Do NOT install the unit in a location that will permit

discharged air from the condenser to recirculate to the

condenser inlet,

UNIT DAMAGE HAZARD

Failure to follow this caution may result in shorten life

of unit components.

Do NOT operate unit in a corrosive atmosphere

containing chlorine, fluorine, or any other corrosive

chemicals.

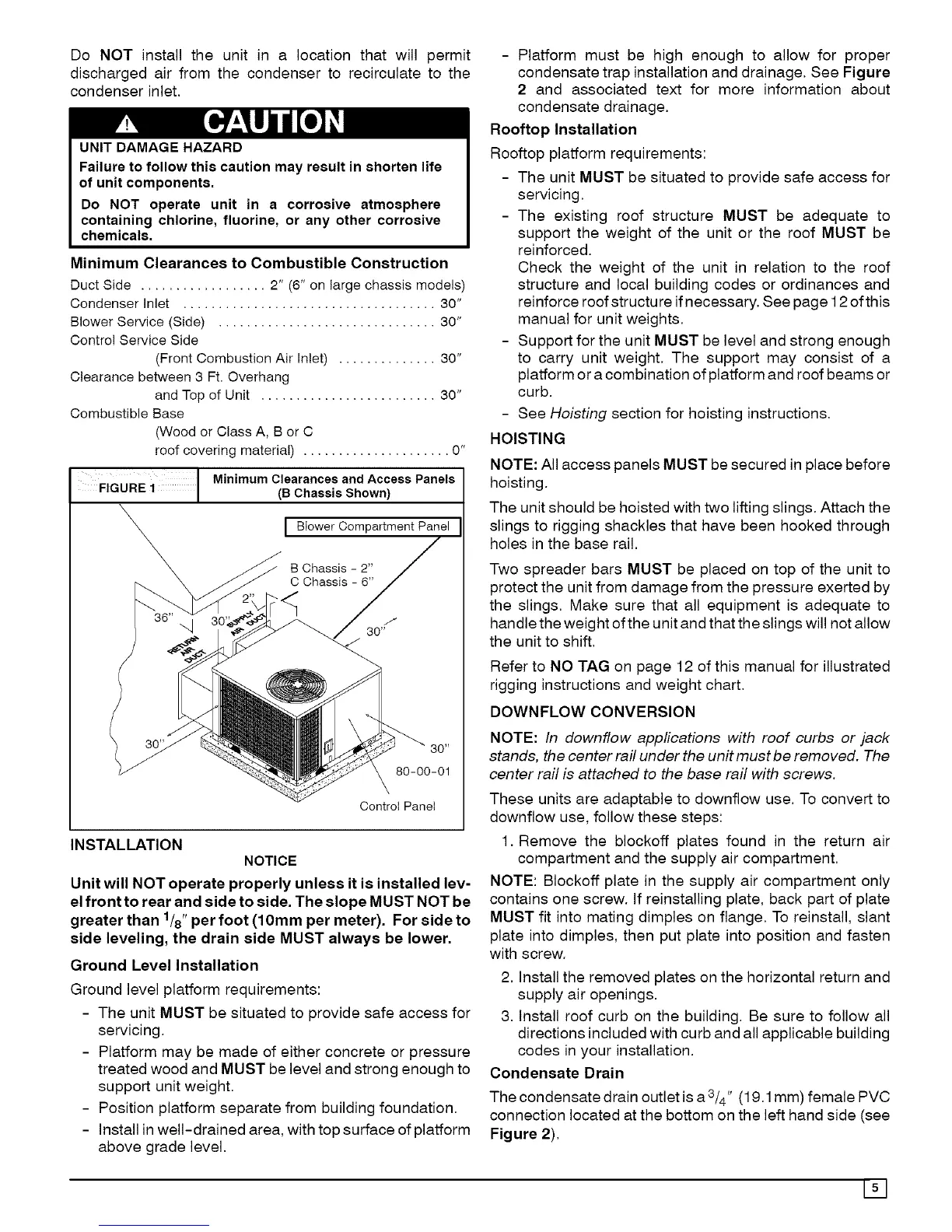

Minimum Clearances to Combustible Construction

DuctSide .................. 2" (6" on largechassis models)

Condenser Inlet .................................... 30"

BlowerService (Side) ............................... 30"

Control Service Side

(Front Combustion Air Inlet) .............. 30"

Clearance between 3 Ft. Overhang

and Top of Unit ......................... 30"

Combustible Base

(Woodor Class A, B or C

roof covering material) ..................... 0"

Minlmomc,earoooosoodAooesspano,sCho si Shownl

Biower Compartment Panel

B Chassis - 2"

C Chassis - 6"

80"

80-00-01

Control Panet

INSTALLATION

NOTICE

Unit will NOT operate properly unless it is installed lev-

el front to rear and side to side. The slope MUST NOT be

1 ,

greater than /8 perfoot (10mm per meter). For side to

side leveling, the drain side MUST always be lower.

Ground Level Installation

Ground level platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support unit weight.

Position platform separate from building foundation.

Install in well-drained area, with top surface of platform

above grade level.

- Platform must be high enough to allow for proper

condensate trap installation and drainage. See Figure

2 and associated text for more information about

condensate drainage.

Rooftop Installation

Rooftop platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- The existing roof structure MUST be adequate to

support the weight of the unit or the roof MUST be

reinforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structu re if necessary. See page 12 of this

manual for unit weights.

- Support for the unit MUST be level and strong enough

to carry unit weight. The support may consist of a

platform or a combination of platform and roof beams or

curb.

- See Hoisting section for hoisting instructions.

HOISTING

NOTE: All access panels MUST be secured in place before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings, Make sure that all equipment is adequate to

handle the weight ofthe unit and that the slings will not allow

the unit to shift,

Refer to NO TAG on page 12 of this manual for illustrated

rigging instructions and weight chart,

DOWNFLOW CONVERSION

NOTE: In downflow applications with roof curbs or jack

stands, the center rail under the unit must be removed. The

center rail is attached to the base rail with screws.

These units are adaptable to downflow use, To convert to

downflow use, follow these steps:

1. Remove the blockoff plates found in the return air

compartment and the supply air compartment.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten

with screw.

2. Install the removed plates on the horizontal return and

supply air openings.

3, Install roof curb on the building. Be sure to follow all

directions included with curb and all applicable building

codes in your installation.

Condensate Drain

The condensate drain outlet is a 3/4'' (19.1 mm) female PVC

connection located at the bottom on the left hand side (see

Figure 2),

151

Loading...

Loading...