FanCoils

INSTALLATION,OPERATION,&MAINTENANCEMANUAL

12

SECTIONTHREE—NormalOperation&PeriodicMaintenance

package,dependingonunitconguration.Itistheuser’s

responsibilitytoensurethetubeandpipingmaterials

furnishedbyIEC,arecompatiblewiththetreatedwater.

Failure to provide proper water quality will void the fan

coil unit’s warranty.

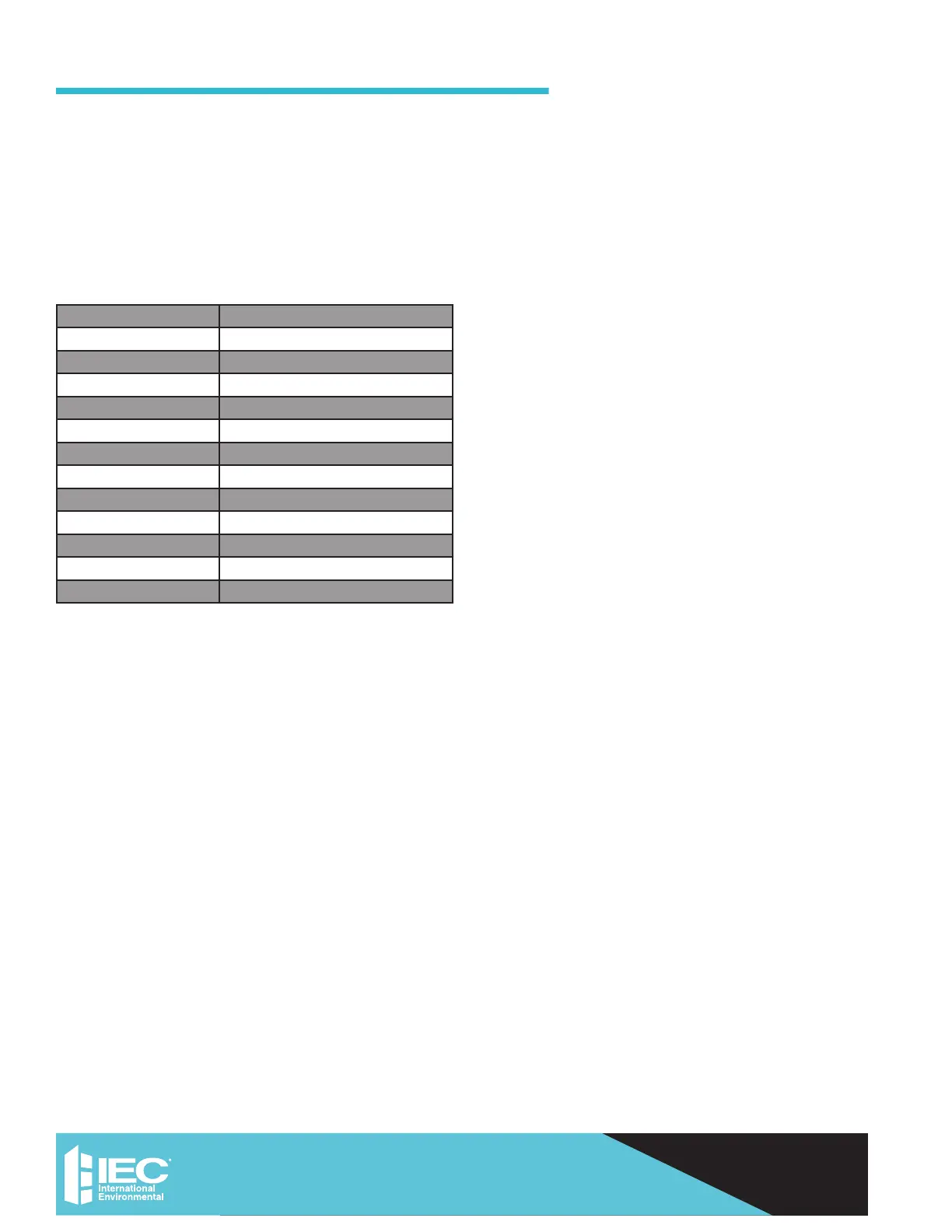

Water Containing Required Concentration

Sulphate Less than 200 ppm

pH 7.0 – 8.5

Chlorides Less than 200 ppm

Nitrate Less than 100 ppm

Iron Less than 4.5 mg/l

Ammonia Less than 2.0 mg/l

Manganese Less than 0.1 mg/l

Dissolved Solids Less than 1000 mg/l

CaCO3 Hardness 300 - 500 ppm

CaCO3 Alkalinity 300 - 500 ppm

Particulate Quantity Less than 10 ppm

Particulate Size 800 micron max

Water System Balancing

Acompleteknowledgeofthehydronicsystem,alongwith

itscomponentsandcontrols,isessentialtoproperwater

systembalancing.Thisprocedureshouldnotbeattempted

byunqualiedpersonnel.Thesystemmustbecomplete,

andallcomponentsmustbeinoperatingcondition

BEFOREbeginningwatersystembalancingoperations.

Eachhydronicsystemhasdifferentoperatingcharacteristics

dependingonthedevicesandcontrolsusedinthesystem.

Theactualbalancingtechniquemayvaryfromonesystem

toanother.

Afterthepropersystemoperationisestablished,the

appropriatesystemoperatingconditionssuchasvarious

watertemperaturesandowratesshouldberecordedin

aconvenientplaceforfuturereference.

Before,andduringwatersystembalancing,conditions

mayexistduetoincorrectsystempressureswhich

mayresultinnoticeablewaternoiseorundesiredvalve

operation.Aftertheentiresystemisbalanced,these

conditionswillnotexistonproperlydesignedsystems.

Controls Operation

Beforepropercontroloperationcanbeveried,allother

systemsmustbeoperatingproperly.Thecorrectwater

andairtemperaturesmustbepresentforthecontrol

functionbeingtested.Somecontrolsandfeaturesare

designedtonotoperateundercertainconditions.For

example,ona2-pipecooling/heatingsystemwithauxiliary

electricheat,theelectricheatercannotbeenergizedwith

hotwaterinthesystem.

Awiderangeofcontrols,electricaloptionsand

accessoriesmaybeusedwiththeequipmentcovered

inthismanual.Consulttheapprovedunitsubmittals,

orderacknowledgments,andotherliteraturefordetailed

informationregardingeachindividualunitanditscontrols.

Sincecontrolsandfeaturesmayvaryfromoneunitto

another,careshouldbetakentoidentifythecontrols

usedoneachunitandtheirpropercontrolsequence.

Informationprovidedbycomponentmanufacturers

regardinginstallation,operation,andmaintenanceoftheir

individualcontrolsisavailableuponrequest.

SECTIONTHREE–NormalOperation&

PeriodicMaintenance

General

Eachunitonajobwillhaveitsownuniqueoperating

environmentandconditionswhichmaydictatea

maintenancescheduleforthatunitthatisdifferent

fromotherequipmentonthejob.Aformalscheduleof

regularmaintenanceandanindividualunitlogshouldbe

establishedandmaintained.Thiswillhelptoachievethe

maximumperformanceandservicelifeofeachuniton

thejob.

Information regarding safety precautions contained in

the preface at the beginning of this manual should be

followed during any service and maintenance operations.

Formoredetailedinformationconcerningserviceoperations

consultyourSalesRepresentativeorthefactory.

Loading...

Loading...