440 01 4300 00 23

Specifications subject to change without notice.

Roll−Out Protection

Provide a minimum 12−in. x 22−in. (305 x 559 mm) piece of

sheet metal for flame roll−out protection in front of burner area

for furnaces closer than 12−in. (305 mm) above the

combustible deck or suspended furnaces closer than 12−in.

(305mm) to joists. The sheet metal MUST extend underneath

the furnace casing by 1−in. (25mm) with the door removed.

The bottom closure panel may be used for flame roll−out

protection when bottom of furnace is used for return air

connection. See Figure 26 for proper orientation of roll−out

shield.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This opening

shall be accessible when the furnace is installed and shall be of

such a size that the heat exchanger can be viewed for possible

openings using light assistance or a probe can be inserted for

sampling the air stream. The cover attachment shall prevent

leaks.

Connect supply−air duct to flanges on furnace supply−air

outlet. Bend flange upward to 90 with wide duct pliers. (See

Figure 22) The supply−air duct must be connected to ONLY

the furnace supply−outlet−air duct flanges or air conditioning

coil casing (when used). DO NOT cut main furnace casing side

to attach supply air duct, humidifier, or other accessories. All

supply−side accessories MUST be connected to duct external

to furnace main casing.

Return Air Connections

The return−air duct may be connected to bottom of the furnace.

The side of casing that faces downward may also be used for

return air connection. A combination of the bottom and

downward facing side may also be used. The upward facing

side of the casing cannot be used as a return air connection.

(See Figure 29)

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed

in bottom return−air opening. Remove this panel when bottom

return air is used. This panel may be used for rollout protection

or discarded. To remove bottom closure panel, perform the

following:

1. Tilt or raise furnace and remove four (4) screws holding

bottom plate. (See Figure 19)

2. Remove bottom plate.

3. Remove bottom closure panel.

4. Reinstall bottom plate and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed

in bottom return−air opening. This panel MUST be in place

when side return air inlet(s) are used without a bottom return air

inlet.

Not all horizontal furnaces are approved for side return air

connections (See Figure 29)

Filter Arrangement

! WARNING

FIRE, CARBON MONOXIDE AND POISONING HAZARD

Failure to follow this warning could result in personal injury, or

death.

Never operate a furnace without a filter or filtration device

installed. Never operate a furnace with filter or filtration device

access doors removed.

Furnaces shipped without a filter rack:

There are no provisions for an internal filter in these furnaces.

An external filter rack is required and is purchased separately.

A field supplied accessory air cleaner may also be used in

place of the filter rack.

For upflow applications, the filter can be installed on either side

of the furnace, the bottom of the furnace or any combination of

side and bottom of the furnace. (See Figure 28, Figure 30, and

Figure 31)

For downflow applications, the filter rack (or field supplied

accessory air cleaner) must only be connected to the bottom

opening on the furnace (See Figure 27 and Figure 31 and

Table 9).

For horizontal applications, the filter rack (or field supplied

accessory air cleaner) can be connected to the bottom opening

on the furnace. For side return use in the horizontal position,

refer to Figure 29. If both side and bottom openings are used in

Figure 29, each opening used will require a filter.

A filter rack or any field supplied accessory air cleaner can also

be installed in the common return duct prior to entering the

return air opening in any orientation.

