FIRE AND/OR EXPLOSION HAZARD

Failure to follow this warning could result in

property damage, personal injury, and/or death.

• TURN OFF GAS SUPPLY AND ELECTRICAL

POWER TO YOUR UNIT BEFORE SERVICING OR

PERFORMING MAINTENANCE.

• Do not turn off electrical power to this unit without first

turning off the gas supply.

• When removing access panels or performing

maintenance functions inside your unit, be aware of

Do NOT attempt to light the pilot or burner with a

match or flame of any kind.

ROUTINE MAINTENANCE

sharp sheet metal parts and screws. Although special

care is taken to reduce sharp edges to a minimum, be

extremely careful when handling parts or reaching

into the unit.

All routine maintenance should be handled by skilled,

experienced personnel. Your dealer can help you establish

a standard procedure.

For your safety, keep the unit area clear and free of

combustible materials, gasoline, and other flammable

liquids and vapors.

To assure proper functioning of the unit, flow of combustion

and ventilating air must not be obstructed from reaching the

unit. Clearance of at least 30 in. is required on all sides

except the duct side.

MAINTENANCE AND CARE FOR THE

EQUIPMENT OWNER

Before proceeding with those things you might want to

maintain yourself, please carefully consider the following:

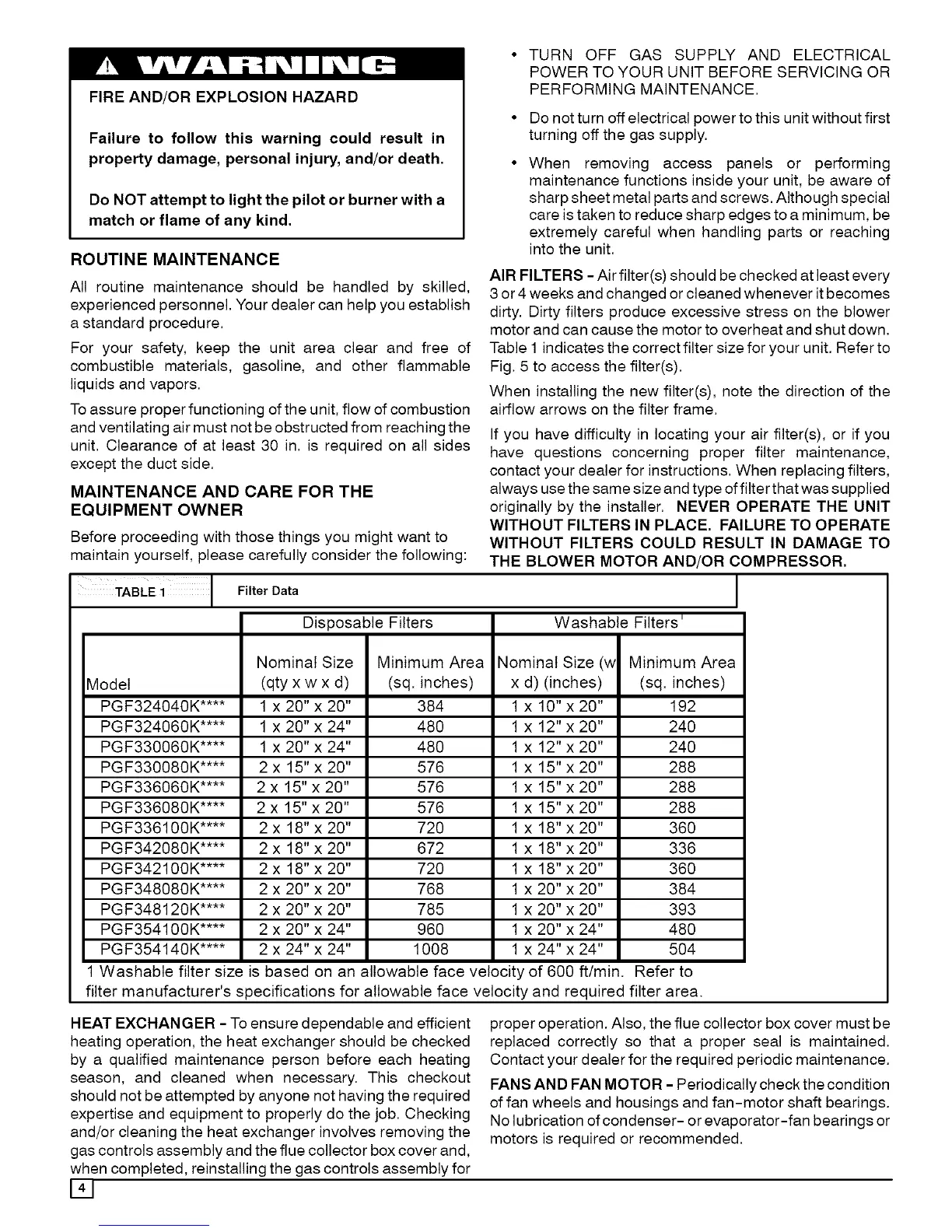

TABLE 1 Filter Data

AIR FILTERS - Air filter(s) should be checked at least every

3 or 4 weeks and changed or cleaned whenever it becomes

dirty. Dirty filters produce excessive stress on the blower

motor and can cause the motor to overheat and shut down.

Table 1 indicates the correct filter size for your unit. Refer to

Fig. 5 to access the filter(s).

When installing the new filter(s), note the direction of the

airflow arrows on the filter frame.

If you have difficulty in locating your air filter(s), or if you

have questions concerning proper filter maintenance,

contact your dealer for instructions. When replacing filters,

always use the same size and type of filter that was supplied

