8. SEQUENCE OF OPERATION

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

Cooling Operation (PHF324 -42)

With a call for cooling (Y), the indoor fan energizes

immediately where as the contactor energizes after a 5

minute time delay (incase of an initial start up) starting the

compressor and the outdoor fan motor. When the cooling

demand ismet, (Y) de-energizes, shutting the compressor,

indoor fan and the outdoor fan.

Cooling Operation (PHF348)

These units utilize a 2 stage indoorthermostat. With a first

stage call for cooling (Y1), the indoor fan (low stage)

energizes immediately where as the contactor energizes

after a 5 minute time delay (incase of an initial start up)

starting the compressor (low stage) and the outdoor fan

motor. If the low stage operation cannot satisfy the cooling

demand, the second stage cooling (Y2) energizes

switching the compressor into high stage cooling through

energizing an internal solenoid valve inside the scroll

compressor and switching the indoor fan into high stage.

When second stage cooling is satisfied, Y2 de-energizes

switching the compressor and the indoor fan into low stage

cooling. When the low stage cooling demand is met, Y1

de-energizes shutting the compressor, indoor fan and the

outdoor fan.

Heating Operation (PHF324 -42)

With a call for heating (Y), the indoor fan (low stage)

energizes immediately where as the contactor energizes

after a 5 minute time delay (incase of an initial start up)

starting the compressor and the outdoor fan motor. If (Y)

cannot satisfy the heating demand, the auxiliary or back up

heat (W2) energizes. Incase of staged heating, W3 is

energized if the demand is not met. The highest airflow

selected is run while the electric heat is in operation. When

heating demand is met, W3, W2 and Y sequentially

de-energize shutting the compressor, indoor fan and the

outdoor fan.

Heating Operation (PHF348)

With a first stage call for heating (Y1), the indoor fan (low

stage) energizes immediately whereas the contactor

energizes after a 5 minute time delay (incase of an initial

start up) starting the compressor (low stage) and the

outdoor fan motor. If the low stage operation cannot satisfy

the heating demand, the second stage heating (Y2)

energizes switching the compressor into high stage heating

through energizing an internal solenoid valve inside the

scroll compressor and switching the indoor fan into high

stage. The auxiliary or back up heat is controlled by a third

stage (W2). If the demand is not met, W3 is energized in

case of staged heating. When heating demand is satisfied,

W3, W2 and Y2 sequentially de-energize switching the

compressor and the indoor fan into low stage heating.

When the low stage heating demand is met, Y1

de-energizes shutting the compressor, indoor fan and the

outdoor fan.

Scroll Recycle Delay timer

The defrost board is equipped with a recycle delay timer

which will delay the start of the compressor for 5 minutes in

the event of a power interruption. This sequences power

throughout the system and prevents possible reverse

rotation of the scroll compressor. The output of the timer

controls the compressor contactor via a normally open

contact of K3 (T2). The timer starts the delay cycle when the

compressor is turned off by removal of "Y." If application of

"Y" occurs before the timer has expired, the compressor

contactor will not be energized until the timer has expired.

CONTINUOUS FAN OPERATION

With the continuous Indoor fan option selected on the

thermostat, G is continuously energized. Incase of 024 -

042 units, the selected airflow setting is provided. In case of

048 units, the system runs low stage (Y1) airflow for

continuous fan operation.

Defrost Mode

On a call for defrost:

