18

441 01 2611 06

Exterior Masonry Chimney,

FAN+NAT Installations with

Type--B Double--Wall Vent Connectors

ã

ãã

ã NFPA&AGA

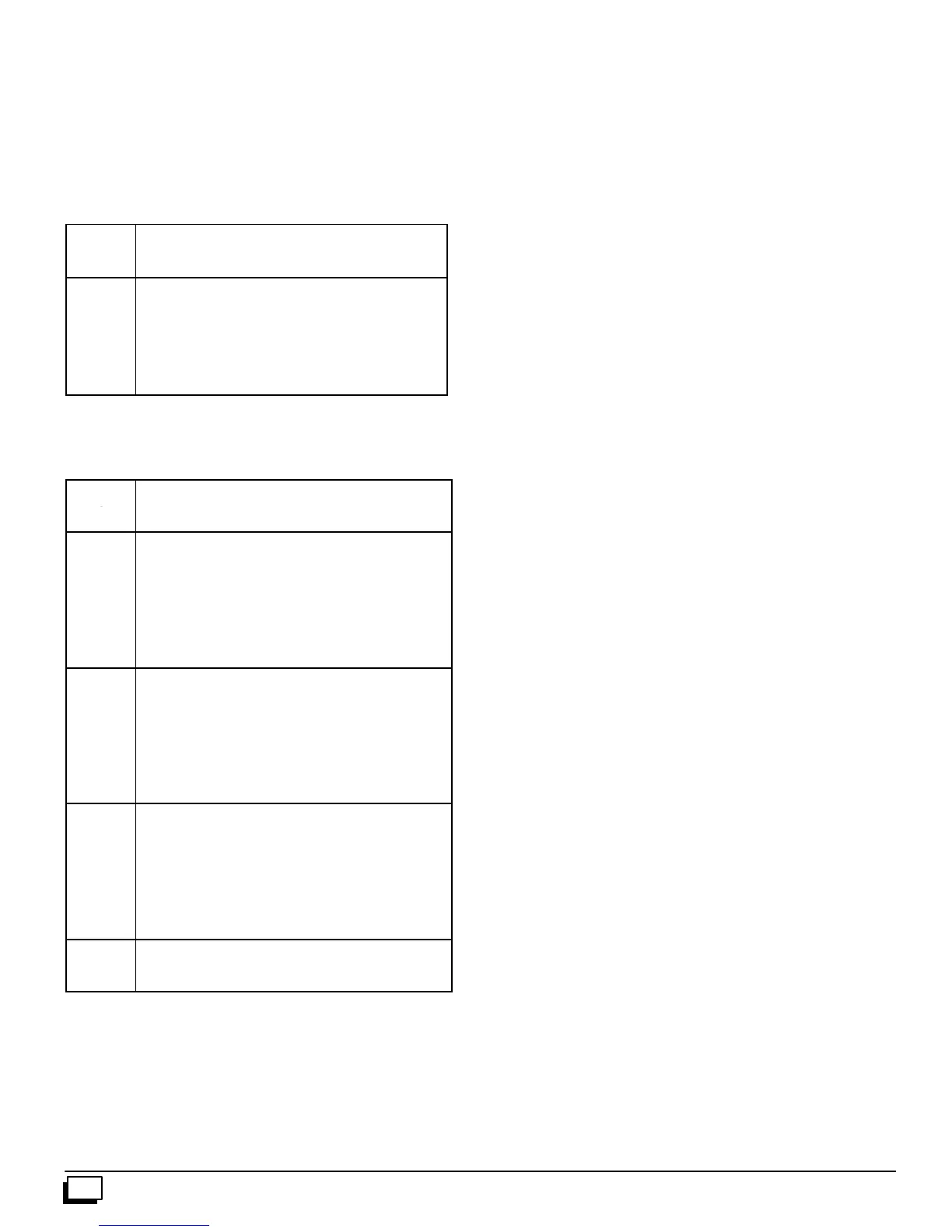

Table A--

Combined Appliance

Maximum Input Rating in

Thousands of Btu per Hr

VENT

HEIGHT

INTERNAL AREA OF CHIMNEY

(SQ IN.)

