24

441 01 2611 06

· Installation of locking-type dampers is recommended in all

branches,orinindividualducts tobalancesystem’sairflows.

· Non--combustible, flexible duct connectors are recom-

mended for return and supply connections to furnace.

· Ifairreturngrilleislocatedclosetothefaninlet,installatleast

one 90° air turn between fan and inlet grille to reduce noise.

· Ductworkinstalledinatticorexposedtooutsidetemperatures

requiresaminimumof2² ofinsulationwithoutdoortypevapor

barrier.

· Ductworkinstalledinanindoorunconditionedspacerequires

a minimum of 1 ² of insulation with indoor type vapor barrier.

Inspection Panel on some models

Forafurnacenotequippedwithacoolingc oil,theoutletductshall

beprovidedwitharemovableaccesspanel. Thisopeningshallbe

accessiblewhenthefurnaceisinstalledandshallbeofs uchasize

thattheheatexchangercanbeviewedforpossibleopeningsusing

light assistance or a probe can be inserted for sampling the air

stream. This access cover shall be attached in such a manner as

to prevent air leaks.

Filters

A filter MUST be used.

Filtersarenotsupplied

withthesefurnaces,butcanbepurchased

from your distributor.

See Table 4 for required high--velocity filter sizes.

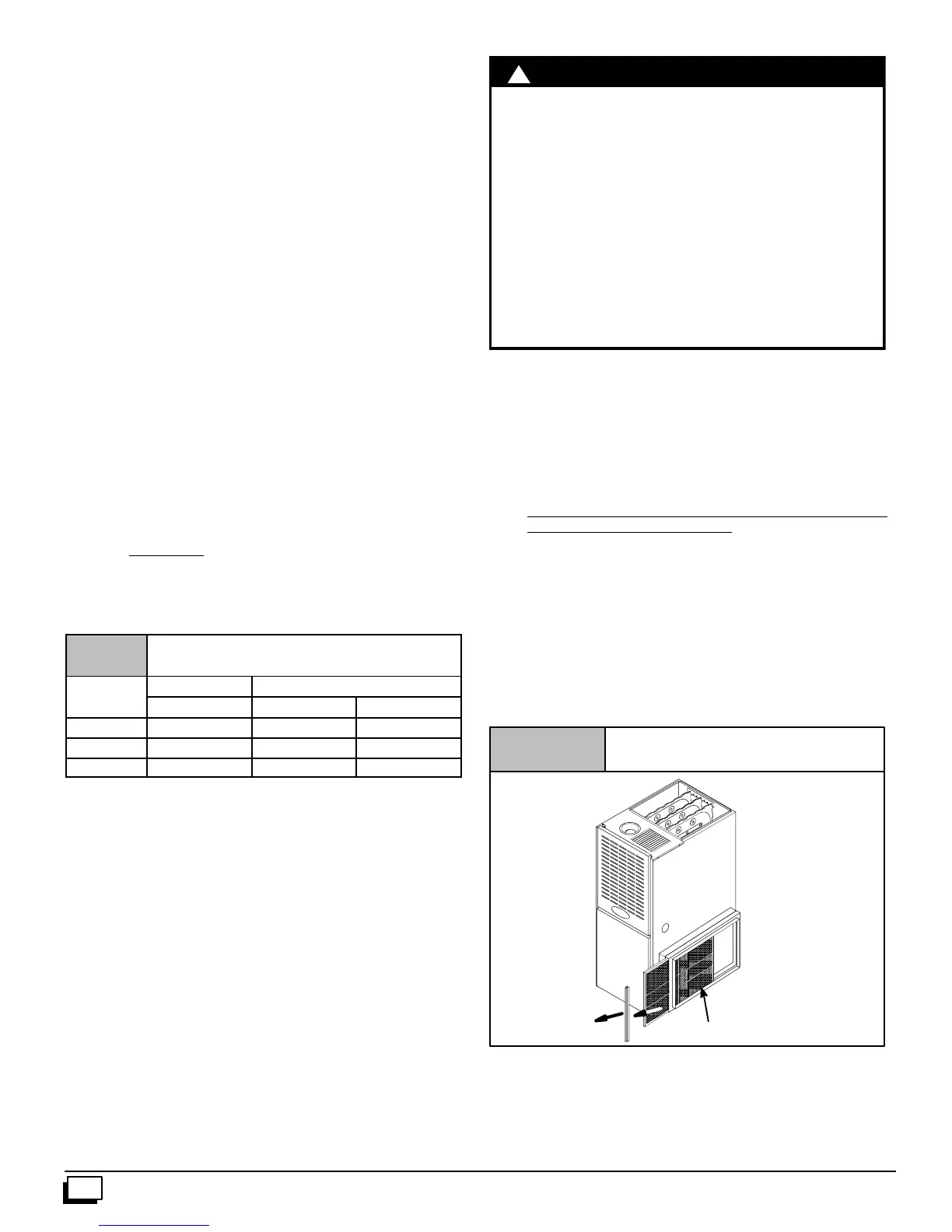

Table 4

High--Velocity Air Filter Sizes (max.600 FPM)

Cabinet

Internal Filter External Filter Rack

Width

Bottom Bottom Side+

15

1

/

2

14X25 14X25 14X25 or 16X25

19

1

/

2

16X25* 16X25* 16X25*

22

3

/

4

20X25* 20X25* 16X25*

* Greater than 1600 CFM requires both (left and right) side return filter

racks in upflow position.

+Sidereturnairduct(s)isnotpermittedwithhorizontalordownflowfurnace

installation.

Use either filter type:

· Washable,high--velocityfiltersarebasedonamaximumair

flow rating of 600 FPM.

