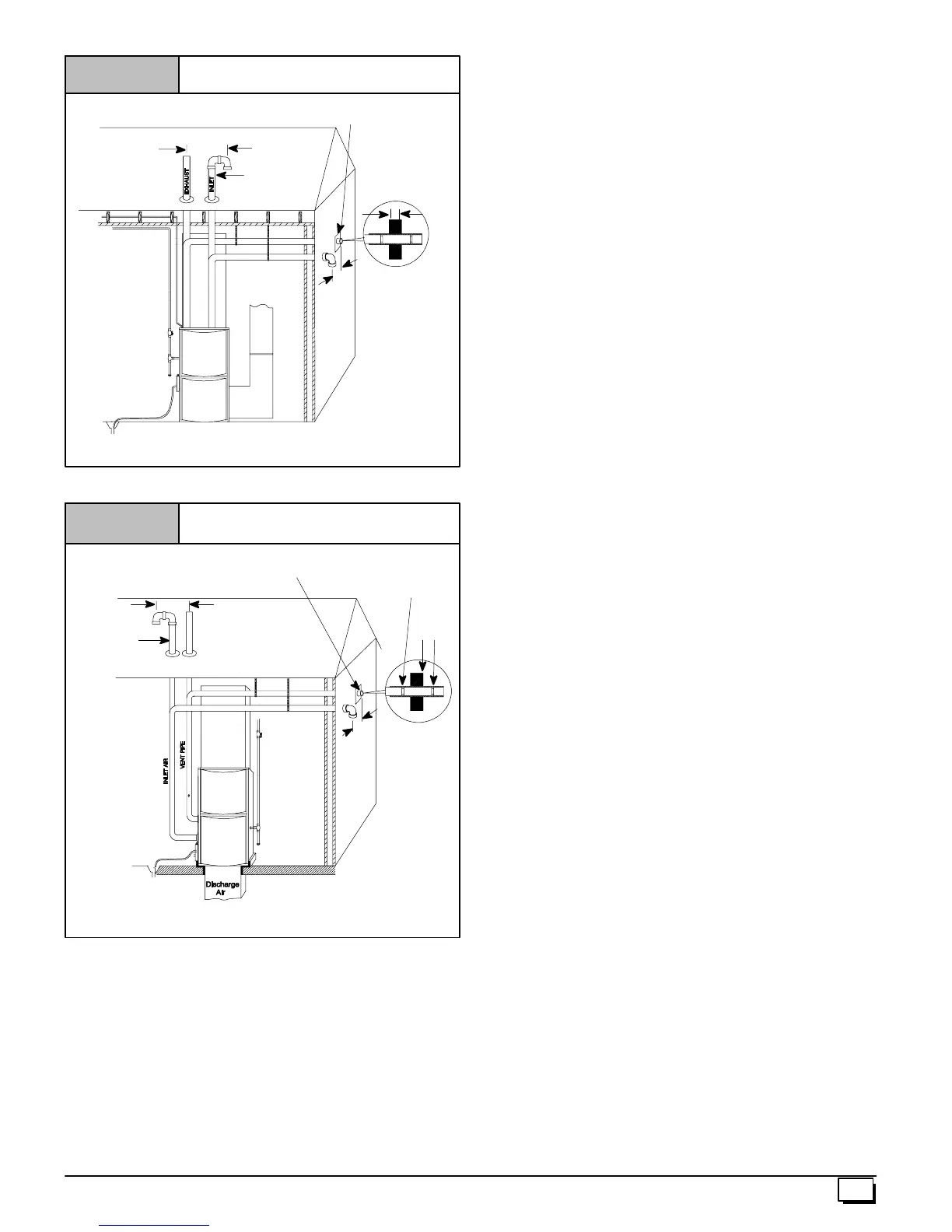

Vent Pipes MUST be

supported

Horizontally and

Vertically

*8² Min.

20¢ Max.

insameatmosphericzone

*8² Min.

20¢ Max.

in same

atmospheric

zone

Couplingon endsof

exhaust pipe. Total

pipe & coupling out-

side structure = 8²

Figure 1

Typical Upflow Installation

Aluminumor non-- rustingshield recommended.

(SeeVent TerminationShielding fordimensions).

*Increaseminimumfrom8²

²²

² to18²

²²

² forcoldclimates(sustainedtemperatures

below 0 °

°°

° F).

DISCHARGEAIR

25--23--33

InletPipe

(notused on

SinglePipe

model)