(FT)

12 19 28 38

6 74 119 178 257

8 80 130 193 279

10 84 138 207 299

15 NR 152 233 334

20 NR NR 250 368

30 NR NR NR 404

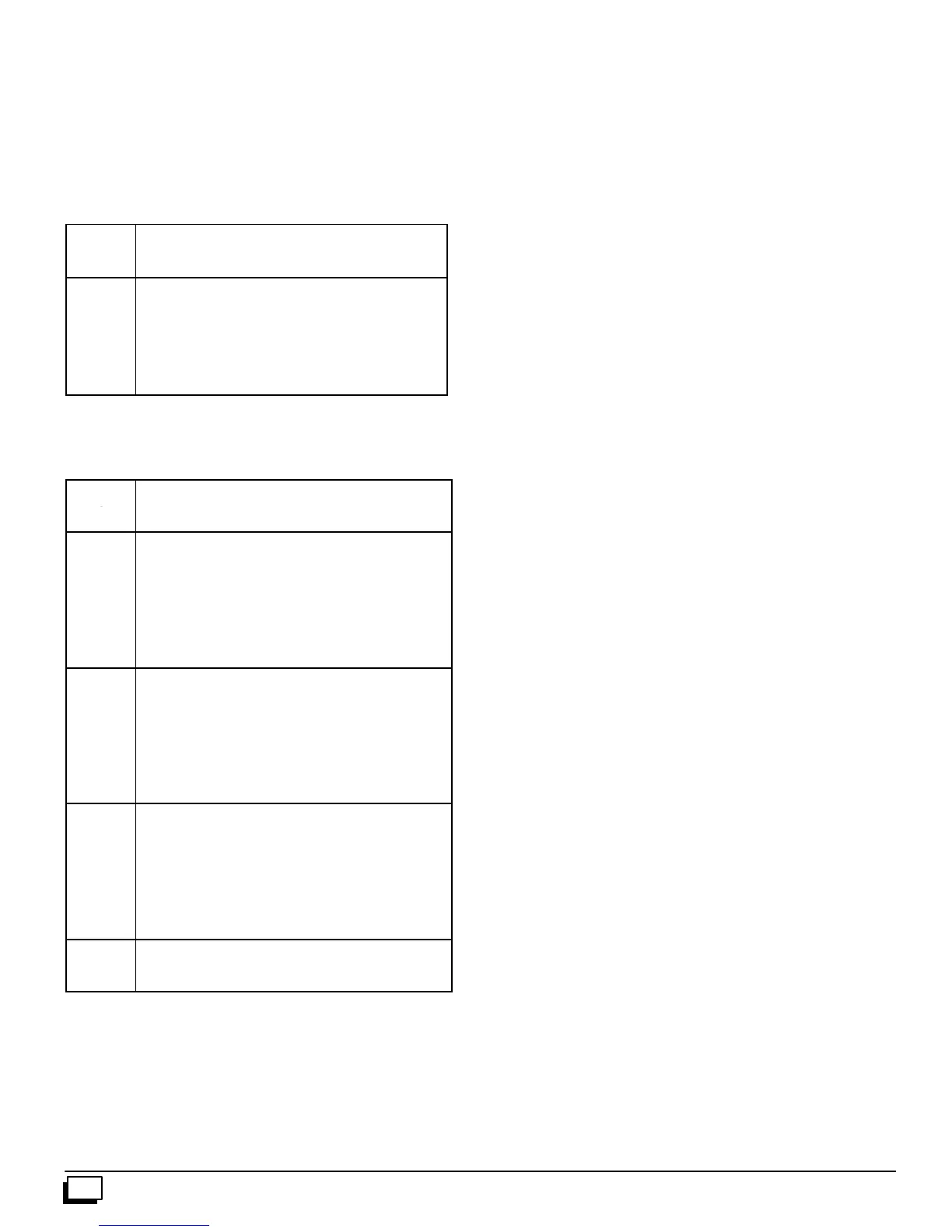

Table B--

Minimum Allowable Input Rating of

Space--Heating Appliance in

Thousands of Btu per Hr

VENT

HEIGHT

INTERNAL AREA OF CHIMNEY

(SQ IN.)

