19

441 01 2611 06

Vent dampers on any appliance connected to the common vent

cancausecondensationandcorrosion in the ventingsystem. Do

notuseventdampersonappliancescommonventedwiththisfur-

nace.

8. Gas Supply and Piping

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to follow safety warnings exactly could

result in serious injury, death, and/or property

damage.

Models designated for Natural Gas are to be used

withNaturalGasONLY,unlessproperlyconvertedto

use with LP gas.

!

WARNING

Gas Supply Requirements

· UseonlytheTypeofgasapprovedforthisfurnace.Seerating

plate for approved gas type.

· Gasinputmustnotexceedtheratedinputshownontherating

plate. Overfiring will result in failure of heat exchanger and

cause dangerous operation.

· Donotallowminimumsupplypressuretovarydownward.Do-

ingso will decrease inputto furnace. Refer to Table 3 forgas

supply. Refer to Table 7 and Table 8 for manifoldpressures.

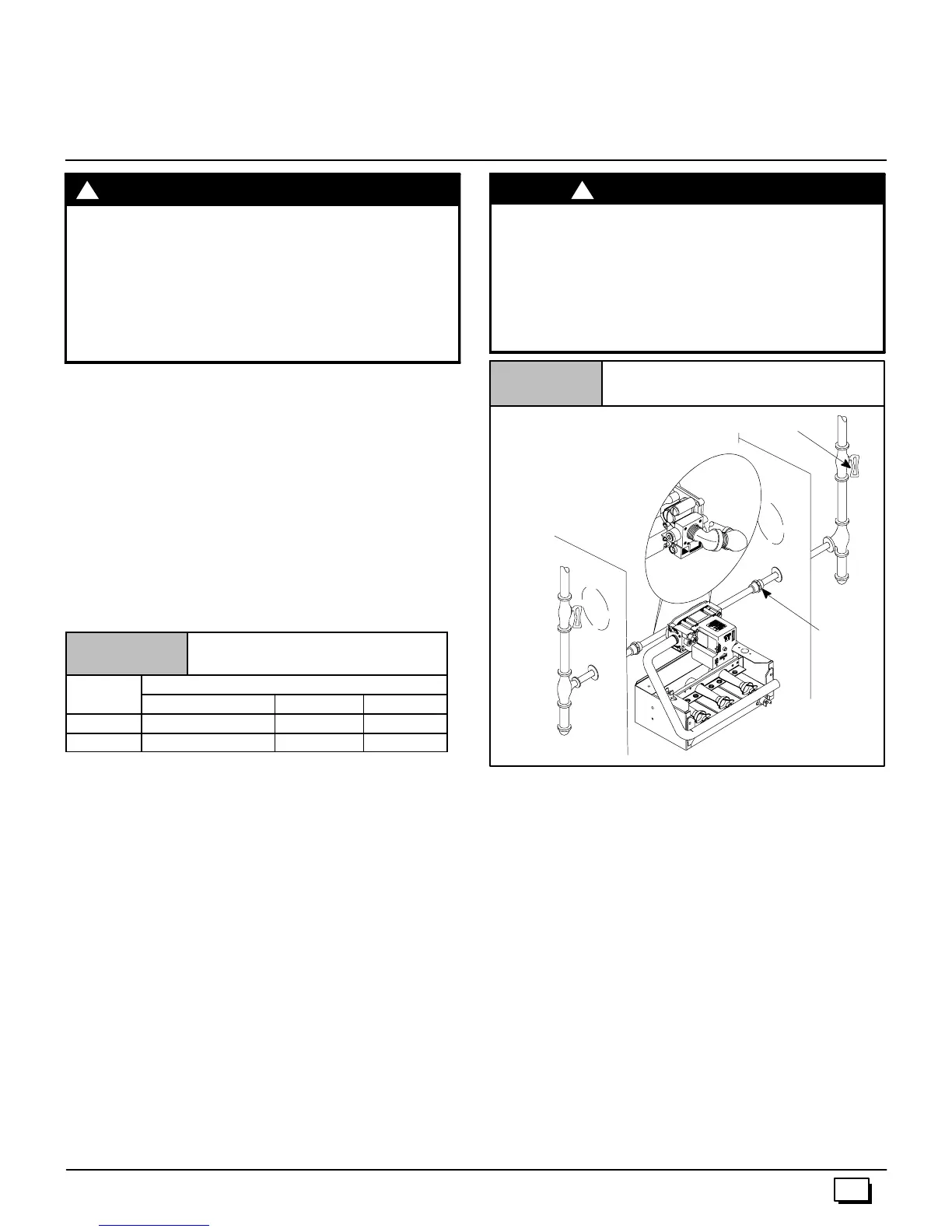

Table 3 Gas Pressures

Supply Pressure

as

ype

Recommended Max. Min.

Natural 7² 14² 4.5²

Propane 11² 14² 11²

Gas Piping Requirements

NOTE:Thegassupplylinemustbeinstalledbyaqualifiedservice

technician in accordance with all building c odes.

NOTE: In the state of Massachusetts.

a. Gas supply connections MUST be performed by a li -

censed plumber or gas fitter).

b. Whenflexibleconnectorsareused,themaximumlength

shall not exceed 36² (915 mm).

c. When lever handle type manual equipment shutoff

valves are used, they shall be T--handle valves.

d. TheuseofcoppertubingforgaspipingisNOTapproved.

1. Installgas pipinginaccordancewithlocalcodes,orintheab-

sence of local codes, the applicable national codes.

