7

1-6

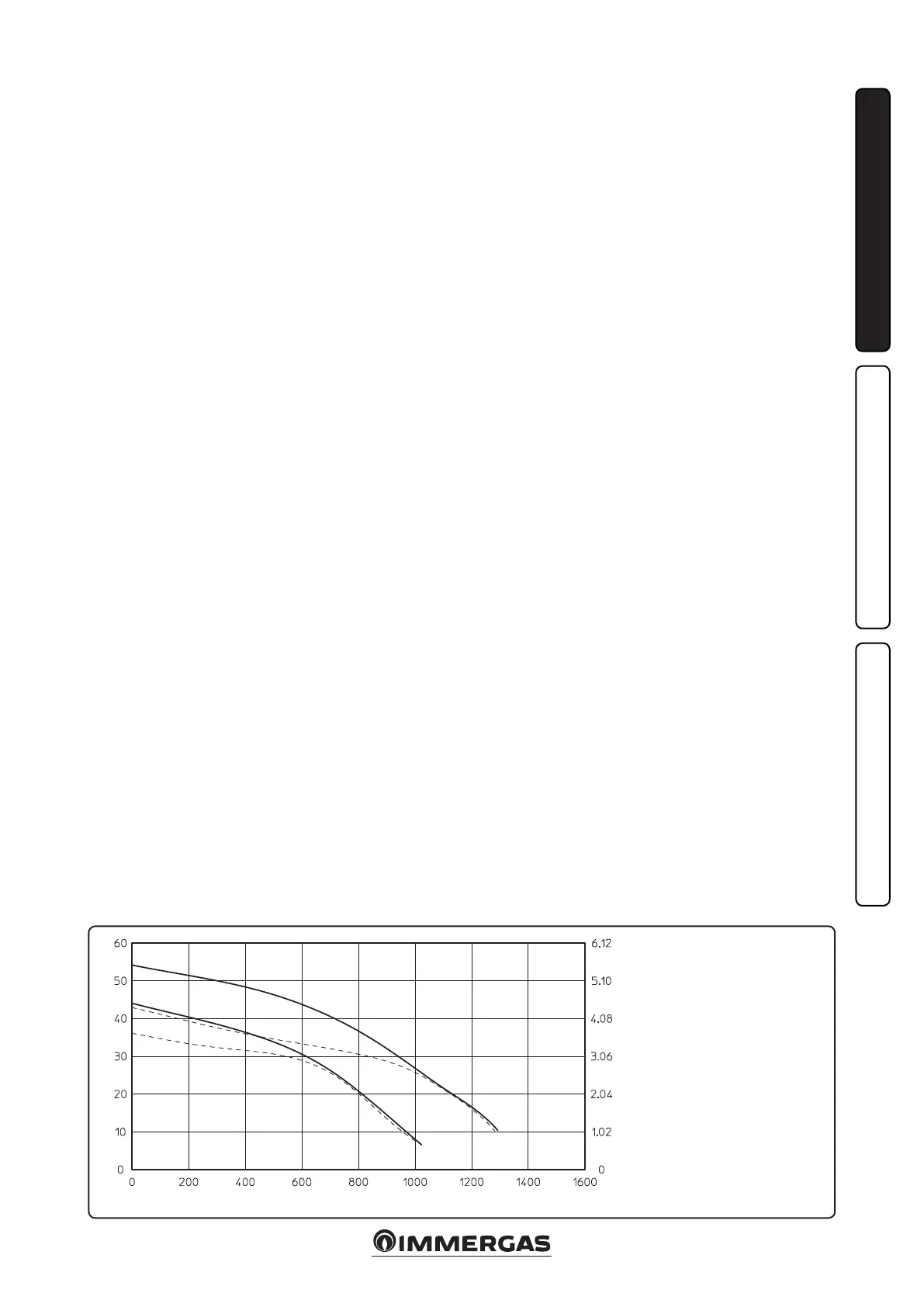

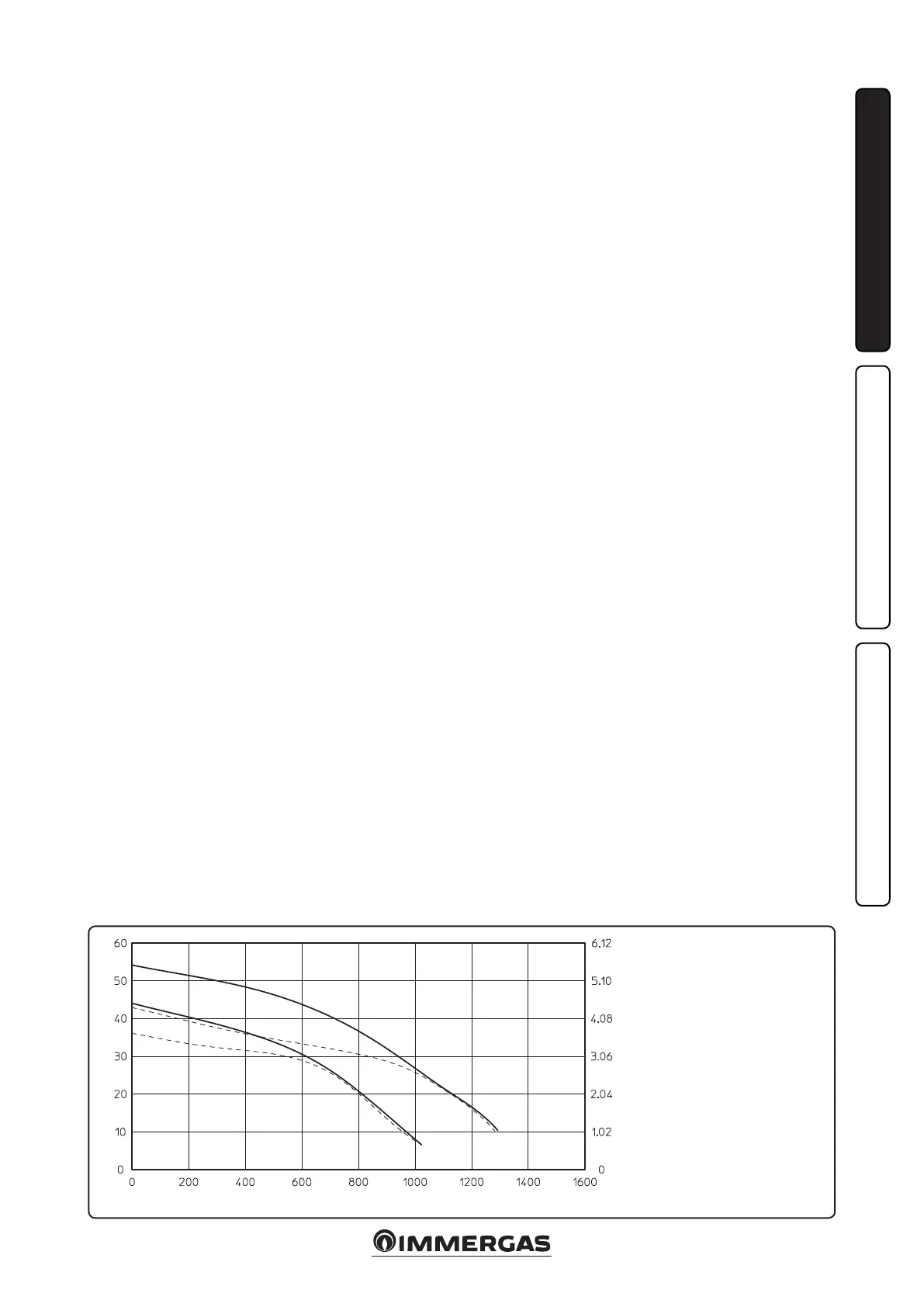

A

B

C

D

INSTALLATORUSER

MAINTENANCE TECHNICIAN

1.11 SYSTEM FILLING.

Once the boiler is connected, ll the system via

the lling valve (Fig. 2-2). Filling is performed

at low speed to ensure release of air bubbles in

the water via the boiler and heating system vents.

e boiler has a built-in automatic venting valve

on the circulator. Open the radiator vent valves.

Close radiator vent valves only when water es-

capes from them.

Close the lling valve when the boiler manometer

indicates approx. 1.2 bar.

N.B.: during these operations start up the cir-

culation pump at intervals, acting on the main

switch positioned on the control panel. Vent the

circulation pump by loosening the front cap and

keeping the motor running.

Tighten the cap aer the operation.

1.12 GAS SYSTEM STARTUP.

To start up the system, make reference to the

Standard.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specications.

1.13 BOILER START UP IGNITION.

For issue of the envisioned Declaration of Con-

formity, the following must be performed for

boiler start-up (the following operations must

only be performed by an authorised company

and only in the presence of sta):

- check that the internal system is properly sealed

according to specications

- make sure that the type of gas used corresponds

to boiler settings;

- check that there are external factors that may

cause the formation of fuel pockets;

- switch the boiler on and check correct ignition;

- make sure that the gas ow rate and relevant

pressure values comply with those given in the

manual (par. 3.18);

- check the correct ventilation of the rooms;

- check the existing draught during normal

functioning of the appliance, e.g. a draught

gauge positioned at the exit of the appliance

Total head available to the system.

Total head (m H

2

O)

Flow rate (l/h)

Head (kPa)

A = Head available to the

system at maximum speed

with by-pass excluded.

B = Head available to the

system at maximum speed

with by-pass inserted.

C = Head available to the

system at second speed with

