16

4

3

2

1

5

6

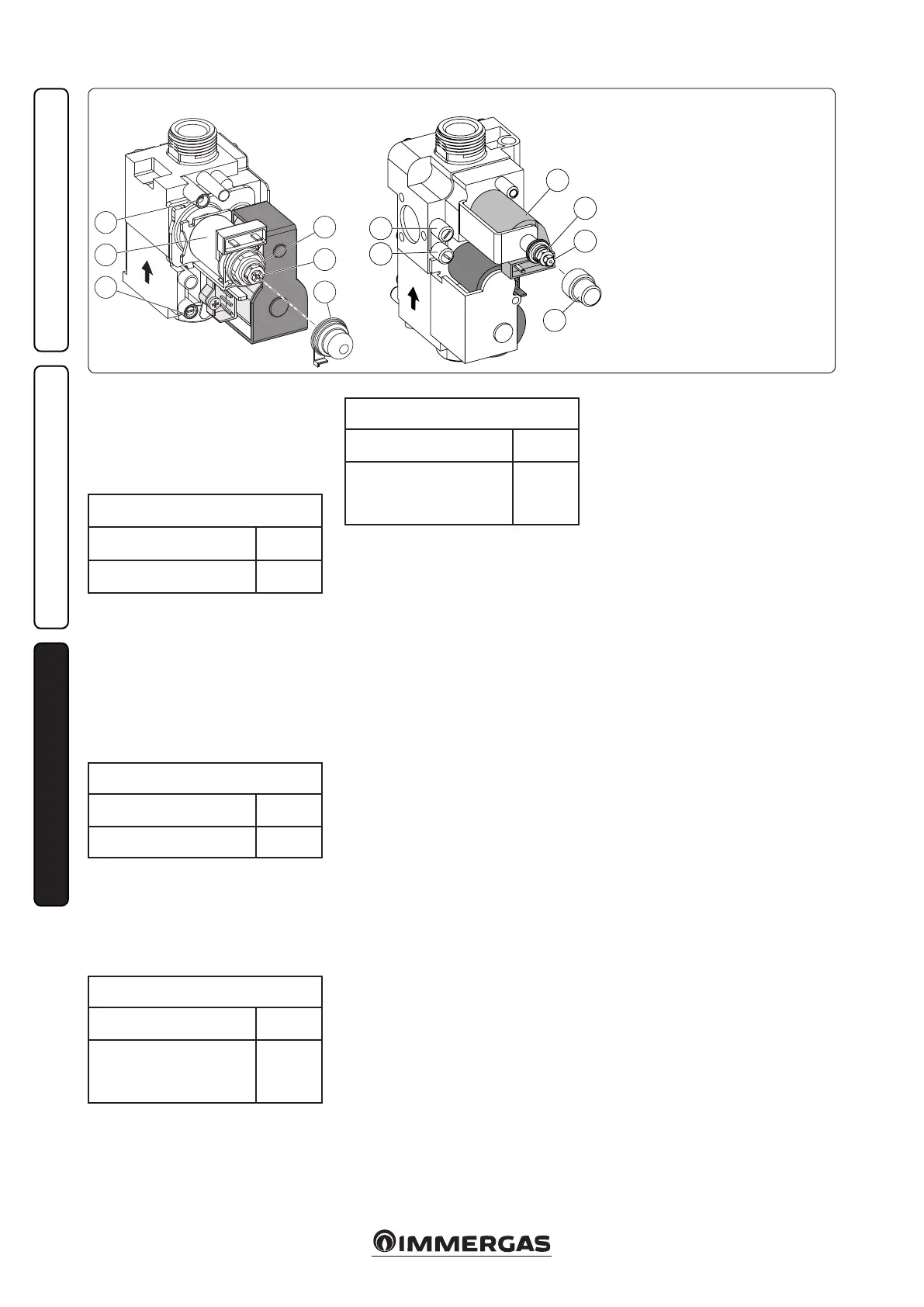

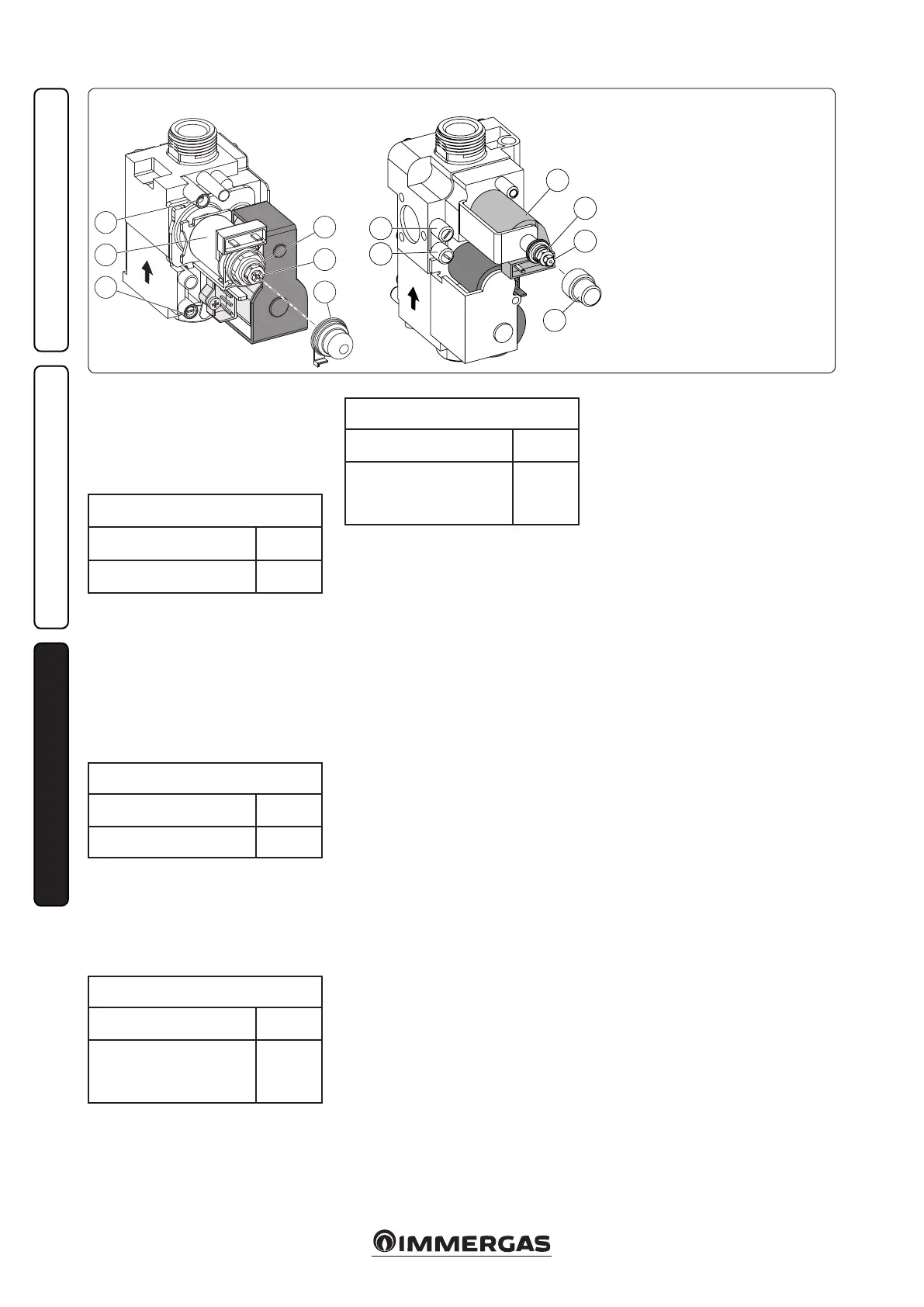

3-3

4

3

2

1

6

5

INSTALLATORUSER

MAINTENANCE TECHNICIAN

Heating switch-on delay request from room

thermostat and remote control. e boiler is

set to switch-on immediately aer a request. In

the case of particular systems (e.g. area systems

with motorised thermostatic valves etc.) it could

be necessary to delay switch-on.

Heating switch-on delay request from

room thermostat and remote control (P8)

Range of values which can

be set

Parameter

0 - 20 (0 - 10 minutes)

(01 equals 30 seconds)

0

(0’)

DHW ignition delay. e boiler is set to switch-

on immediately aer a request. for DHW In

the case of coupling with solar storage tanks

positioned upstream from the boiler, it is pos-

sible to compensate the distance of the storage

tank in order to allow the hot water to reach the

utility, setting the necessary time and therefore

verifying that the water is hot enough (see Par.

Solar panels coupling).

Solar mode (P9)

Range of values which can

be set

Standard

setting

0 - 20 seconds 0

Gas type selection. e setting of this function

is used to adjust the boiler in order to function

with the correct type of gas.

To access this regulation, once having entered the

programming mode, press the button (2) for 4

seconds. To exit, press button (2) again 4seconds.

Gas type selection (G1)

Range of values which can

be set

Standard

setting

nG - Methane

lG - LPG

Ci - China

e same

as the type

of gas be-

ing used

Ignition power (G2)

Range of values which can

be set

Standard

setting

0 - 70 %

Set

according

to factory

inspection

3.6 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a dierent gas

type to that specied on the data plate, request

the relative conversion kit for quick and easy

conversion.

e gas conversion operation must be carried

out by an authorised rm (e.g. Technical As-

sistance Service).

To convert to another type of gas the following

operations are required:

