14

3-2

5

1

2

6

5

4

3

4

4

5

11

7

7

7

12

12

7

13

13

11

5

7

4

10

10

10

10

9

8

INSTALLATORUSER

MAINTENANCE TECHNICIAN

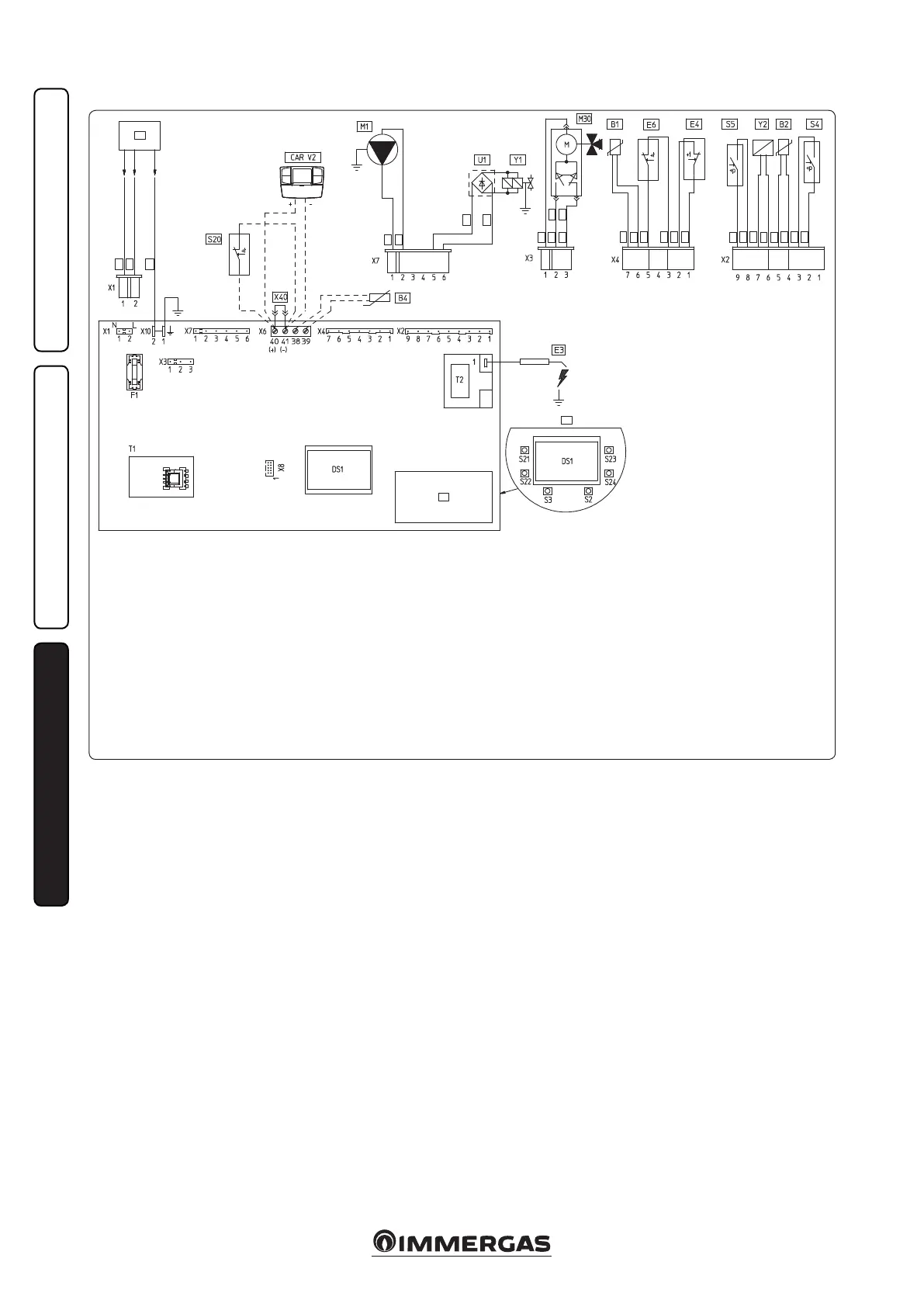

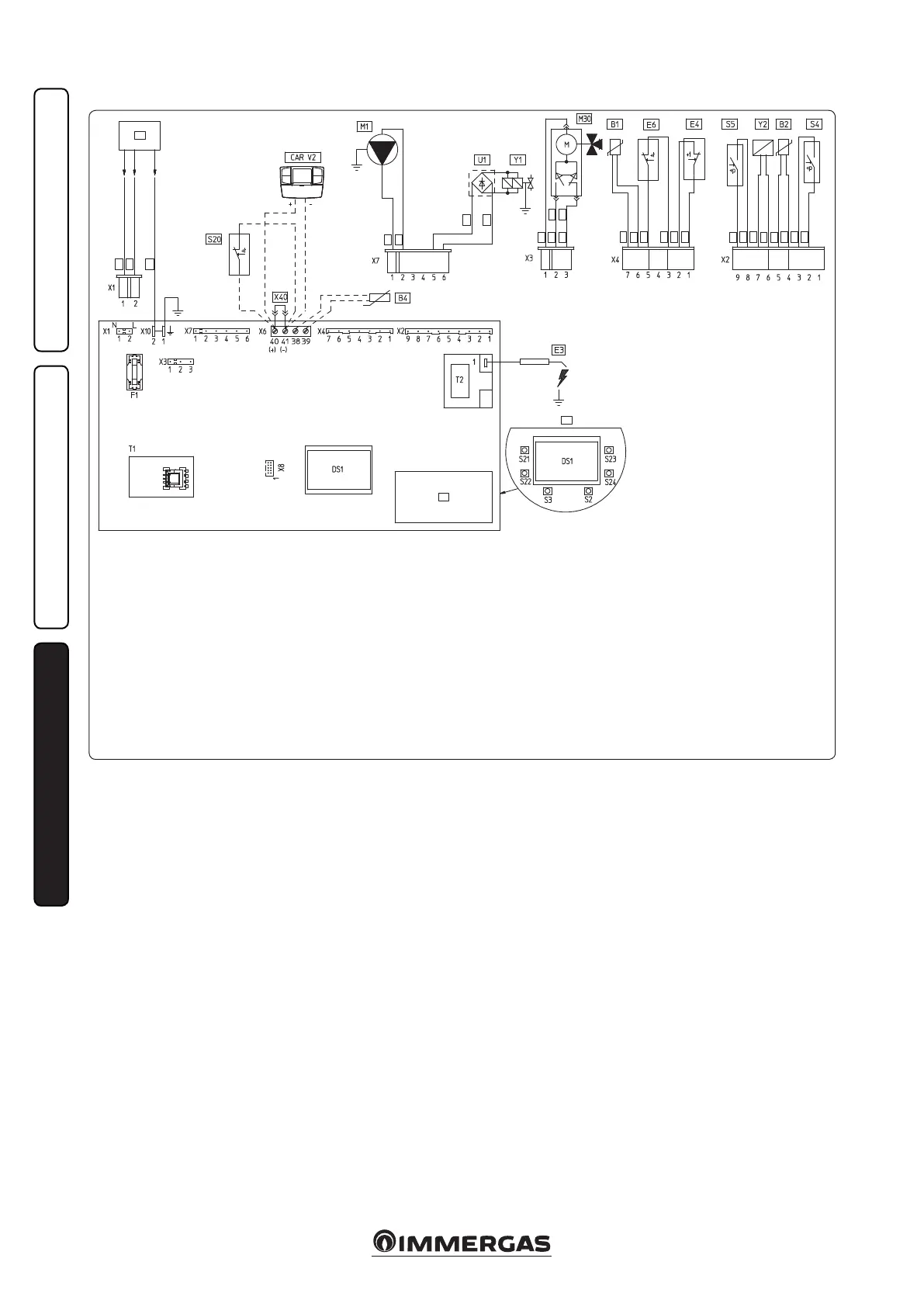

3.2 WIRING DIAGRAM.

Key:

B1 - Flow probe

B2 - Domestic hot water probe

B4 - External probe

CAR V2 - Comando Amico Remoto remote

control Version 2 (optional)

DS1 - Display

E3 - Ignition and detection electrodes

E4 - Safety thermostat

E6 - Flue safety thermostat

F1 - Phase fuse

M1 - Boiler pump

M30 - ree-way valve

S2 - Selector switch functioning

S3 - Reset block key

S4 - Domestic hot water ow switch

S5 - System pressure switch

S20 - Room thermostat (optional)

S21 - Domestic hot water temperature

increase key

S22 - Domestic hot water temperature

decrease key

S23 - Heating temperature increase key

S24 - Heating temperature reduce key

e boiler is designed for application of a room

thermostat (S20), an On/O room chronother-

mostat, a program timer or a Comando Amico

Remoto remote control

V2

(CAR

V2

). Connect

to clamps 40 - 41 eliminating the jumper X40,

paying attention not to invert the polarity if the

CAR

V2

is installed.

e connector X8 is used for the connection

of the Virgilio Palmtop in the microprocessor

soware updating operation.

3.3 TROUBLESHOOTING.

N.B.: maintenance interventions must be car-

ried out by an authorised rm (e.g. Technical

Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing eciency of gas intake

circuit.

- Irregular combustion (red or yellow ame).

When the burner is dirty or the boiler lamellar

pack is blocked. Clean the burner or the boiler

lamellar pack.

- Frequent interventions of the over heat-