originally by the installer. NEVER OPERATE THE UNIT

WITHOUT FILTERS IN PLACE. FAILURE TO OPERATE

WITHOUT FILTERS COULD RESULT IN DAMAGE TO

THE BLOWER MOTOR AND/OR COMPRESSOR,

Disposable Filters Washable Filters'

Nominal Size Minimum Area Nominal Size (_ Minimum Area

Model (qty x w x d) (sq. inches) x d) (inches) (sq. inches)

PGF324040K .... 1 x 20" x 20" 384 1 x 10" x 20" 192

PGF324060K .... 1 x 20" x 24" 480 1 x 12" x 20" 240

PGF330060K .... 1 x 20" x 24" 480 1 x 12" x 20" 240

PGF330080K .... 2 x 15" x 20" 576 1 x 15" x 20" 288

PGF336060K .... 2 x 15" x 20" 576 1 x 15" x 20" 288

PGF336080K .... 2 x 15" x 20" 576 1 x 15" x 20" 288

PGF336100K .... 2x 18" x 20" 720 1 x 18" x 20" 360

PGF342080K .... 2 x 18" x 20" 672 1 x 18" x 20" 336

PGF342100K .... 2x 18" x 20" 720 1 x 18" x 20" 360

PGF348080K .... 2 x 20" x 20" 768 1 x 20" x 20" 384

PGF348120K .... 2 x 20" x 20" 785 1 x 20" x 20" 393

PGF354100K .... 2 x 20" x 24" 960 1 x 20" x 24" 480

PGF354140K .... 2 x 24" x 24" 1008 1 x 24" x 24" 504

1 Washable filter size is based on an allowable face velocity of 600 ft/min. Refer to

filter manufacturer's specifications for allowable face velocity and required filter area.

HEAT EXCHANGER - To ensure dependable and efficient

heating operation, the heat exchanger should be checked

by a qualified maintenance person before each heating

season, and cleaned when necessary. This checkout

should not be attempted by anyone not having the required

expertise and equipment to properly do the job. Checking

and/or cleaning the heat exchanger involves removing the

gas controls assembly and the flue collector box cover and,

when completed, reinstalling the gas controls assembly for

141

proper operation. Also, the flue collector box cover must be

replaced correctly so that a proper seal is maintained.

Contact your dealer for the required periodic maintenance.

FANS AND FAN MOTOR - Periodically check the condition

of fan wheels and housings and fan-motor shaft bearings.

No lubrication of condenser- or evaporator-fan bearings or

motors is required or recommended.

Loading...

Loading...