· Disposable,lowvelocityfiltersarebasedonamaximumair

flow of 300 FPM when used with external filter grille.

!

RISK OF REDUCED FURNACE LIFE

Failure to follow these Caution may result in

premature furnace component failure.

Use of excessively dirty and/or restrictive air filters

may increase furnace operating temperatures and

shorten the life of the furnace.

Filters specified for the furnace are rated at a maximum

of 600 FPM air velocity and sized for the furnace’s

airflow rate. Replacement filters must be of equivalent

type, size, and rating except as described below.

Disposable, low--velocity filters may be used to replace

washable, high--velocity filters, providing they are sized

for 300 FPM or less.

C

UTION

· The furnaces with 1600 or less CFM rating use a 16” x 25”

high--velocity filter. On these models the filter may be

mountedinternallyforbottomreturn ora filter and rackmay

be mounted externally for bottom return.

· The furnaces withgreater than 1600 CFM require that both

(left and right) side returns are used. Two side return filters

andracksarerequired.Filterracks mustbemountedexter-

nally. See Figure 24.

· If return air must be on one side only, an optional 20² x25²

filterstandoffrackkitcanbeused.(SeeFigure 22.)Forbot-

tomreturn,aninternalfiltercanbeusedorafilterrackkitcan

be mounted externally.

NOTE:The20 ² x25² standoffs idefilterrackgivesmorefilterarea

but does not provide more air. See Figure 22. To achieve 2000

CFM 2 side returns are still needed. See Figure 24.

NOTE: Disposable low--velocity filters may be replaced with

washable,high--velocityfilters.Washable,high--velocityfilterscan

bereplacedONLYwithsametypeandsizefilterunlesslow--veloc-

ity filters meet the minimum size areas for 300 FPM or less.

