13

1) Oiling port

2) Grease port

3) Sprocket

4. Others

Check for fuel leakage and loose fastenings and dam-

age to major parts, especially handle joints and guide

bar mounting. If any defects are found, make sure to

have them repaired before operating again.

Periodical service points

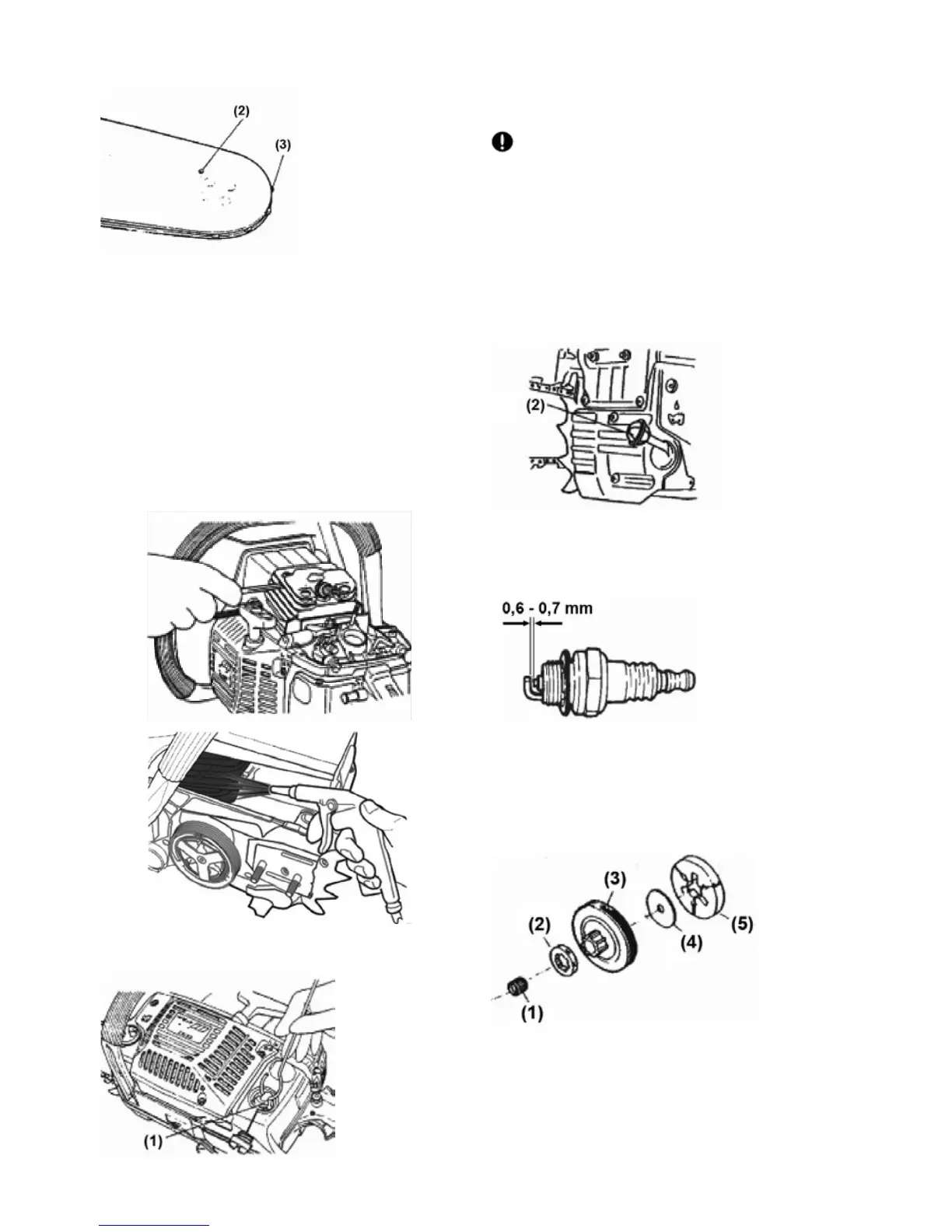

1. Cylinder ns

Dust clogging between the cylinder ns will cause

overheating of the engine. Periodically check and clean

the cylinder ns after removing the air cleaner and the

cylinder cover. When installing the cylinder cover, make

sure that switch wires and grommets are positioned cor-

rectly in place.

2. Fuel lter

a) Using a wire hook, take out the lter from the ller port.

1) Fuel lter

b) Disassemble the lter and wash with gasoline, or

replace with a new one if needed.

IMPORTANT

• After removing the lter, use a pinch to hold the end

of the suction pipe.

• When assembling the lter, take care not to allow lter

bers or dust inside the suction pipe.

