Slew Drives

Installation and commissioning

27

5.2.5 Tightening bolts with a torque wrench

Normally the mounting bolts are adequately secured through

correct pretension.

WARNI

WARNIWARNI

WARNING

NGNG

NG

Do not use impact screwdrivers. Using an impact

screwdriver may cause impermissible deviations between

the bolt tightening forces. Failure of the bolted union with

the mounting structure may cause severe personal injury

or material damage.

IMPORTANT

If there are shock loads or vibration additional screw-

locking devices may be necessary. In this case use Loctite

or Nord-Lock® bolt lock washers.

Do not use split rings, spring washers, etc.

Do not reuse bolts, nuts, and washers, etc.

Only use hardened and tempered washers.

Adjust the limit torque in accordance with bolt size and quality.

Use a precisely indicating torque wrench.

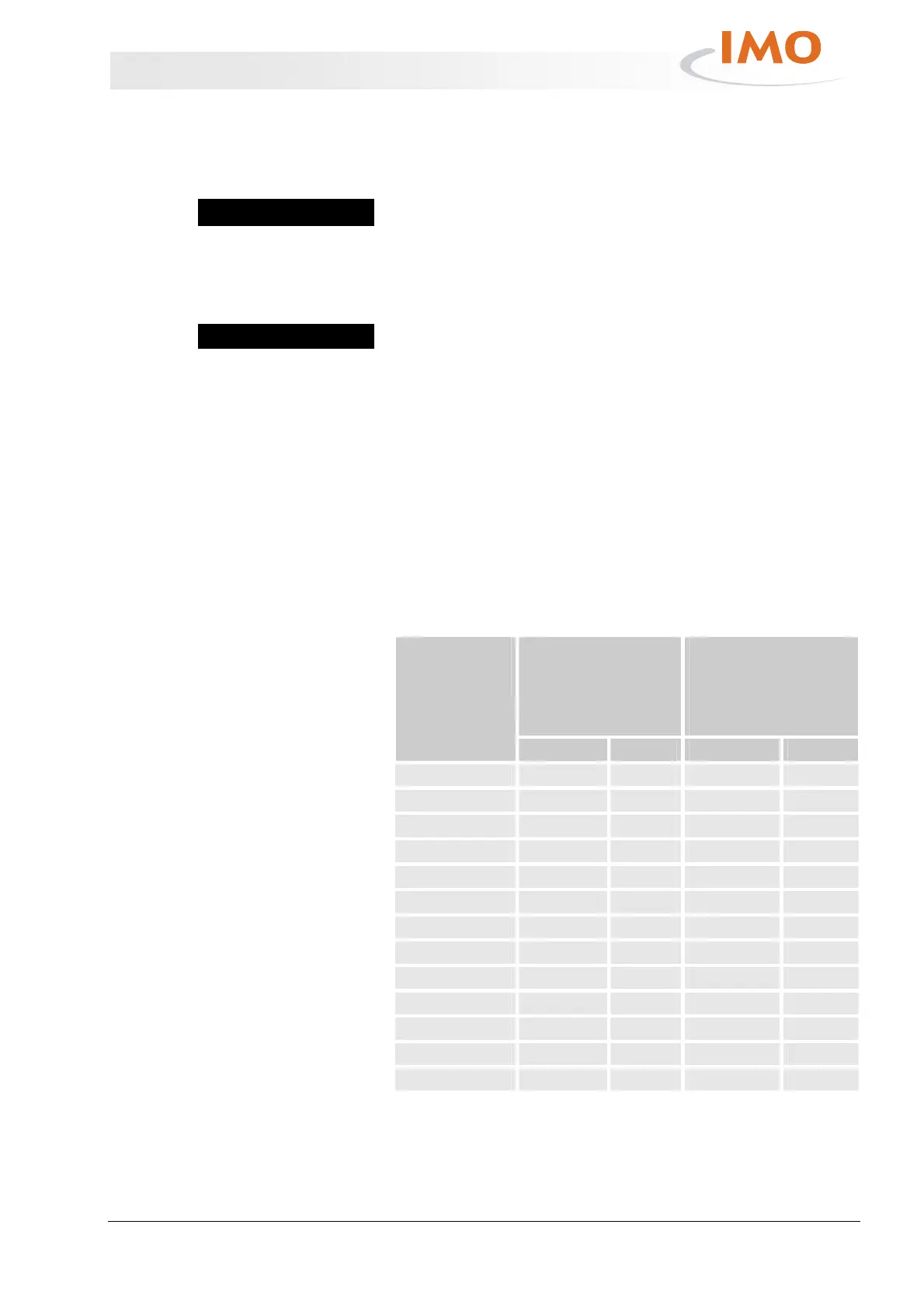

Tightening torques and bolt tightening forces for metric

coarse-pitched thread in accordance with DIN 13 when

using a torque wrench:

Tightening torque

M

A

1)

Strength class 10.9

in

Mounting pretension

force

F

M

2)

Strength class 10.9

in

Mounting

bolt

dimensions

Nm ft-lbs kN lbs

M4 3.31 2.44 5.95 1338

M5 6.77 4.99 9.74 2190

M6 11.5 8.5 13.7 3080

M8 28.0 20.6 25.2 5665

M10 55.8 41.2 40.2 9037

M12 97.7 72.1 58.5 13151

M16 246 181 111 24954

M18 336 248 134 30124

M20 481 355 173 38892

M22 661 487 216 48559

M24 830 612 249 55977

M27 1230 907 328 73737

M30 1661 1225 398 89474

Tab. 8

1)

M

A

in accordance with VDI guideline 2230 (February 2003) for

µK=0.08 and µG=0.12

2)

F

M

in accordance with VDI guideline 2230 (February 2003) for

µG=0.12

Loading...

Loading...