10

1-9

1-10

1-8

1-11

1-12

INSTALLERUSER

MAINTENANCE TECHNICIAN

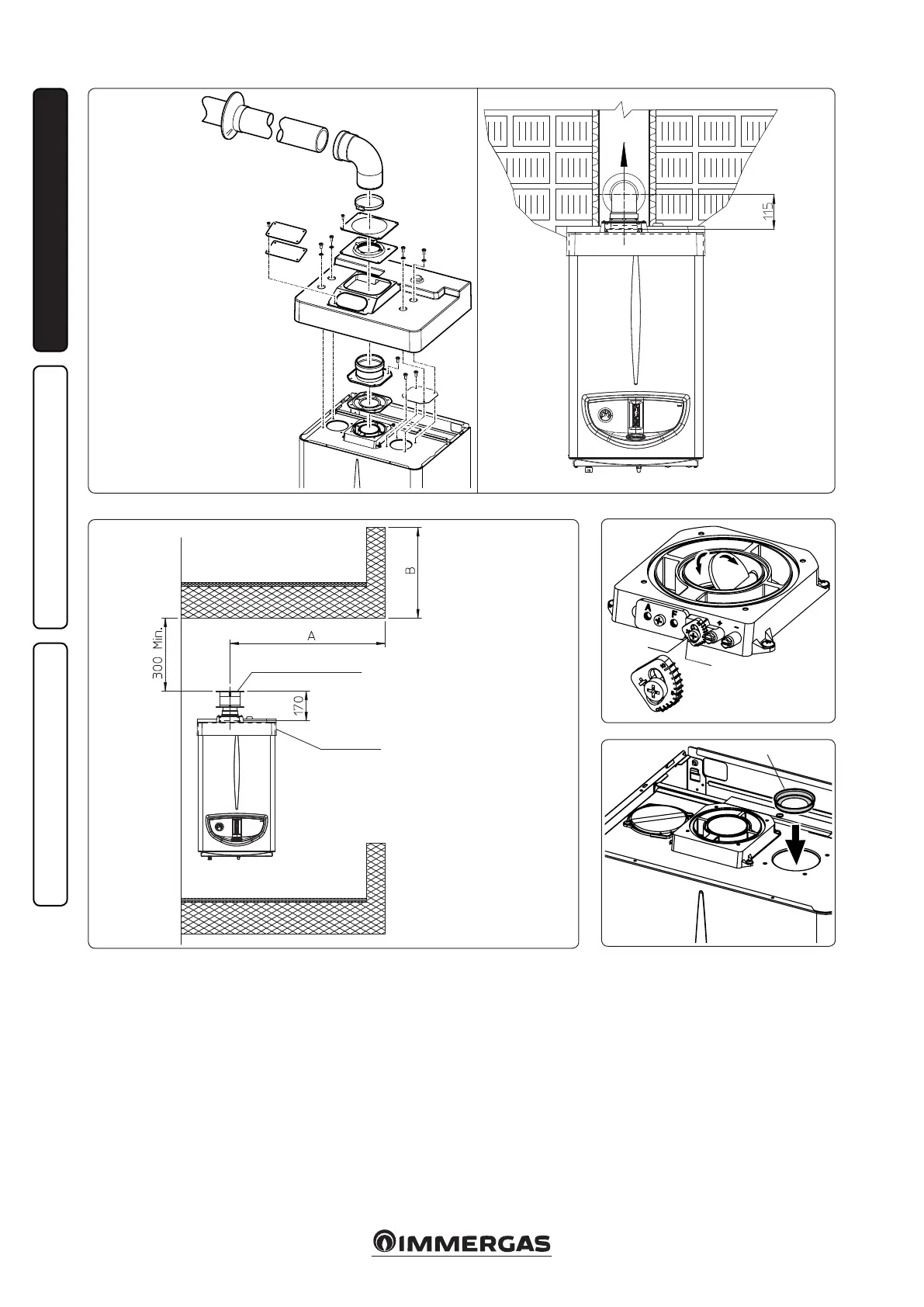

VERTICAL TERMINAL KIT

FOR DIRECT DRAINING

INTAKE

COVER KIT

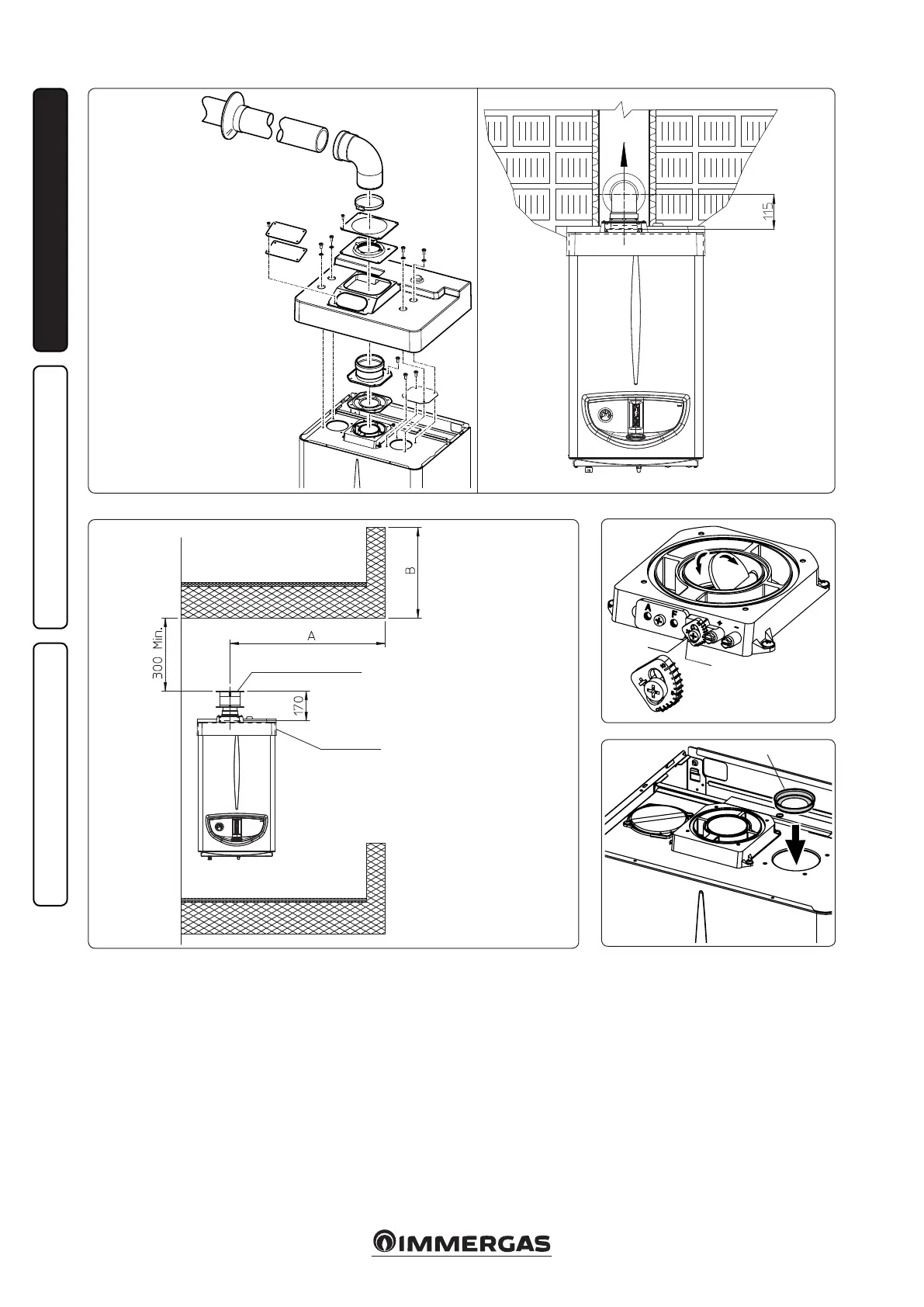

DIAPHRAGM

Flue gas separator adjustment. For correct fun-

ctioning of the boiler it is necessary to regulate

the ue gas shutter positioned on the air/ue gas

sample points (Fig. 1-11).

Adjustment is carried out by loosening the

front retainer screw and moving the indicator

to the correct position, aligning its value to the

horizontal reference. Once adjustment has been

performed, tighten the screw to x the separator.

Appropriate adjustment takes place on the basis

of the type of pipe and its extension: this calcula-

tion can be carried out using the relevant tables.

Intake diaphragm installation. For correct boi-

ler functioning with Ø80 separator kits and drain

measuring > 1 m a diaphragm must be installed

on the sealed chamber intake hole and before

the intake pipe (Fig. 1-12). e choice of suitable

diaphragm takes place on the basis of the type of

pipe and its maximum extension: this calculation

can be carried out using the following tables:

N.B.: the diaphragms are supplied together with

the boiler.

e cover kit includes:

N° 1 Heat moulded cover

N° 1 Gasket clamping plate

N° 1 Gasket

N° 1 Gasket clamp

N° 1 N°1 Intake hole covering

plate

e terminal kit includes:

N° 1 Gasket

N° 1 Exhaust ange Ø80

N° 1 Bend 90° Ø80

N° 1 Exhaust pipe Ø80

N° 1 Wall sealing plate

Loading...

Loading...