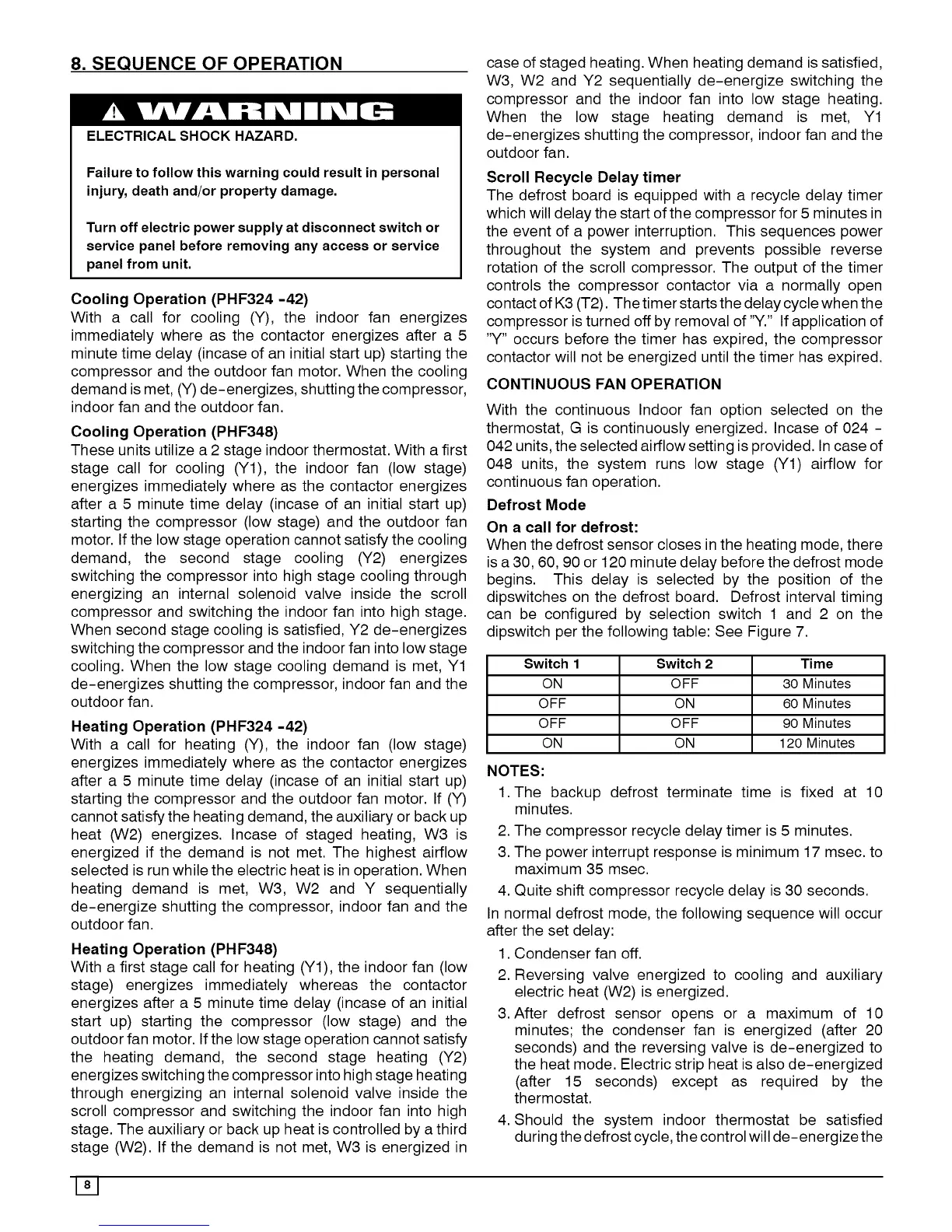

When the defrost sensor closes in the heating mode, there

is a 30, 60, 90 or 120 minute delay before the defrost mode

begins. This delay is selected by the position of the

dipswitches on the defrost board. Defrost interval timing

can be configured by selection switch 1 and 2 on the

dipswitch per the following table: See Figure 7.

Switch 1

ON

OFF

OFF

ON

NOTES:

1. The backup

minutes.

Switch 2 Time

OFF 30 Minutes

ON 60 Minutes

OFF 90 Minutes

ON 120 Minutes

defrost terminate time is fixed at 10

2. The compressor recycle delay timer is 5 minutes.

3. The power interrupt response is minimum 17 msec. to

maximum 35 msec.

4. Quite shift compressor recycle delay is 30 seconds.

In normal defrost mode, the following sequence will occur

after the set delay:

1. Condenser fan off.

2. Reversing valve energized to cooling and auxiliary

electric heat (W2) is energized.

3. After defrost sensor opens or a maximum of 10

minutes; the condenser fan is energized (after 20

seconds) and the reversing valve is de-energized to

the heat mode. Electric strip heat is also de-energized

(after 15 seconds) except as required by the

thermostat.

4.

Should the system indoor thermostat be satisfied

during the defrost cycle, the control will de-energize the

Loading...

Loading...