20

STMiN3E ed 09/11 MINI NIKE 3 E

Technical DocumentationTechnical Documentation

Gas adjustments

The minimum and maximum pressure adjustments are

performed by acting on the gas valve and must be carried

out respecting the values stated in the tables relative to each

generator for the corresponding type of gas (see technical data).

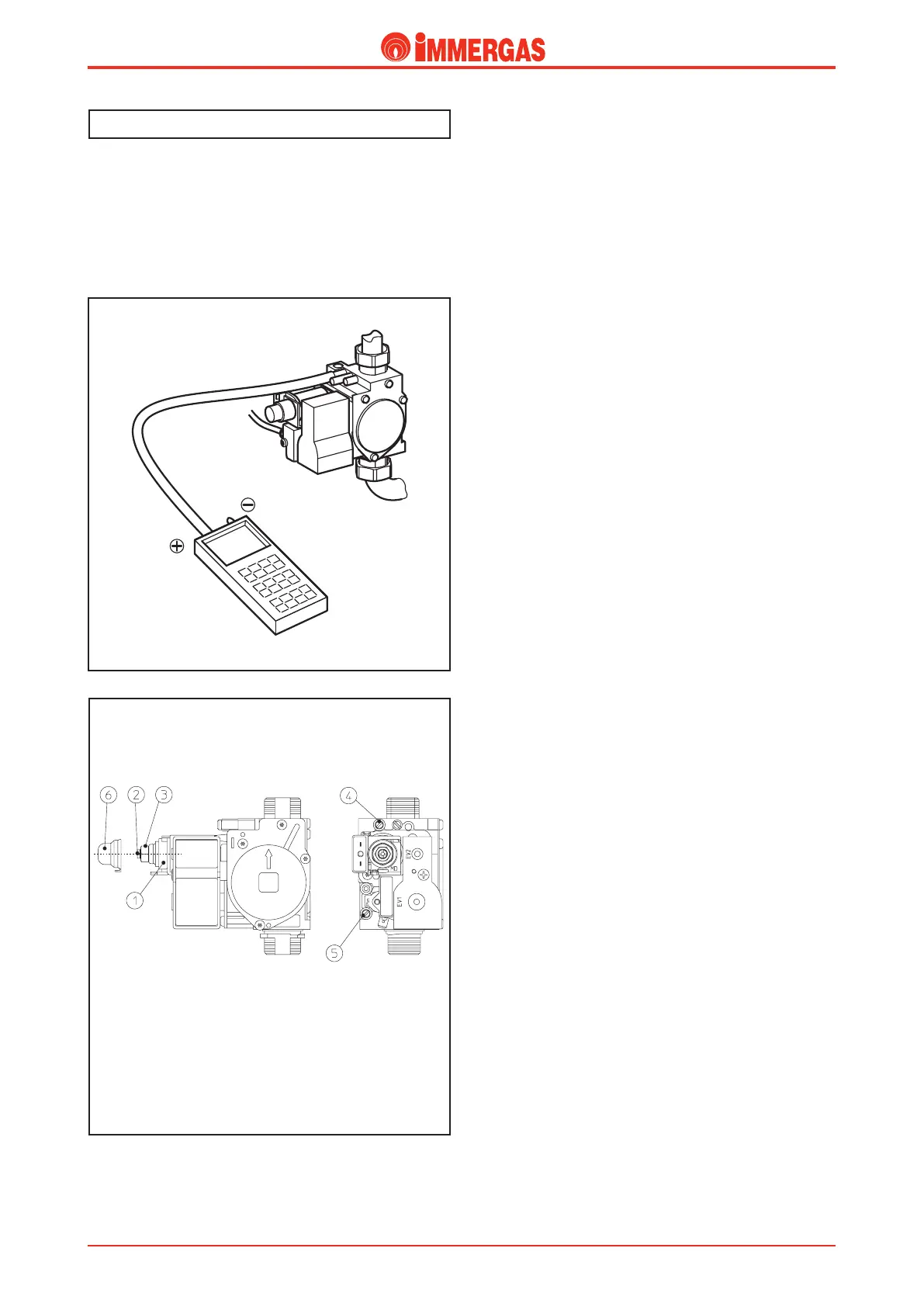

e measurements are taken using a dierential manometer,

whose pressure point is connected to the vas valve outlet (4)

(see gure).

Key:

1 - Coil

2 - Minimum power adjustment screws

3 - Maximum power adjustment nut

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection hood

SIT 845 Valve

SIT 845 Gas Valve

Maximum pressure adjustment

Draw DHW after having positioned the temperature dial on

maximum.

Act in a clockwise direction on the brass nut (3) to increase

the pressure to the burner and in a clockwise direction to

decrease it.

Minimum pressure adjustment

(to be carried out after adjusting the maximum pressure)

After disconnecting the power supply from the modulation

coil, turn the screw clockwise (2) to increase the pressure in

the burner and counter-clockwise to reduce it.

Gas transformation

e adaptation to the type of gas dierent to that for which

the boilers are prepared as per standard is performed using the

relevant kit (methane or LPG).

e transformation consists in replacing the nozzles of the

burner and selecting the parameter for the type of gas (G1)

on the boiler push button panel; then select (nG) for Methane

or (lG) for L.P.G.

e maximum and minimum DHW pressures are adjusted

on the gas valve in the manner described above.

e adjustments of the minimum and maximum outputs in

CH mode can be set using parameters (see integrated P.C.B.

functioning).

e ignition pressure for the burner can be adjusted and

set using the "Ignition Output" (G2) parameter with the

same value as "Minimum heating output" (see Operating the

integrated P.C.B.).

Loading...

Loading...