(FT)

12 19 28 38

Local 99% Winter Design Temperature: 17 to 26°

°°

° F*

6 0 55 99 141

6

°

°

°

°F

8 52 74 111 154

o2

10 NR 90 125 169

7t

15 NR NR 167 212

1

20 NR NR 212 258

30 NR NR NR 362

Local 99% Winter Design Temperature: 5 to 16°

°°

° F*

6 NR 78 121 166

°

°

°

°F

8 NR 94 135 182

16

10 NR 111 149 198

5t

15 NR NR 193 247

20 NR NR NR 293

30 NR NR NR 377

Local 99% Winter Design Temperature: --10 to 4°

°°

° F*

6 NR NR 145 196

4

°

°

°

°F

8 NR NR 159 213

to

10 NR NR 175 231

10

15 NR NR NR 283

--

20 NR NR NR 333

30 NR NR NR NR

-- 11 °

°°

° F

or

Local 99% Winter Design Temperature: --11°

°°

° For

lower*

lower

Not recommended for any vent configuration

* The 99% Winter Design Dry--Bulb (db) temperatures are found in the

1993 ASHRAE Fundamentals Handbook, Chapter 24, Table 1

(United States) and 2 (Canada), or use the 99.6% heating db

temperaturesfound in the 1997 or 2001 ASHRAE Fundamentals

Handbook, Climatic Design Information chapter, Table 1A (United

States) and 2A (Canada).

Inspectionsbeforethesaleandatthetimeofinstallationwilldeter-

minetheacceptabilityofthechimney ortheneedforrepairand/or

(re)lining. Refer to the Chimney Inspection Chart to perform a

chimney inspection.

If the inspection of a previously used tile--lined chimney:

a. Showssignsofventgas condensation,the chimneyshould

be relined in accordance withlocal codes and theauthority

having jurisdiction. The chimney should be relined with a

listed metal liner, Type--B vent, or a listed chimney adapter

kittoreducecondensation. Ifacondensatedrainisrequired

bylocalcode,refertotheNFGC,Section10.9foradditional

information on condensate drains.

b. Indicates the chimney exceeds the maximum permissible

sizeinthetables,thechimneyshouldberebuiltorrelinedto

conform to the requirements of the equipment being

installed and the authority having jurisdiction.

Achimneywithouta c lay tileliner, whichis otherwiseingoodcon-

dition,shallberebuilttoconformtoANSI/NFPA211orbelinedwith

a UL listed (ULClisted in Canada)metalliner or UL listed Type--B

vent. Relining with a listed metal liner or Type--B vent is consid-

ered to be a vent--in--a--chase.

If a metal liner or Type--B vent is used to line a chimney, no other

appliance shall be vented into the annular s pace between the

chimney and the metal liner.

APPLIANCE APPLICATION REQUIREMENTS

Appliance operation has a significant impact on the performance

of the venting system. If the appliances are sized, installed, ad-

justed, and operated properly, the venting system and/or the ap-

pliances should not sufferfrom condensation and corrosion. The

ventingsystemandallappliancesshallbeinstalledinaccordance

with applicable listings, standards, and codes.

The furnace should be sized to provide 100 percentof the design

heating load requirementplus any margin that occurs because of

furnace model size capacity increments. Heating load estimates

can be made using approved methods available from Air Condi-

tioning Contractors of America (Manual J); American Society of

Heating, Refrigerating, and Air--Conditioning Engineers; or other

approved engineering methods. Excessive oversizing of the fur-

nace could cause the furnace and/or vent to fail prematurely.

Whenametalventormetallinerisused,thev entorlinermustbein

goodconditionandbeinstalledinaccordancewiththeventorliner

manufacturer’s instructions.

To prevent condensation in the furnace and vent system, the fol-

lowing precautions must be observed:

1. Thereturn--airtemperaturemustbeatleast60°Fdbexcept

forbriefperiodsoftimeduringwarm--up fromsetback at no

lower than 55°F db or during initial start--up from a standby

condition.

2. Adjust the gas input rate per the installation instructions.

Lowgasinputratecauseslowventgastemperatures,caus-

ing condensation and corrosion in the furnace and/or vent-

ing system. Derating is permitted only for altitudes above

2000¢.

3. Adjust the air temperature rise to the midpoint of the rise

rangeorslightlyabove. Lowairtemperaturerisecancause

low vent gas temperature and potential for condensation

problems.

4. Set the thermostat heat anticipator or cycle rate to reduce

short cycling.

Air for combustion must not be contaminated by halogen com-

poundswhichincludechlorides,fluorides,bromides,andiodides.

These compounds are found in many common home products

suchasdetergent,paint,glue,aerosolspray,bleach,cleaningsol-

vent,salt, and airfreshener, and can cause corrosion of furnaces

and vents. Avoidusing such products in the combustion--air sup -

ply. Furnace use during construction of the building could cause

thefurnacetobeexposedtohalogencompounds,c ausingprema-

ture failure of the furnace or venting system due to corrosion.

Loading...

Loading...