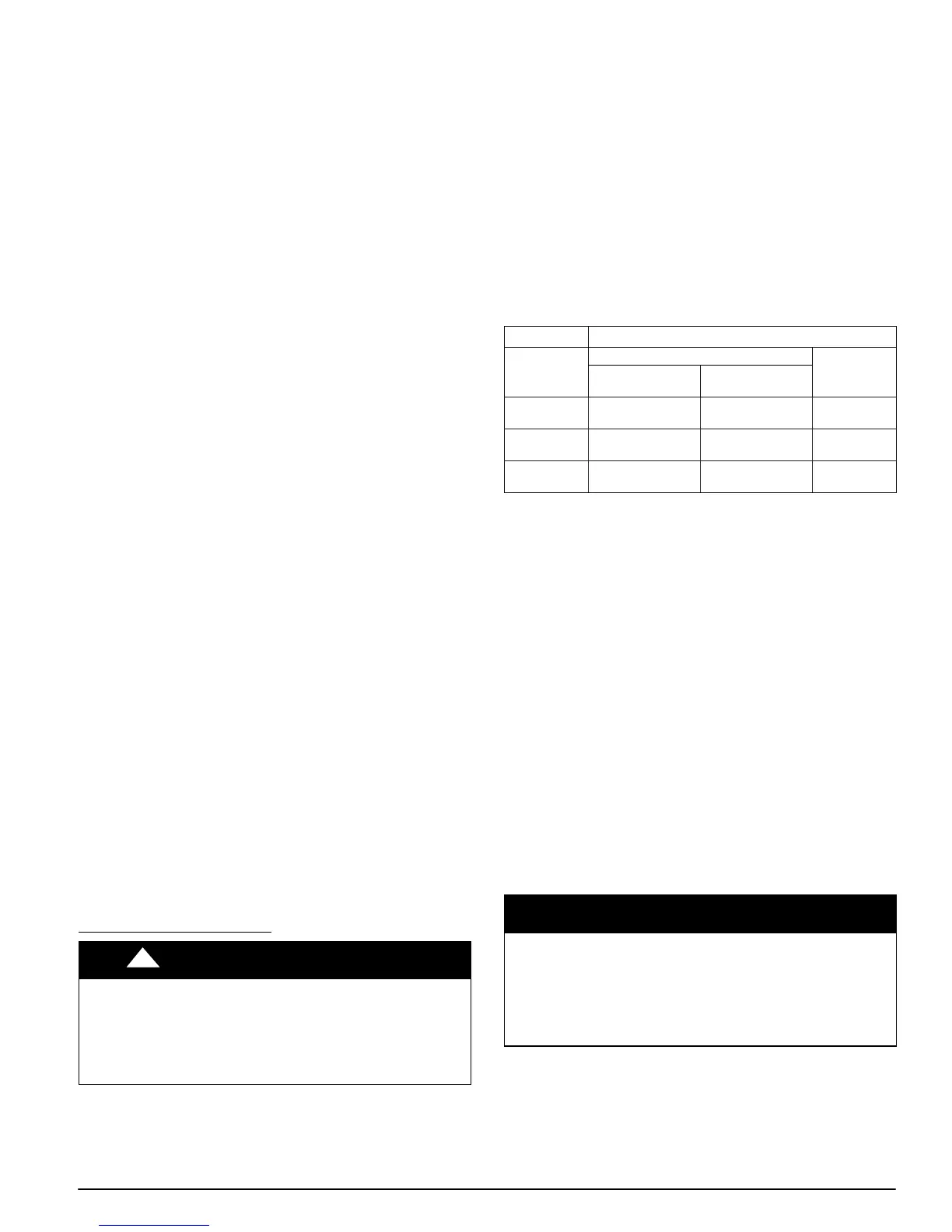

See Table 6 for recommended filter size details.

Table 6 Filter Size Information − inch (mm)

FURNACE

CASING

WIDTH

FILTER SIZE

FILTER

TYPE

SIDE RETURN

BOTTOM

RETURN

17-1/2

(445)

16 x 25 x 3/4

(406 x 635 x 19)

16 x 25 x 3/4

(406 x 635 x 19)

Washable*

21 (533)

16 x 25 x 3/4

(406 x 635 x 19)

20 x 25 x 3/4

(508 x 635 x 19)

Washable*

24-1/2

(622)

16 x 25 x 3/4

(406 x 635 x 19)

24 x 25 x 3/4

(610 x 635 x 19)

Washable*

* Recommended to maintain air filter face velocity. See Product Data for part

number.

Refer to the instructions supplied with the Filter Rack or

accessory air filter for additional assembly and installation

options.

Filter and Return Duct Sizing

Pressure drop must be taken into account when sizing filters,

filter racks, IAQ devices, and associated system ductwork. See

Table 7 for a comparison of Pressure Drop (initial/clean

resistance to airflow) versus Airflow for a variety of filter media

types and sizes. These are representative numbers. Consult

the filter or IAQ device manufacturers’ specification sheet for

performance data for a particular filter media or IAQ device.

Design the filter and associated ductwork for the best match of

pressure drop versus filter size. Best practice usually chooses filter

systems with pressure drops under 0.2 in. w.c. (50 Pa), with the

best blower electrical efficiency and system airflow performance

occurring with filter pressure drops under 0.1 in. w.c. (25 Pa).

Due to the relatively high pressure drops of 1-in (25 mm) thick

after-market filter media, it is recommended that the filtration

system be designed for at least 2-in (51 mm) thick media.

TIPS FROM CONTRACTORS: Install a media cabinet capable

of incorporating a 4-in (102 mm) thick media filter. This allows

room for future upgrades to other IAQ devices.

NOTICE

Design the duct system FIRST to determine how much pres-

sure drop may be allowed in the filter system. See the AIR

DUCTS section. Excessive filter pressure drop often com-

promises system airflow and duct performance, causes inad-

equate airflow to the furthest ends of the duct system, as well

as causes excess noise and higher than anticipated electrical

consumption.

Provide duct transitions, as required, to smoothly transition airflow

from the return duct system to the filter (or IAQ device) to the

furnace when the dimensions of the ductwork or furnace return air

opening do not match the required filter or IAQ device dimensions.

See the instructions supplied with factory-accessory duct

adapters.

Loading...

Loading...