Slew Drives

Maintenance

39

The specified values are valid for the following conditions:

Operating temperature on the slew drive < 70° C (158° F).

Circumferential speed < 0.5 m/s (1.64 ft/sec) for SP slew

drives.

Output speed < 5 rpm for WD slew drives.

Low to moderate load.

Comply with the instructions in the operating manual provided

by the manufacturer, for lubrication of optional intermediate

gear units, brakes, and motors.

If necessary re-lubricate permanent brakes. For this only use

the special grease SHELL RETINAX HDX2.

6.4 Maintenance tasks

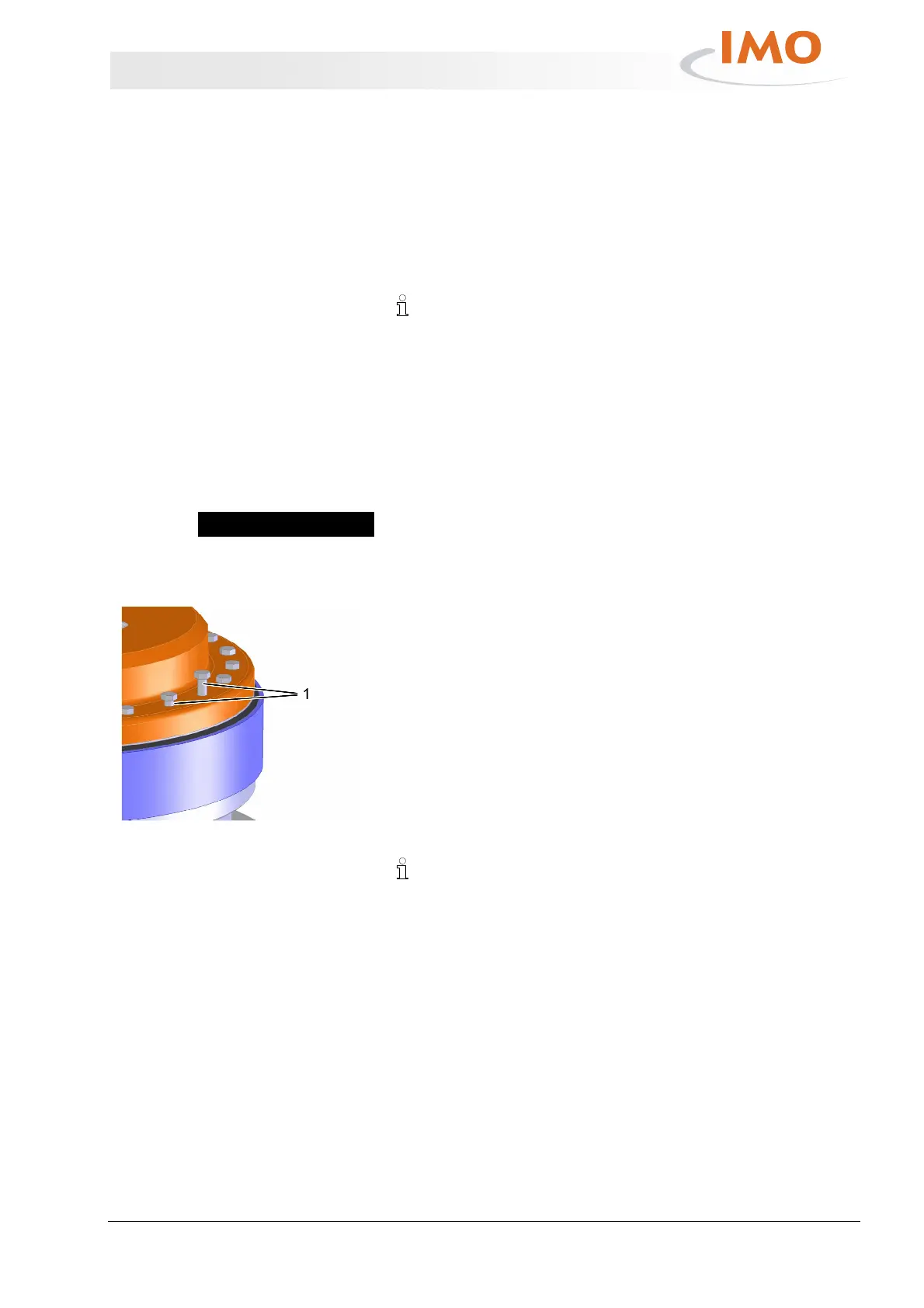

6.4.1 Inspecting the mounting bolts

IMPORTANT

To compensate for settling, the bolts must be retightened

with the prescribed tightening torque. Retightening must

be executed without exerting additional external stress on

the bolted union.

Fig. 25: Inspecting the mounting bolts

1 Detached bolt

Execution only by a specialist.

Special tools required:

Torque wrench

Hydraulic clamping fixture

Replace loose and detached bolts or nuts and washers with

new bolts, nuts and washers.

Use the same bolt size and bolt quality.

If a hydraulic clamping fixture was used to tighten the bolts,

then a hydraulic clamping fixture must also be used to check

the bolt pretension. Always use the same tightening procedure

as specified for installation of the slew drive when checking the

bolted union.

6.4.2 Checking the tilting clearance

Wear in the raceway system results in an increase in tilting

clearance. Consequently it is necessary to check the tilting

clearance in accordance with the maintenance intervals ( section

6.3 "Maintenance schedule").

CAUTION!

CAUTION!CAUTION!

CAUTION! If the maximum permissible tilting clearance

increase is reached, then the system must be brought to a

standstill and the slew drive must be replaced

immediately, as safe operation can no longer be ensured.

Loading...

Loading...