6

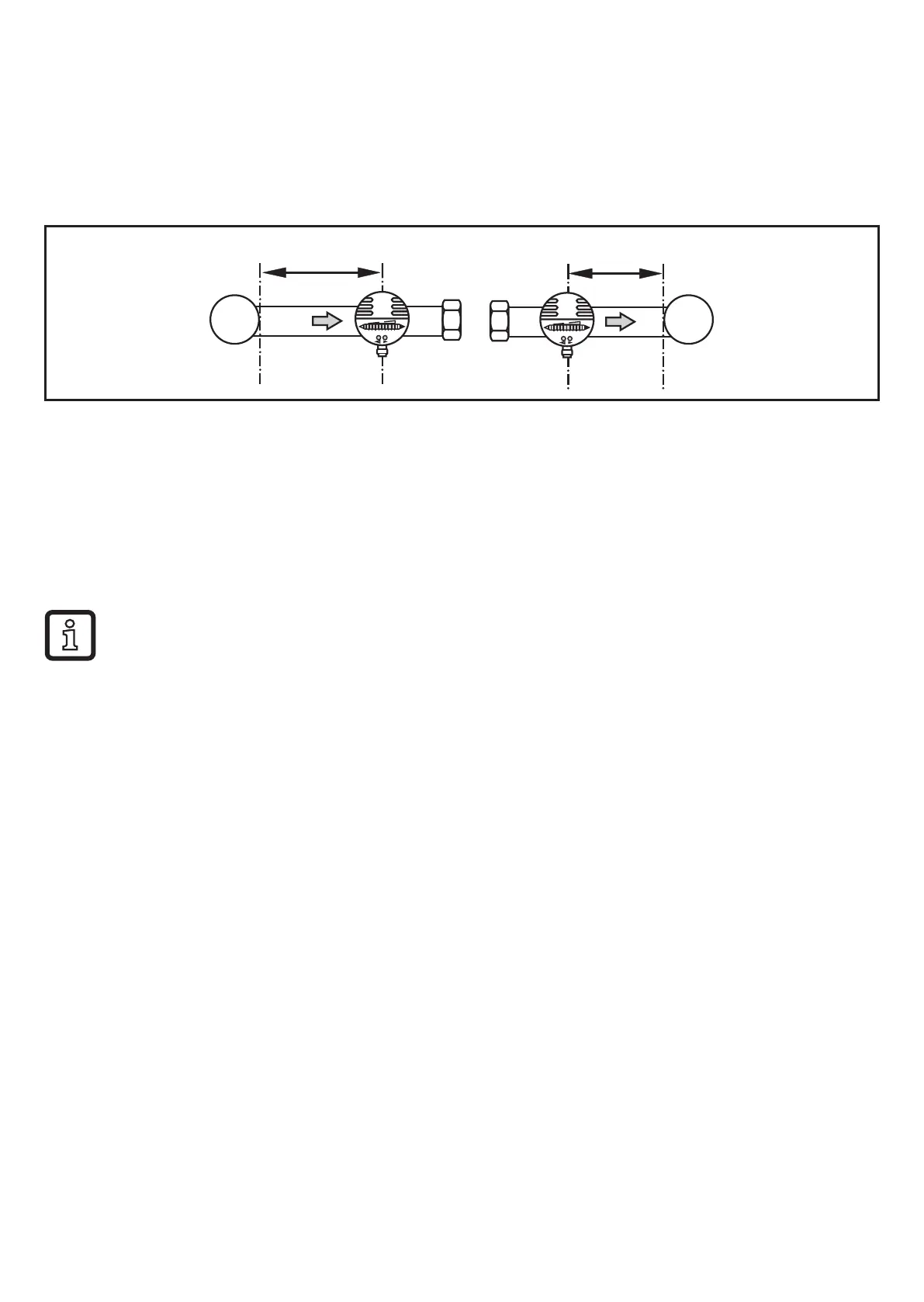

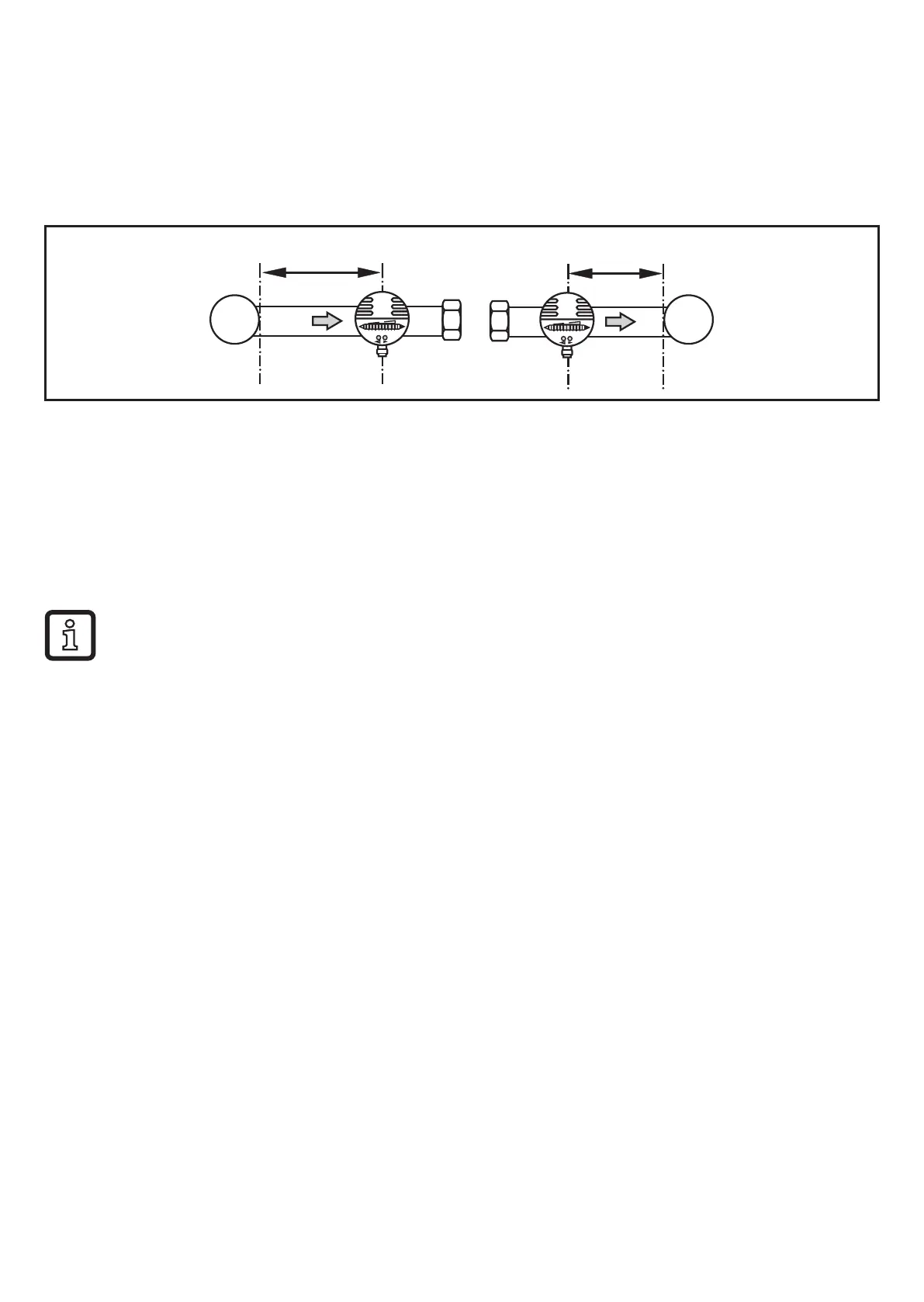

4.2 Interference in the pipe system

Components integrated in the pipes, bends, valves, reductions, etc� lead to

turbulence of the medium� This affects the function of the unit�

Recommendation: Adhere to the distances between sensor and sources of

interference:

D = pipe diameter; S = sources of interference

4.3 Installation procedure

The unit can be fixed to different process connections�

► Insert the unit with process adapter into the process connection and tighten

using a spanner�

Information about available adapters at www�ifm�com�

► Observe the instructions of the adapter�

► Use a lubricating paste which is suitable and approved for the

application�

► Recommended tightening torque 35 Nm�

4.3.1 Installation using an adapter with sealing ring (hygiene-compliant)

Order no� E332xx / E333xx�

► To meet the hygiene regulations use a process adapter with leakage port�

The adapters are supplied with EPDM O-ring (order no� E30054�

More sealing rings are available as accessories:

• FKM O-ring (order no� E30123)

• PEEK sealing ring (order no� E30124)� The PEEK sealing ring is long-term

stable and maintenance-free� When you replace the PEEK sealing ring or

change from a PEEK sealing ring to an O-ring the process adapter also needs

to be replaced with a new equivalent adapter�

Loading...

Loading...