23

441 01 2611 06

Fan Control

ThefancontrolispresetatthefactorywithONdelayof30seconds

in the heating mode. The blower OFF timing is preset at 140sec-

onds. If desired,the fan OFF delay can bereset to obtain thelon-

gest delay times while still maintaining comfort levels. See

“Furnace Wiring Diagram”.

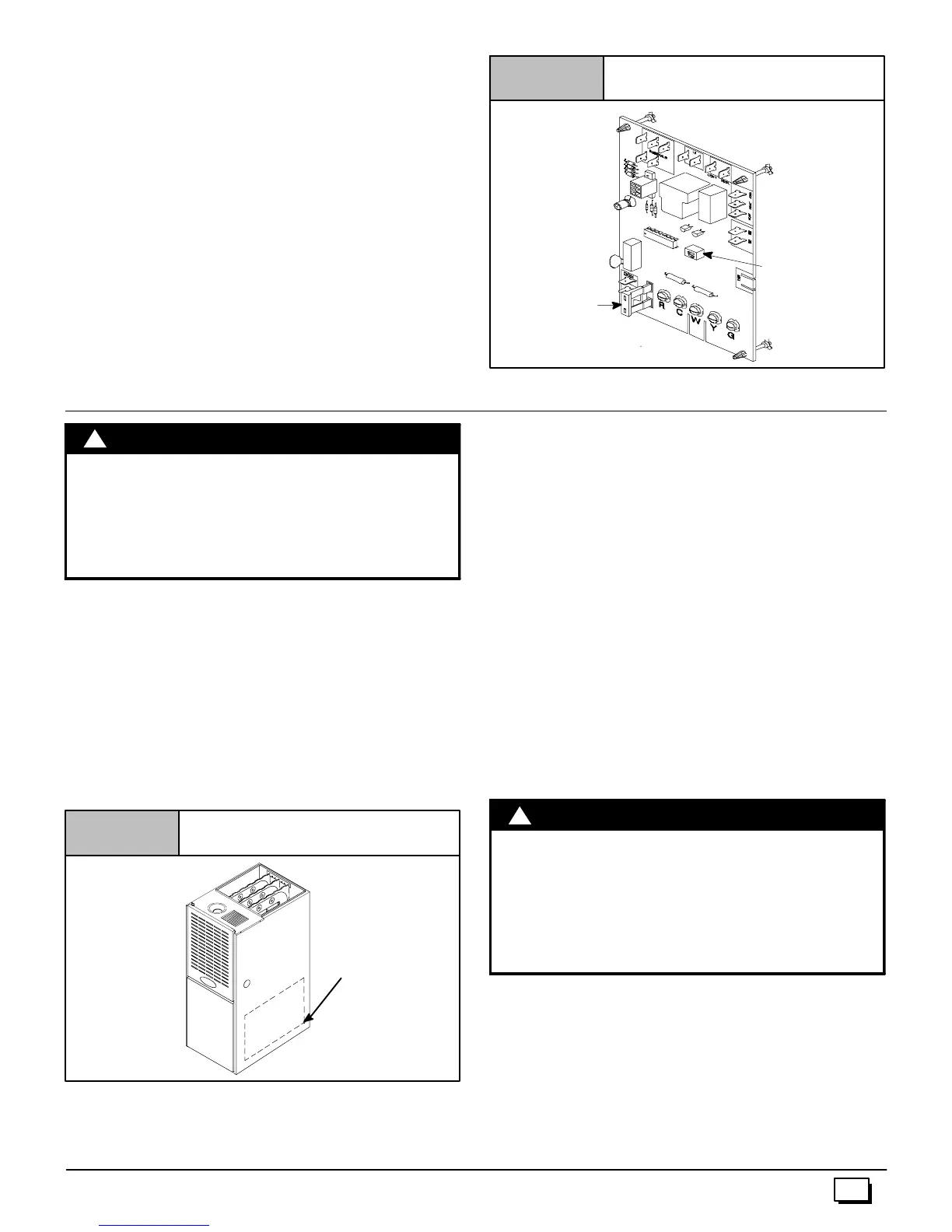

Control Center Fuse

The 24V circuit contains a 5--amp, automotive--type fuse located

oncontrolcenter.(SeeFigure 20 )Anyelectricalshortsof24Vwir-

ingduring installation,service,ormaintenancemaycausefuseto

blow. If fuse replacement is required, use only a fuse of identical

size (5 amp.).

Fan Timer Connections

Figure 20

DIP Switch

FUSE

25--23--41

10. Ductwork and Filter (Upflow/Horizontal)

CARBON MONOXIDE POISONING HAZARD.

Failure to properly seal duct could result in death

and/or personal injury.

DoNOT draw returnair from inside a closet or utility

room where furnace is located. Return air duct

MUST be sealed to furnace casing.

!

WARNING

Duct Connections

This furnace may be installed in only a bottom or side return--air

duct application. Return air duct connections through the back of

the furnace is NOT permitted.

