3.1 SERVICING SCHEDULE

For the very latest copy of literature for specication & maintenance practices, visit our website www.idealboilers.com, where you

will be able to download the relevant information.

WARNING. Always turn OFF the gas supply at the gas service cock, and switch OFF and disconnect the electricity

supply to the appliance before servicing.

Combustion testing must be carried out by a competent person using a combustion analyser conforming to BS7927.

To ensure the continued safe and efcient operation of the appliance it is recommended that it is checked at regular intervals and

serviced as necessary. The frequency of servicing will depend upon the installation condition and usage but should be carried out

at least annually.

It is the law that any service work must be carried out by a Gas Safe Registered Engineer. In IE service work must be carried out

by a Registered Gas Installer (RGII).

INSPECTION

1. Light the boiler and carry out a pre-service check, noting any

operational faults.

2. Check the ue terminal (and terminal guard if tted) is

undamaged and clear of any obstruction.

3. Check all water and gas joints for signs of leakage. Remake

any suspect joints ensuring a gas tightness check is carried

out if applicable and the water system is correctly relled,

vented and re-pressurised.

CLEANING PROCEDURE

Note. In order to carry out either servicing or replacement of

components the boiler front panel must be removed.

Refer to Section 3.2.

1. Clean the main burner. Refer to Section 3.4.

2. Clean the heat exchanger & condensate trap/siphon. Refer to

Section 3.5 & 3.6.

3. Check the main injector for blockage or damage. Refer to

Section 3.10.

4. Check that the ue terminal is unobstructed and that the ue

system is sealed correctly.

ALSO IF THE DHW FLOW RATE IS IN QUESTION :-

5. Check the DHW lter for blockage. Refer to Section 3.25.

The cleaning procedures are covered more fully in Sections 3.3

to 3.7 and MUST be carried out in sequence.

IMPORTANT.

6. After completing the servicing or exchange of components

always test for gas tightness.

7. When work is complete the front panel MUST be correctly

retted, ensuring that a good seal is made.

Do NOT OPERATE the boiler if the front panel is

not tted.

8. If, for any reason, the condensate trap/siphon has been

removed ensure the trap is relled with water before

reassembling.