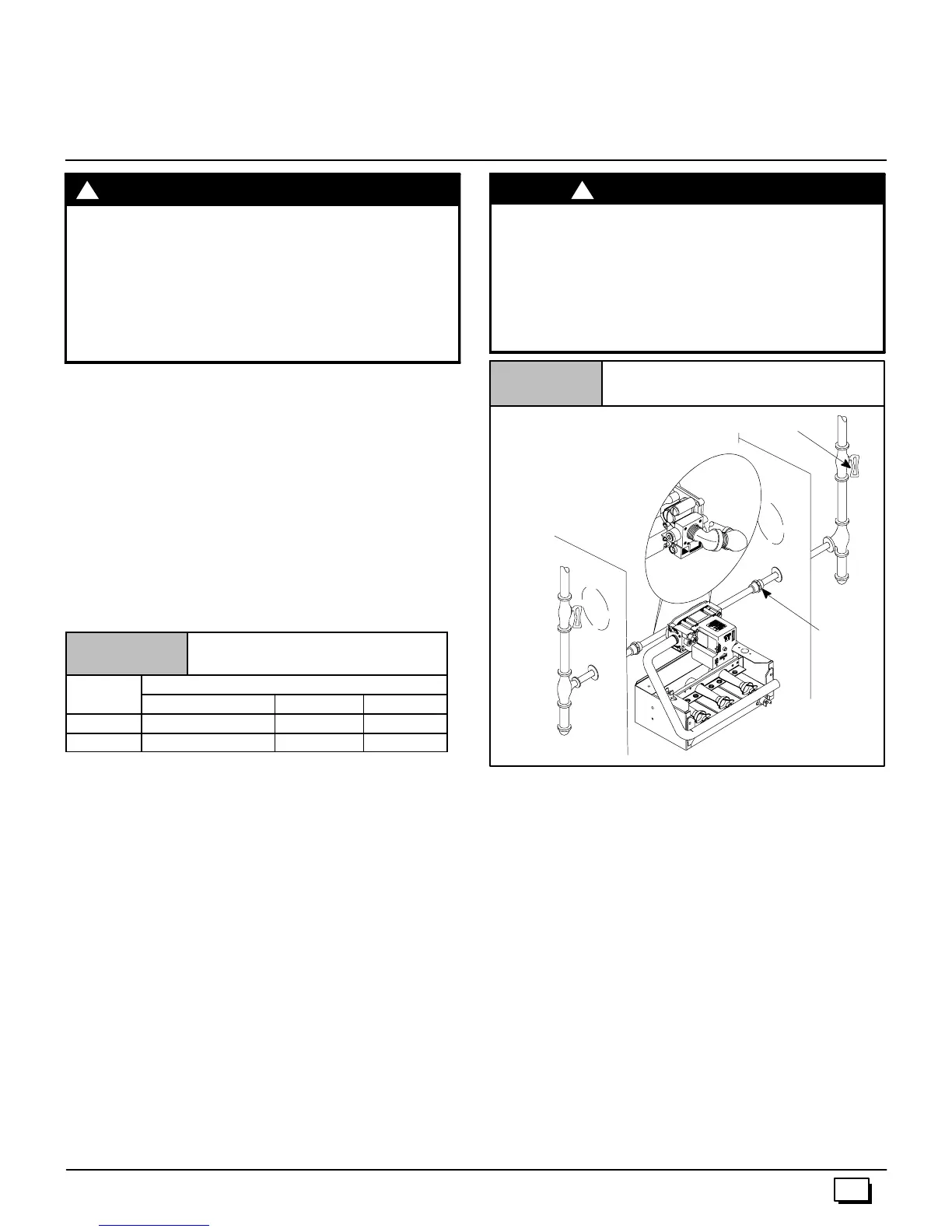

2. Itis recommendedthata manual equipment shutoff valve be

installed in the gas supply line outside the furnace. Locate

valveasclosetothefurnaceaspossiblewhereitisreadilyac-

cessible. Refer to Figure 12.

FIRE HAZARD

Failure to follow safety warnings exactly could

result in serious injury, death, and/or property

damage.

Use wrench to hold furnace gas control valve when

turning elbows and gas line to prevent damage to

the gas control valve and furnace.

!

W

RNING

Typical Gas Piping (N8MP)

Figure 12

Left entry

Right entry

Dipleg&pipecap

Left side entry

Union

Manual Equipment Shutoff Valve

25--24--36

3. Useblackironorsteelpipeandfittingsorotherpipeapproved

by local code.

4. Use pipe thread compound which is resistant to natural and

LP gases.

5. Use ground joint unions and install a drip leg no less than 3²

long to trap dirt and moisture before it can enter gas control

valve inside furnace.

6. Providea

1

/

8

² NPTpluggedtappingfortestgaugeconnection

immediately up stream of gas supply connection to furnace.

7. Usetwopipe wrencheswhenmaking connections toprevent

furnace gas control valve from turning.

NOTE:Iflocalcodesallowtheuseofaflexiblegasappliancecon-

nector,alwaysuseanewlistedconnector. Donotuseac onnector

which has previously served another gas appliance.

8. Flexible corrugated metal gas connector may NOT be used

inside the furnace or be s ecured or supported by the furnace

or ductwork.

9. Properly size gas pipe to handle combined appliance load or

run gas pipe directly from gas meter or LP gas regulator.

10. Install correct pipe size for run length and furnace rating.

11. MeasurepipelengthfromgasmeterorLPsecondstageregu-

lator to determine gas pipe size.

Loading...

Loading...