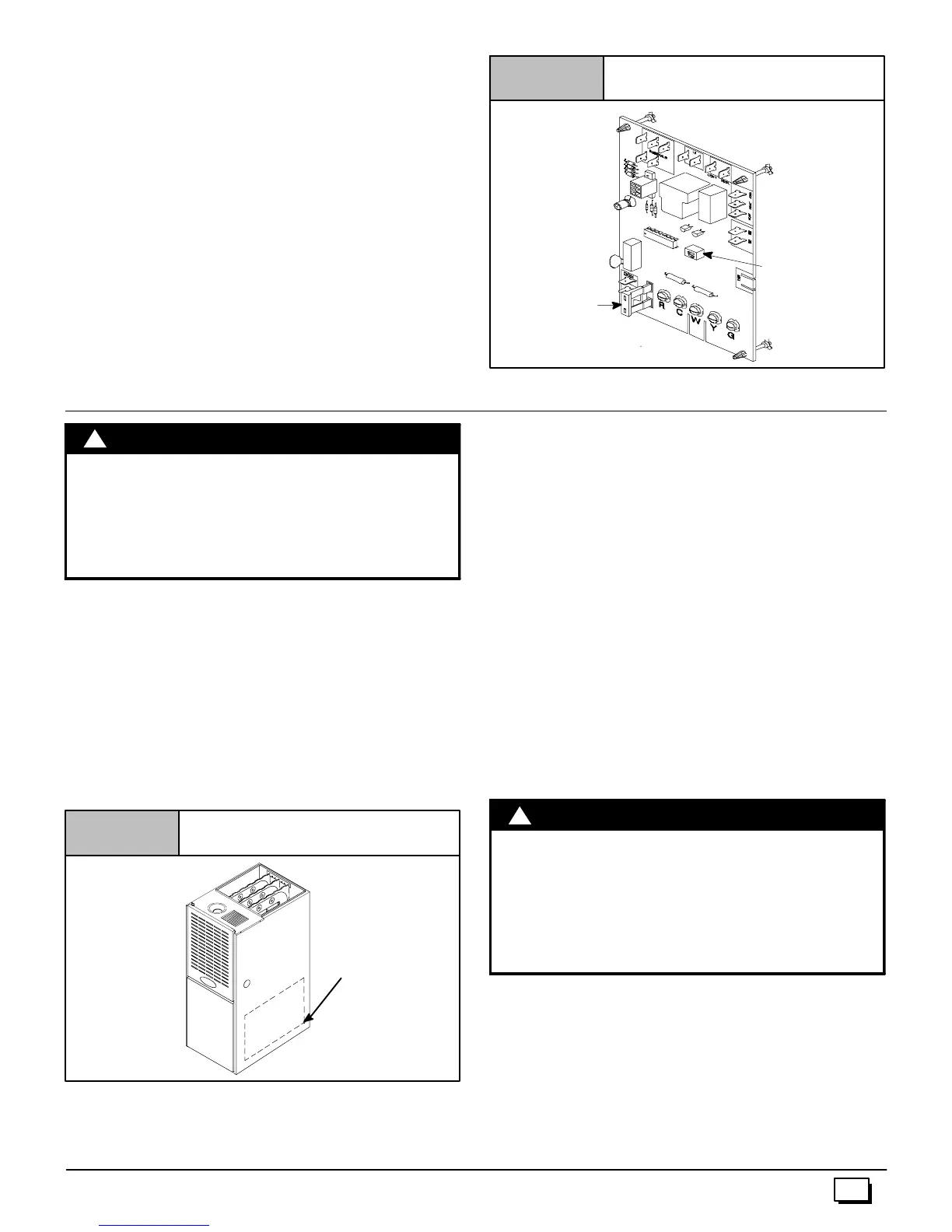

Upflow ONLY: Side return--air duct connections can be made by

cutting out the embossed area shown in Figure 21. A plugged

holeisprovidedateachfurnacesideductlocationtohelpstartcut-

tingtheopening. Sideductc onnectionsareNOTpermittedinhori-

zontal flow applications.

Cutting Side Return Air Opening

Figure 21

Plugged

Starting

Hole

Upflow and Horizontal Flow: Bottom return--air duct connec-

tions can be made by removing the knockout panel in thefurnace

base. Do NOT remove knock-out except for a bottom return--air

duct connection.

Duct Design

Designandinstallairdistributionsystemto complywithAirCondi-

tioning Contractors of America manuals or other approved meth-

ods that conform to local codes and good trade practices.

Whenthefurnaceislocatedinanareanearoradjacenttotheliving

area,thesystemshouldbecarefullydesignedwithreturnstomini-

mize noise transmission through the return air grille. Any blower

movingahighvolumeofairwillproduceaudiblenoise,whichcould

beobjectionablewhenthefurnaceislocatedvery closetoaliving

area. It is often advisable to route the return air ducts under the

floor or through the attic.

· Refer to furnace Technical Support Manual (Blower Data)

for air flow information.

· Sizeductworktohandleairflowforheating(andaircondition-

ing if so equipped).

Duct Installation Requirements

· When a furnace is installed so that supply ducts carry aircir-

culated by the furnace to areas outside of the space contain-

ingthefurnace,thereturnairshallalsobehandledby duct(s)

sealed to the furnace casing and terminating outside the

space containing the furnace.

CARBON MONOXIDE POISONING HAZARD.

Failure to follow safety warning exactly could

result in serious injury, d eath, and/or property

damage.

Install cooling coil on furnace discharge. Cool air

passing over heat exchanger could cause conden-

sate to form resulting in heat exchanger failure.

!

W

RNING

· Whenthefurnaceisusedwithacoolingunit,thefurnaceshall

beinstalledparallelwithorontheupstreamsideofthecooling

unit to avoid condensation in the heating element.

· Withaparallelflowarrangement,thedampersorothermeans

usedto controlflowofair shallbeadequatetopreventchilled

airfromenteringthefurnace.Chilledairgoingthroughthefur -

nace could cause condensation and shorten furnace life.

Dampers (purchased locally) can be either automatic or

manual. Manuallyorautomatically operateddampersMUST

be equipped with a means to prevent furnace and air condi-

tioningoperation,unlessdamperisinthefullheatorcoolposi-

tion.

Loading...

Loading...