- remove the voltage from the appliance;

- replace the main burner injectors, making sure

to insert the special seal rings supplied in the

kit, between the gas manifold and the injectors;

- apply voltage to the appliance;

- use the boiler push button control panel to

select the gas parameter type (G1) and select

(Ng) in case of Methane supply or (Lg) in the

case of LPG;

- adjust the boiler nominal heat output;

- adjust the boiler minimum heat power;

- adjust the boiler nominal heat output in heating

phase;

- adjust (eventually) the maximum heating

power;

- seal the gas ow rate regulation devices (if set-

tings are modied);

- aer completing conversion, apply the sticker,

present in the conversion kit, near to the data-

plate. Using an indelible marker pen, cancel the

data relative to the old type of gas.

ese adjustments must be made with reference

to the type of gas used, following that given in

the table (par. 3.18).

3.7 CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

Aer making sure that conversion was carried

out with a nozzle of suitable diameter for the

type of gas used and the settings are made at the

correct pressure, check that:

- there is no ame in the combustion chamber

- the burner ame is not too high or low and that

it is stable (does not detach from burner)

- the pressure testers used for calibration are

perfectly closed and there are no leaks from

the gas circuit.

N.B.: all boiler setting operations must be car-

ried out by an authorised rm (e.g. Technical

Assistance Service). Burner adjustment must

be carried out using a dierential “U” or digital

type manometer connected to the gas valve outlet

pressure point (part.4 Fig.3-3), keeping to the

pressure value given in the table (Par. 3.18) ac-

cording to the type of gas for which the boiler

is prepared.

SIT 845 GAS valve

Key:

1 - Coil

2 - Minimum power adjustment nut

3 - Maximum power adjustment nut

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection hood

VK 4105 M GAS valve

Loading...

Loading...