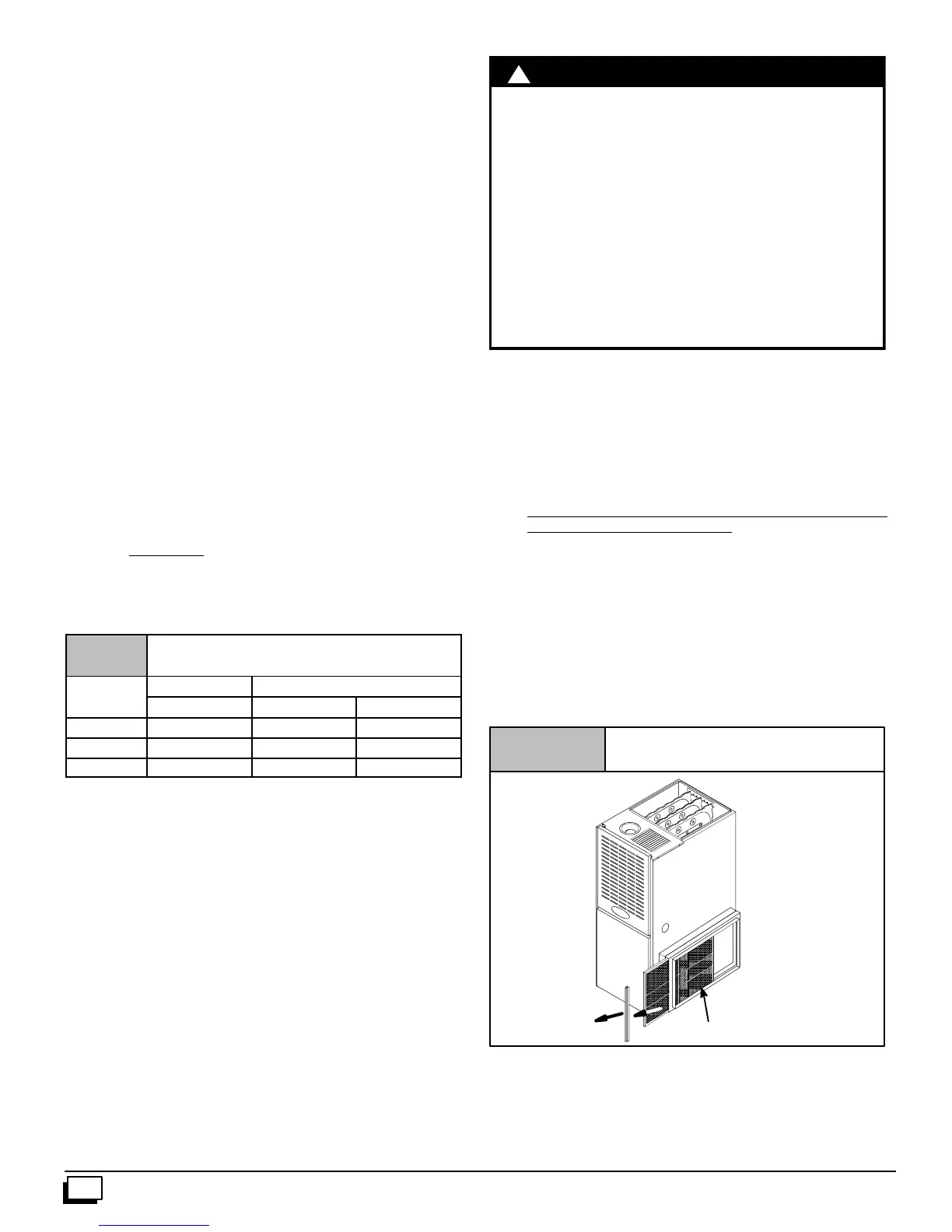

Figure 22

Optional Duct Standoff

20x25Optional

Filter Rack

Filter

25--23--05--4

Optional Filter Rack Installation: Side Return

Centerthefilterrackonthesidepanel,flushwiththebottomedge

ofthefurnace. Mark the fastening holes. Drillthe fastening holes

inthes idepanelandfastenthefilterrackinplacewithsheetmetal

screws. See Figure 23 and Figure 24.

Loading...

Loading...