INSTALLAT ION

Mini --- Installation & Servicing

16

11 FITTING THE FLUE SYSTEM (cont.)

Co---axial Flue kits.

Horizontal.

For calculation of total flue length, the distance MUST be

measured from the centreline of the concentric elbow to the

end of the terminal grille.

Vertical outlet

For calculation of total flue length, the distance MUST be

measured from the centreline of the outlet connector at the

boiler top panel to the end of the terminal grille.

For each additional 45˚ and 90˚ flue bend used, the

maximum permissible length of flue system must be reduced

by 1m or 1,5m respectively.

Horizontal and Vertical Outlet kits (60 --- 100) have a minimum

300mm length, up to a maximum shown in tables 7 & 8.

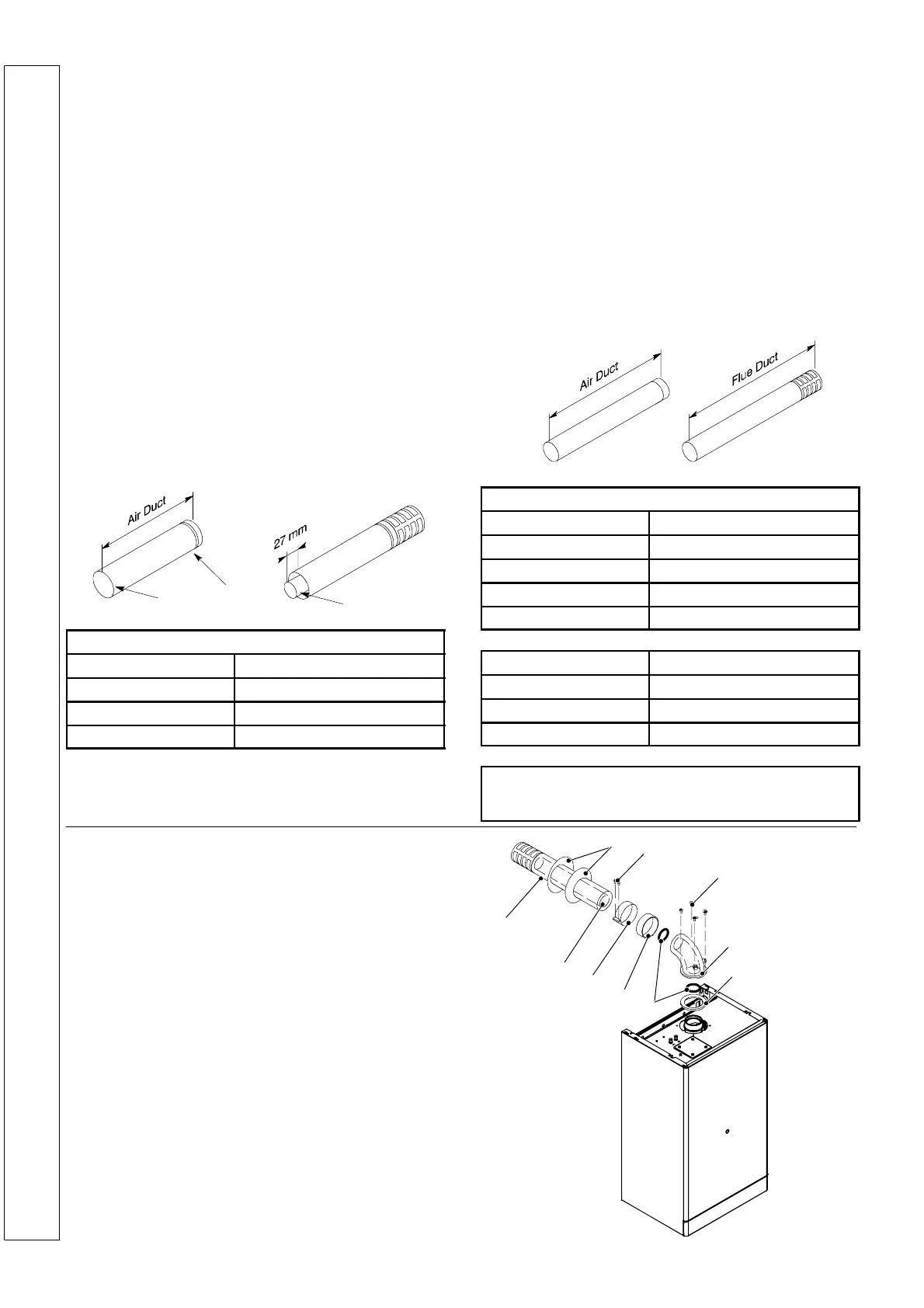

Cutting lengths of flue and air ducts

Measure the wall thickness and, when using a side outlet, the

gapbetweentheinnerwallandtheboilersidecasing.

Use the following chart to calculate the cutting length of air

duct.

Completely insert the flue duct in the air duct.

Mark and cut the flue duct so it protrudes 27 mm from the air

duct edge.

Groove

Cut this end

Flue duct

12

Horizontal Concentric

Air duct

Rear Outlet Wall thickness + 67 mm

Rear outlet + Stand ---off W all thickness + 102 mm

S i d e O u t l e t --- L H & R H Wall thickness + Gap + 120mm

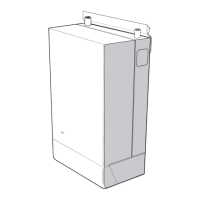

Twin pipe flue kits

For calculation of total flue length, the distance MUST be

measured from the centreline of the flue duct/air duct

connection to the end of the flue outlet grille/air inlet duct.

