45

INSTALLATION

Solar Thermal - Installation and Servicing

PUMP STATION

Safety Relief Valve / Pressure Gauge Assembly

The Hydraulic solar pump station in the Ideal solar package is equipped with a 6 bar pressure relief valve which should be connected

via 22mm pipe work terminating in a suitable container. An empty canister of heat transfer uid can be used for this purpose .

Drain Valve

It is good practice to install a suitable drain valve at the lowest point in the system to facilitate draining of the solar system if required.

Connecting the Solar Cylinder

Refer to solar cylinder manufacturer’s instructions for installation, observing the correct direction of ow through the cylinder coil. Refer

to Frame 1.

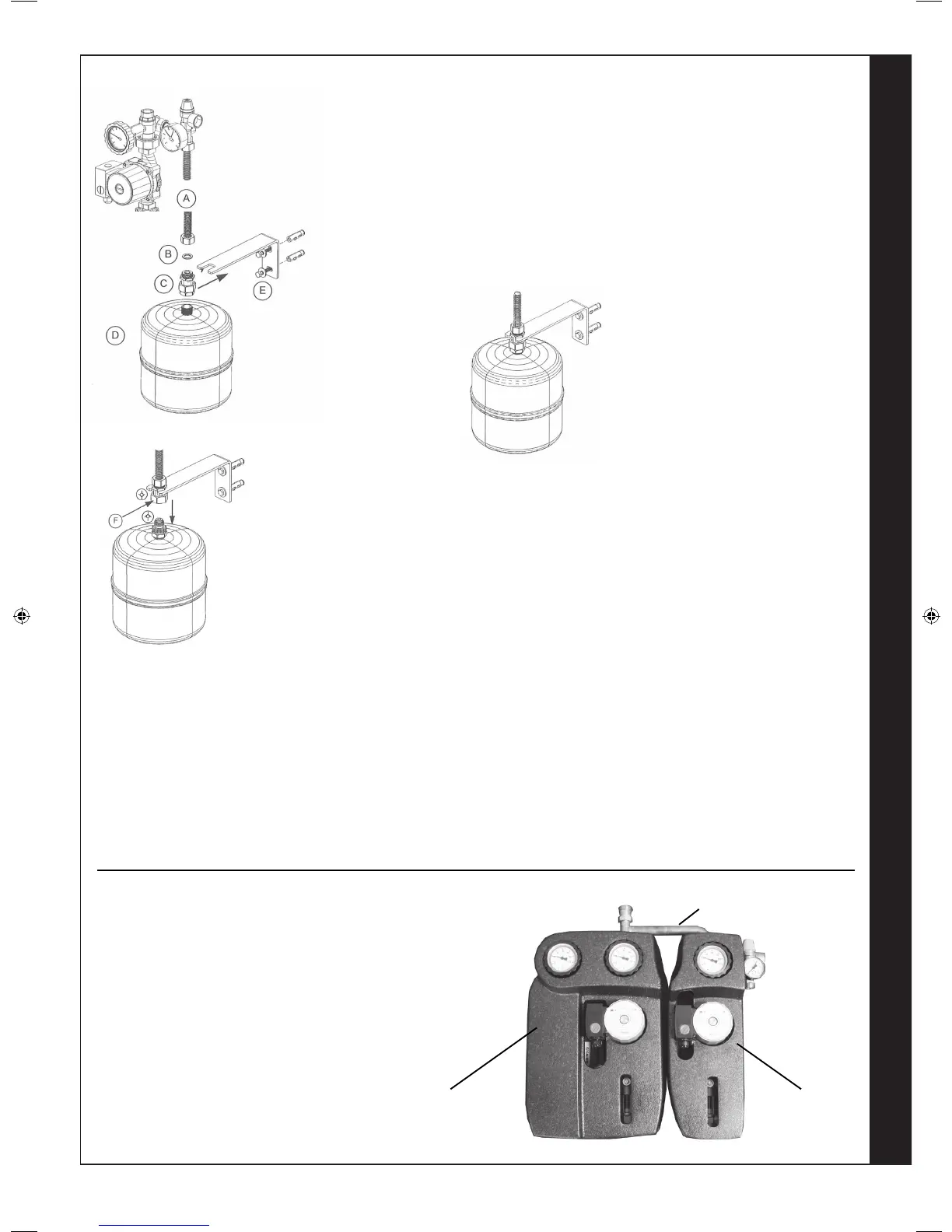

Double Return Kit

If additional ow capacity is requried the single line

pump station (Ideal Part No. UIN 207072) can be

employed. within this kit an additional collector

return pump and connector tee is provided. During

installation the safety relief valve and pressure

gauge is transferred from the twin line pump station

to the single line station.

A ow gauge is provided in the single line pump

station so the ow rate between the two ow rates

can be balanced.

The single line pump station is also employed when

installing solar panels in East-West conguration.