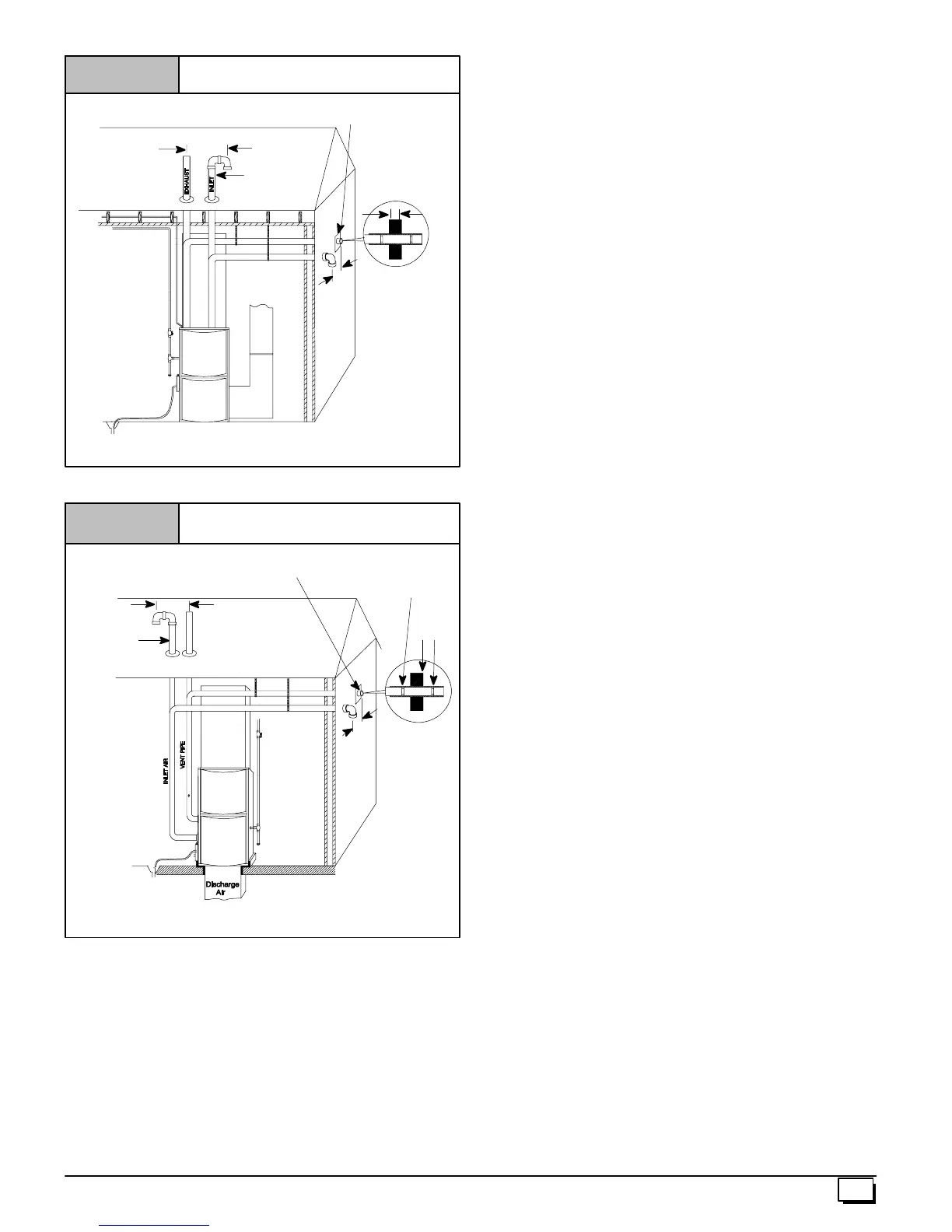

*8² Min.

20¢ Max.insame

atmosphericzone

Figure 2 Typical Downflow Installation

Vent Pipes MUST

besupportedHorizon-

tally and Vertically

* Increaseminimumfrom8²

²²

² to18²

²²

² forcoldclimates(sustainedtemperatures

below 0°

°°

°F).

See Vent Termination

Shielding inVentSection.

*8² Min.

20¢ Max.

in same

atmosphericzone

8² Min.

Coupling on inside

andoutsideofwallto

restrainvent pipe

25--23--33a

InletPipe

(notused on

SinglePipe

model)

Installation Requirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of build-

ings or structures under construction.

3. Install furnace as centralized as practical with respect to the

heat distribution system.

4. Install the vent pipes as short as practical, and in accor -

dance to these instructions. (See Vent and Combustion

Air Piping section).

5. Maintain clearance for fire safety and servicing. A front

clearance of 24² is required for access to the burner, con-

trols and filter. See clearance requirements in Figure 4.

6. Use a raised base for upflow furnace if the floor is damp or

wetattimes.

7. For downflow installations, non combustible subbase must

be used under the furnace unless installation is on a non

combustible floor surface. This requirement applies even

when a c oil box or cabinet is used.

8. For horizontal installations, line contact is permissible only

between lines formed by intersection of back and two sides

of furnace jacket, and building joists, studs or framing.

9. Residential garage installations require:

· Burners and ignition sources installed at least 18² above

the floor.

· Located or physically protected from possible damage by

a vehicle.

10. Local codes may require a drain pan under the entire fur-

nace and condensate trap when the furnace is installed in

attic application.

This furnace may be used for construction heat provided that all

the following conditions are met:

· The furnace is permanently installed with all electrical wir-

ing, piping, venting and ducting installed according to these

installation instructions. A return air duct is provided, sealed

to the furnace casing, and terminated outside the s pace

containing the furnace. This prevents a negative pressure

condition as created by the circulating air blower, causing a

flame rollout and/or drawing c ombustion products into the

structure.

· The furnace is controlled by a thermostat. It may not be “hot

wired” to provide heat continuously to the structure without

thermostatic control.

· Clean outside air is provided for combustion. This is to mini-

mize the corrosive effects of adhesives, sealers and other

construction materials. It also prevents the entrainment of

drywall dust into combustion air, which can cause fouling

and plugging of furnace components.

· The temperature of the return air to the furnace is main-

tained between 55° F(13° C) and 80° F(27° C) , with no eve-

ning setback or shutdown. The use of the furnace while the

structure is under construction is deemed to be intermittent

operation per our installation instructions.

· The air temperature rise is within the rated rise range on the

furnace rating plate, and the firing rate has been set to the

rating plate value.

· The filters used to clean the circulating air during the

construction process must be either changed or thoroughly

cleaned prior to occupancy.

· The furnace, ductwork and filters are cleaned as necessary

to remove drywall dust and construction debris from all

HVAC system components after construction is completed.

· After c onstruction is complete, verify furnace operating con-

ditions including ignition, input rate, temperature rise and

venting according to these instructions.

Loading...

Loading...