ing safety thermostat. It can depend on

the lack of water in the boiler, little water

circulation in the system or blocked pump.

Check on the manometer that the sys-

tem pressure is within established limits.

Check that the radiator valves are not closed

and also the functionality of the pump.

- e boiler produces condensate. is can be

caused by obstructions of the chimney or ues

with height or section not proportioned to the

boiler. It can also be determined by function-

ing at boiler temperatures that are excessively

low. In this case, make the boiler run at higher

temperatures.

- Frequent interventions of the ue safety ther-

mostat is can be caused by obstructions in

the ue gas circuit. Check the ue. e ue

may be obstructed or by height or section

not suitable for the boiler. Ventilation may be

insucient (see room ventilation point).

- Presence of air in the system. Check opening

of the hood of the special air vent valve (Fig.

1-7). Make sure the system pressure and expan-

sion vessel pre-charge values are within the set

limits; the pre-charge value for the expansion

vessel must be 1.0 bar, and system pressure

between 1 and 1.2 bar.

- Ignition block and Chimney block. (See par.

2.6 and 1.5 electric connection).

T1 - Low voltage feeder

T2 - Switch-on transformer

U1 - Rectier inside the gas valve

connector (Only available on

Honeywell gas valves)

X40 - Room thermostat jumper

Y1 - Gas valve

Y2 - Gas valve modulator

1 - User interface

2 - N.B.: e user interface is on

the welding side of the boiler

board

3 - 230 Vac 50Hz power supply

4 - Blue

5 - Brown

6 - Yellow/Green

7 - Black

8 - (DHW)

9 - (central heating)

10 - Grey

11 - White

12 - Red

13 - Green

Loading...

Loading...