Twin line

pump station

Single line

pump station

Tee Connection

40

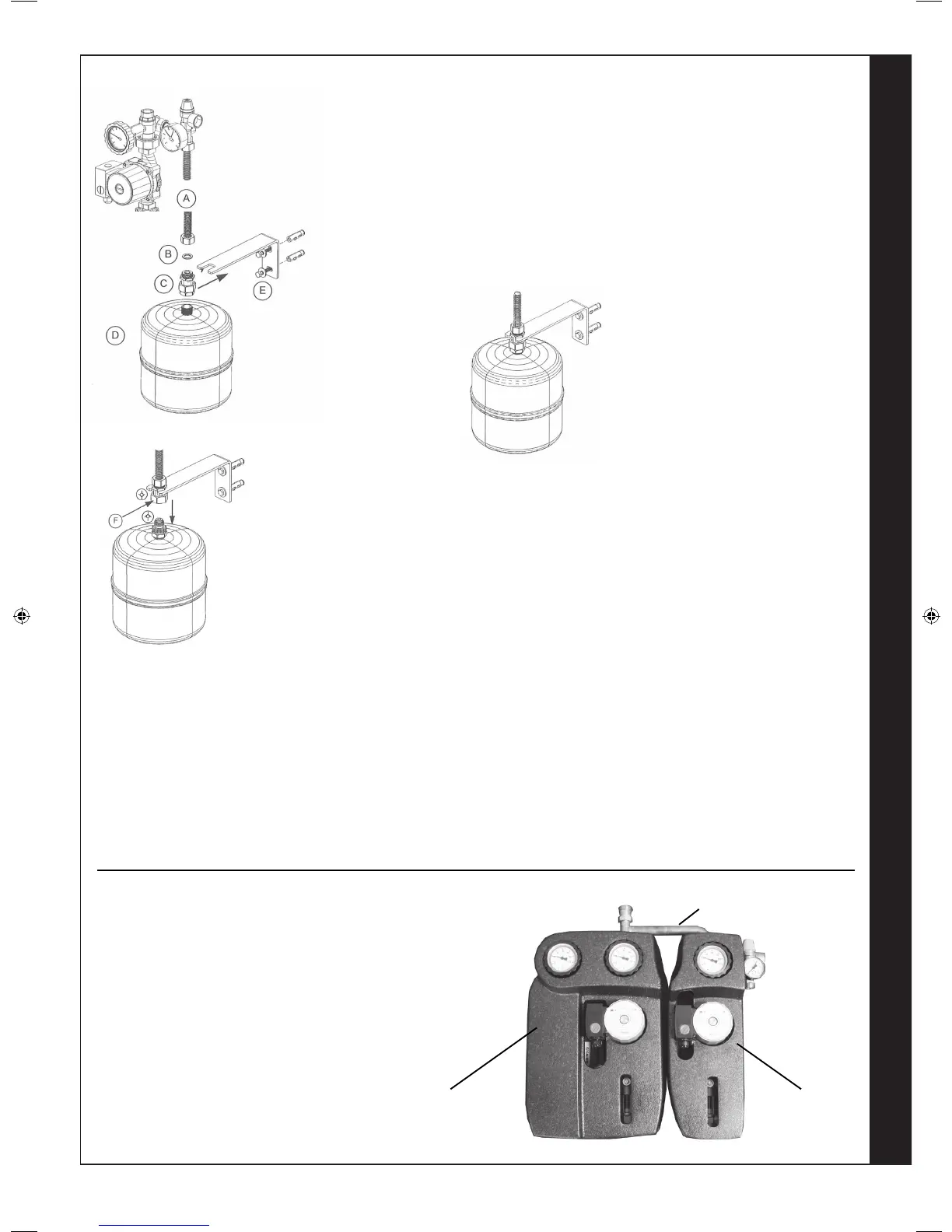

BRACKET AND CONNECTION KIT FOR THE EXPANSION VESSEL

A. 3/4” exible pipe connected to the security unit of the solar pumping

station (not included).

B. Fibre sealing joint inlcuded.

C. Connector with double check valve to disconnect the expansion vessel

in a reliable and fast way without any leakage.

D. Expansion vessel with 3/4” threaded connection (available on request).

E. Fixing bracket provided with plugs and screws to x it to the wall

Fix the bracket (E) to the wall with the plugs (centre distance 55mm)

Screw the expansion vessel (D) to the connector (C) and put it on the

xing bracket using the special groove then lock with the nut.

Put the sealing joint (B) and screw the exible pipe of the security unit (A)

to the connector.

Replacement of the Expansion Vessel

The connector (C) holds up the expansion vessel and allows a quick detachment of it avoiding

any leakage.

By unscrewing the nut (F) it is possible to disconnect one end of the connector that remains

screwed to the expansion vessel. The other end of the connector stays xed on the bracket

connected to the security unit.

both ends have a check valve that becomes operative at the time of the disconnection: this

prevents any leakage both from the expansion vessel and from the exible pipe.

To ret the expansion vessel connect the two ends of the connector and to x them by screwing

the nut (F). In that way the two check valves are disconnected and the expansion vessel is

again connected to the installation.

207786-2.indd 45 16/02/2012 11:26:23

Loading...

Loading...