by-pass excluded.

D = Head available to the

system at second speed with

by-pass inserted.

combustion products;

- check that there is no backow of combustion

products into the room, even during function-

ing of fans;

- ensure that the safety device is engaged in the

event of gas supply failure and check activation

time;

- check activation of the main switch located

upstream from the boiler.

e boiler must not be started up even if only

one of the checks should be negative.

1.14 CIRCULATION PUMP.

e Mini Nike 24 3 E series boilers are supplied

with a built-in circulation pump with 3-posi-

tion electric speed control. e boiler does not

operate correctly with the circulation pump on

rst speed. To ensure optimal boiler operation,

in the case of new systems (single pipe and

module) it is recommended to use the pump

at maximum speed. e pump is already tted

with a condenser.

Pump release. If, aer a prolonged period of

inactivity, the circulation pump is blocked,

unscrew the front cap and turn the motor sha

using a screwdriver. Take great care during this

operation to avoid damage to the motor.

By-pass regulation (part. 20 Fig. 1-7). If neces-

sary, the by-pass can be regulated according to

system requirements from a minimum (by-pass

excluded) to a maximum (by-pass inserted)

represented by the graphics (Fig. 1-6).

Make the regulation using a at head screw-

driver, turn clockwise and insert the by-pass,

anti-clockwise it is excluded.

1.15 KITS AVAILABLE ON REQUEST.

• System shut o valves kit. e boiler is designed

for installation of system interception cocks

to be placed on ow and return pipes of the

connection assembly. is kit is particularly

useful for maintenance as it allows the boiler to

be drained separately without having to empty

the entire system.

• Polyphosphate dispenser kit. e polyphos-

phate dispenser reduces the formation of lime-

scale and preserves the original heat exchange

and domestic hot water production conditions.

e boiler is prepared for application of the

polyphosphate dispenser kit.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Loading...

Loading...