For each additional 45˚ M&F and 90˚ M&F flue bend used,

themaximumpermissiblelengthoffluesystemmustbe

reduced by 0,9m or 1,65m respectively.

For each additional 90˚ F&FFluebendused,themaximum

permissiblelengthoffluesystemmustbereducedby2,75m.

Lengths of allowable equivalent flue outlet and air inlet ducts

are indicated in the graphs within this frame.

N.B.: The air intake and flue outl et must not terminate on

opposite sides of the building.

Cutting lengths of flue and air ducts

Measure the wall thickness and, when using a side outlet, the

gap between the inner wall and the boiler side casing. Use

the following chart to calculate the cutting lengths of both flue

and air ducts.

Twin Pip e

Air duct

Rear Outlet W all thickness + 215 mm

Rear outlet + Stand--- off Wall thickness + 250 mm

Side Outlet --- LH Wall thickness + Gap + 83 mm

Side Outlet --- RH Wall thickness + Gap + 273mm

Flue Duct + Grille

Rear Outlet W all thickness + 225 mm

Rear outlet + Stand--- off Wall thickness + 260 mm

Side Outlet --- LH & RH W all thickness + Gap + 278mm

When installing a horizontal flue system, Co---axial or

Twin Pipe, all ducts MUST have a fall of 3% AWAY from

the boiler.

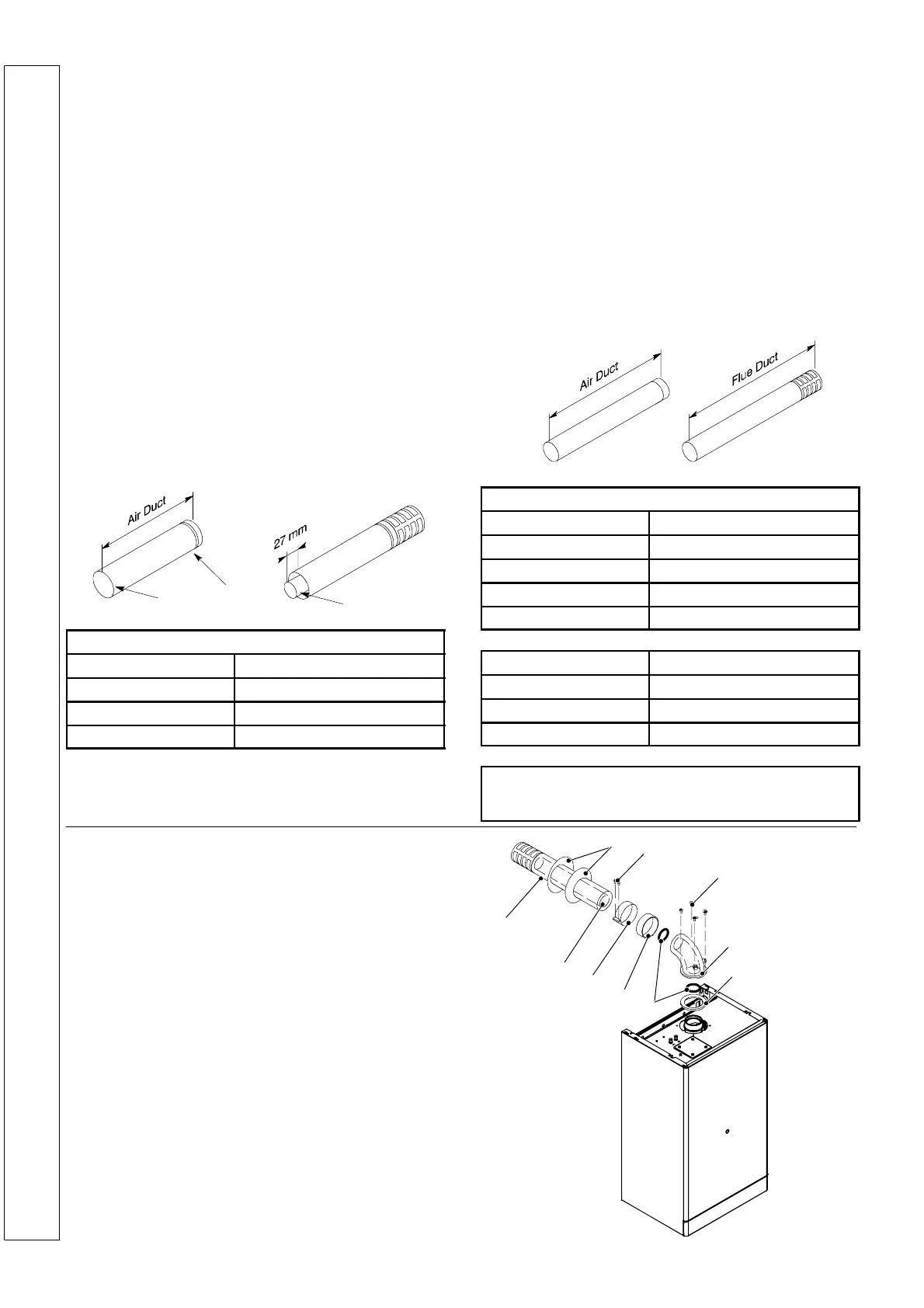

12 REAR FLUE ASSEMBLY

Legend

1 Wall finishing gaskets

2 Self tapping screw 4,2x13

3 Self tapping screws 4,8x13

4 Flue turret

5 Boiler ---turret gasket

6 Fluepipegaskets

7 Turret---air pipe gasket

8Band

9 Flue pipe ø 60 mm with terminal grille assembly

10 Air intake pipe ø 100 mm

9

10

8

7

6

5

4

3

1

2

INSTALLATION

Loading...

Loading...