Technical documentation

Technical documentation

STEME ed 7/03

13

EOLO MINI

GAS ADJUSTMENTS

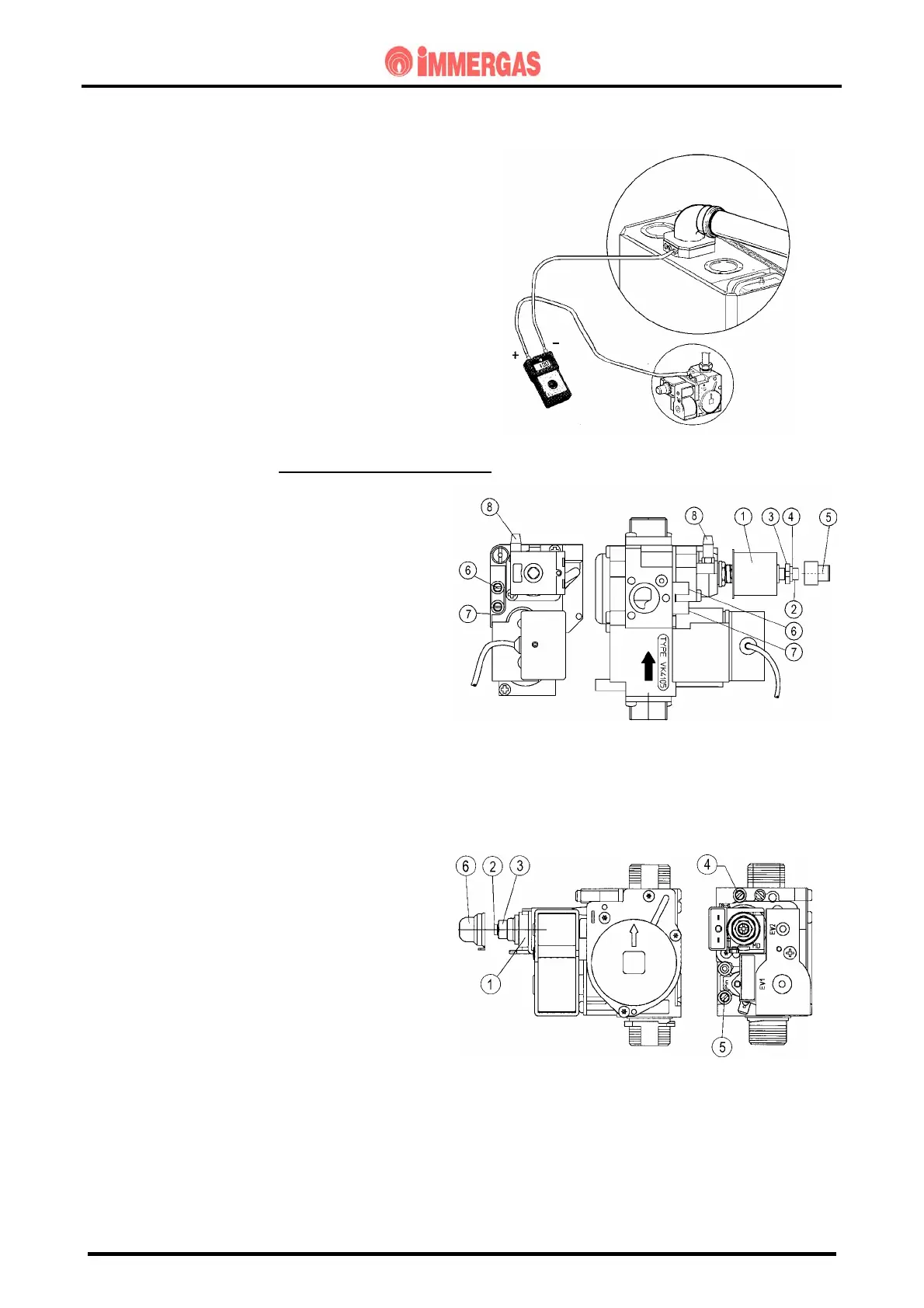

Max and minimum gas pressure adjustments

can be made by means of the gas valve

respecting the values shown on the tables

relating to each boiler for the type of

corresponding gas.

After fitting a pressure gauge, connected to

the gas valve outlet and to the positive

pressure point on the top part of the sealed

chamber (see illustration alongside),

proceed as follows:

- VALVE VK 4105 M (with yellow protection cap)

Minimum pressure adjustment

- After interrupting power to the

modulation coil, turn screw “3” clockwise

to increase pressure to the burner and

anticlockwise to decrease the pressure.

Maximum pressure adjustment

(to be done after minimum pressure

adjustment)

- Sample the d.h.w after setting the

temperature switch on maximum.

Turn nut “4” clockwise to increase the

pressure and anticlockwise to decrease the

pressure.