3. Oil tank

With a wire hook, take out the oil lter through the ller

port and clean in gasoline. When putting the lter back

into the tank, make sure that it comes to the front right

corner. Also clean off dirt in the tank.

2) Oil lter

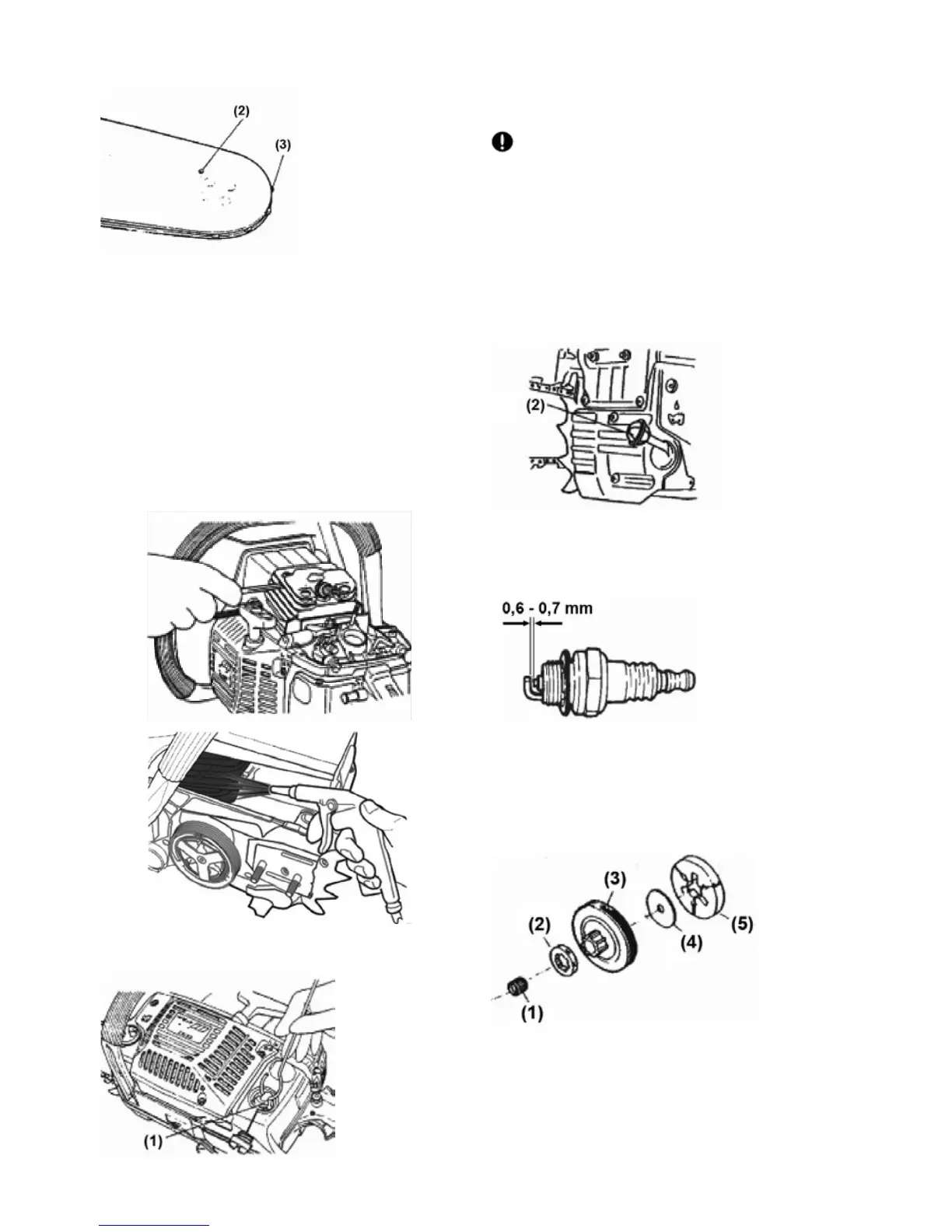

4. Spark plug

Clean the electrodes with a wire brush and reset the gap

to 0.65 mm as necessary.

Spark plug type:

NHSP LD L8RTF or

CDK L7RTC

5. Sprocket

Check for cracks and for excessive wear interfering with

the chain drive. If the wearing is found obviously, re-

place it with a new one. Never t a new chain on a worn

sprocket, or a worn chain on a new sprocket.

1) Needle

bearing

2) Sprocket

3) Clutch drum

4) Washer

5) Clutch block

6. Front and Rear dampers

Replace if adhered part is peeled or crack is observed

on the rubber part.

Loading...

Loading...