9. Check the gas consumption.

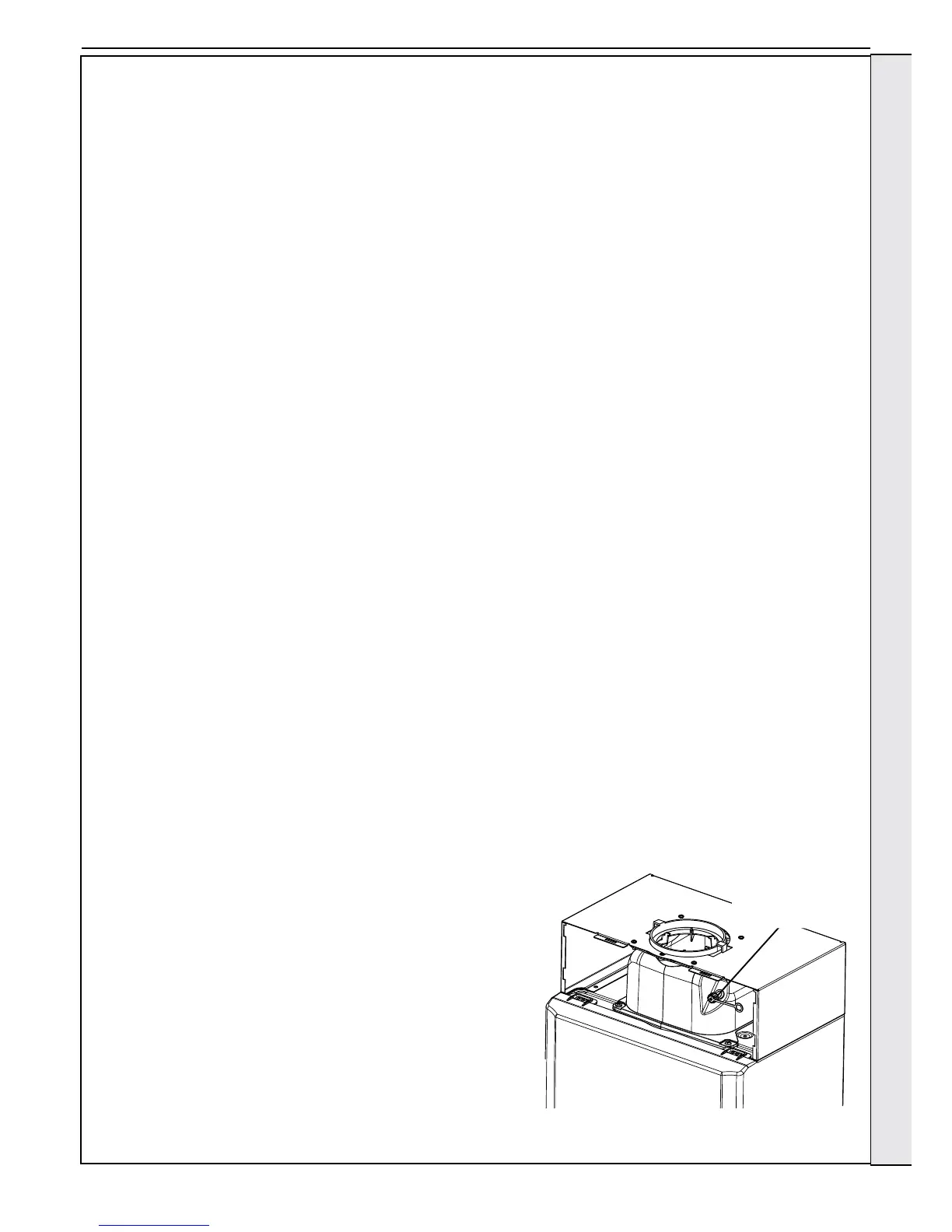

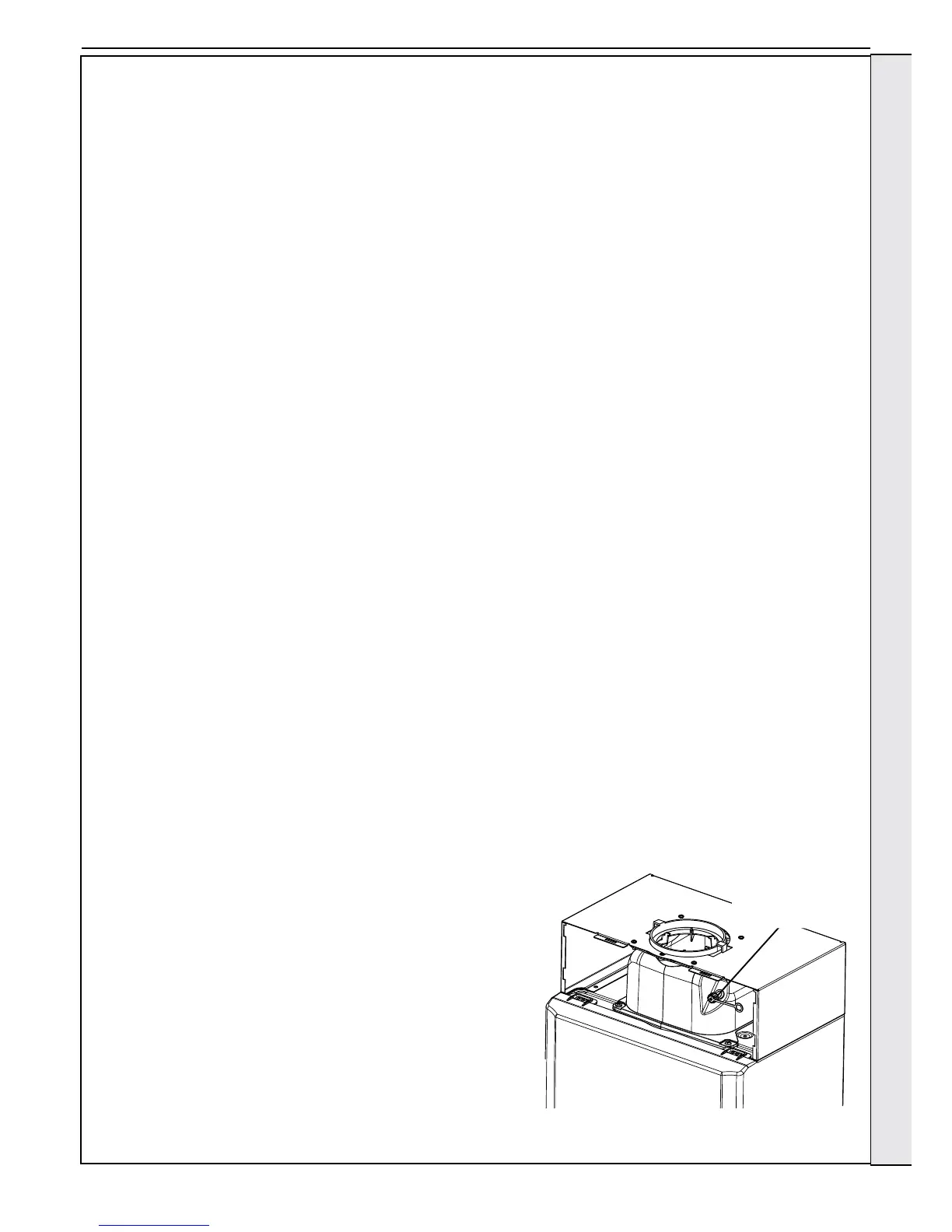

10. Check combustion by connecting the ue gas analyser to the

ue gas sampling point as shown in the diagram and measure

CO & CO

2

.

If the CO/CO

2

ratio is greater than 0.004 AND the integrity of

the complete ue system and combustion circuit seals have

been veried and the inlet gas pressure (and gas rate) have

been veried, then contact Ideal.

11. Complete the service section in the Benchmark

Commissioning Checklist.

GENERAL

Please Note: During routine servicing, and after any

maintenance or change of part of the combustion

circuit, the following must be checked:

- The integrity of the ue system and the ue seals,

- The integrity of the boiler combustion circuit and

the relevant seals

- The operational (working) gas inlet pressure at

maximum rate

- The gas rate

- The combustion performance

COMPETENCE TO CARRY OUT THE

COMBUSTION PERFORMANCE CHECK

Please Note: BS 6798:2009 Specication for

installation and maintenance of gas-red boilers of

rated input not exceeding 70kW net advises that:

- The person carrying out a combustion

measurement should have been assessed as

competent in the use of a ue gas analyser and the

interpretation of the results

- The ue gas analyser used should be one meeting

the requirements of BS7927 or BS-EN50379-3

and be calibrated in accordance with the analyser

manufacturer’s requirements, and

- Competence can be demonstrated by satisfactory

completion of the CPA1 ACS assessment, which

covers the use of electronic portable combustion

gas analysers in accordance with BS7967, Parts 1

to 4

Flue Sampling

Point

SERVICING

Loading...

Loading...