1) Modulation coil 5) Yellow protection cap

2) Coil pin 6) Gas valve outlet press. point

3) Min. output setscrew 7) Vale inlet press. point

4) Max output setscrew 8) Air press. point

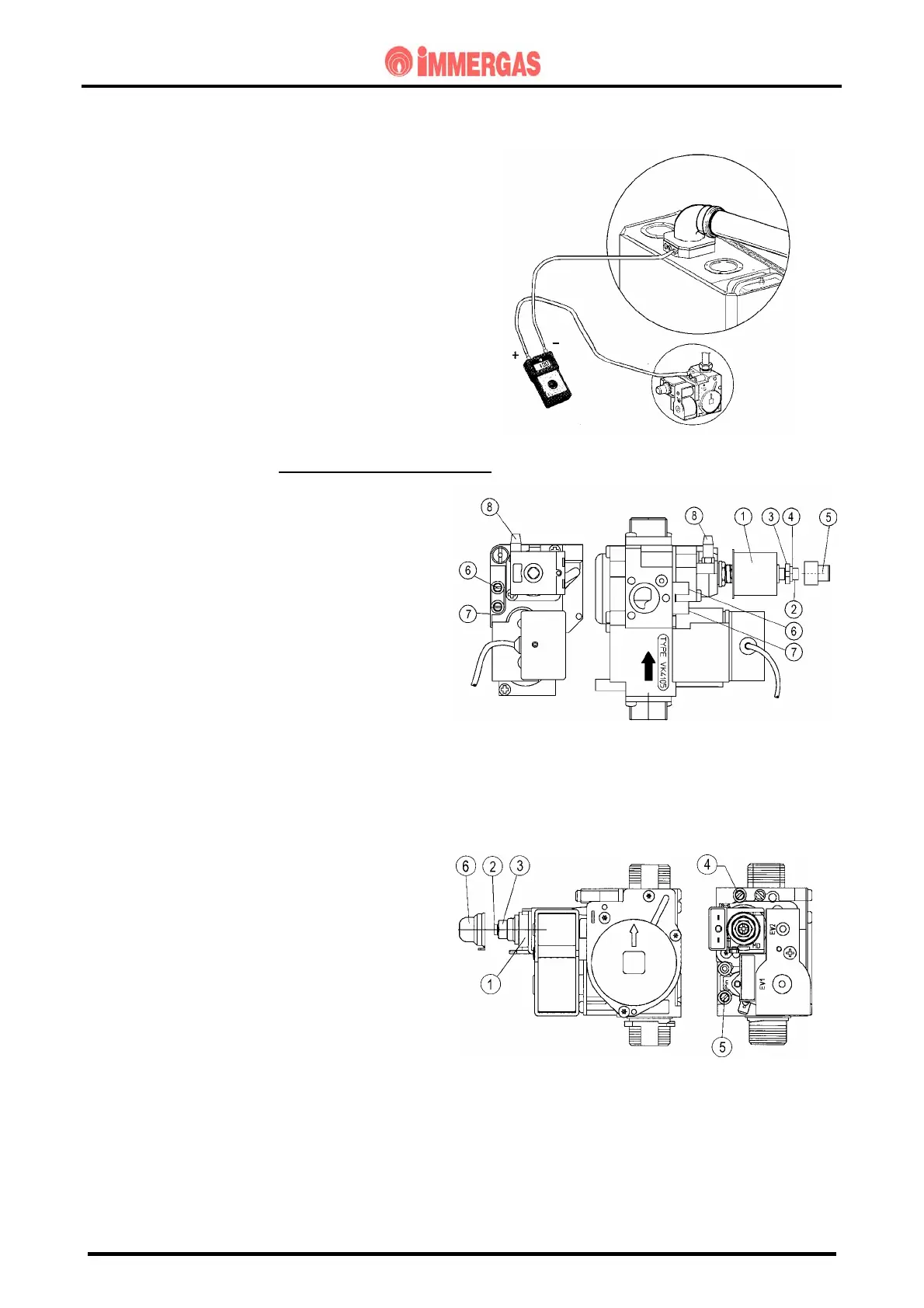

- VALVE SIT 845

Maximum pressure adjustment

- Sample the d.h.w. after setting the

temperature switch at maximum.

Turn nut “3” clockwise to increase the

burner pressure and anticlockwise to

decrease it.

Minimum pressure adjustment

(to be done after maximum pressure

adjustment)

- After interrupting power to the

modulation coil, turn screw “2”

clockwise to increase burner pressure

and anticlockwise to decrease it.

1) Modulation coil

2) Minimum output setscrew

3) Maximum output setscrew

4) Gas valve outlet pressure point

5) Gas valve inlet pressure point

6) Protection cap

Loading...

Loading...