Slew Drives

Installation and commissioning

30

2 – 4.5 UNC 1239 278538

2 1/4 – 4.5 UNC 1608 361493

2 1/2 – 4 UNC 1981 445347

2 3/4 – 4 UNC 2442 548984

Tab. 11

1)

F

M

for hydraulic bolt-tensioning cylinder pretensioned to 85% of

yield strength

5.3 Installing the slew drive

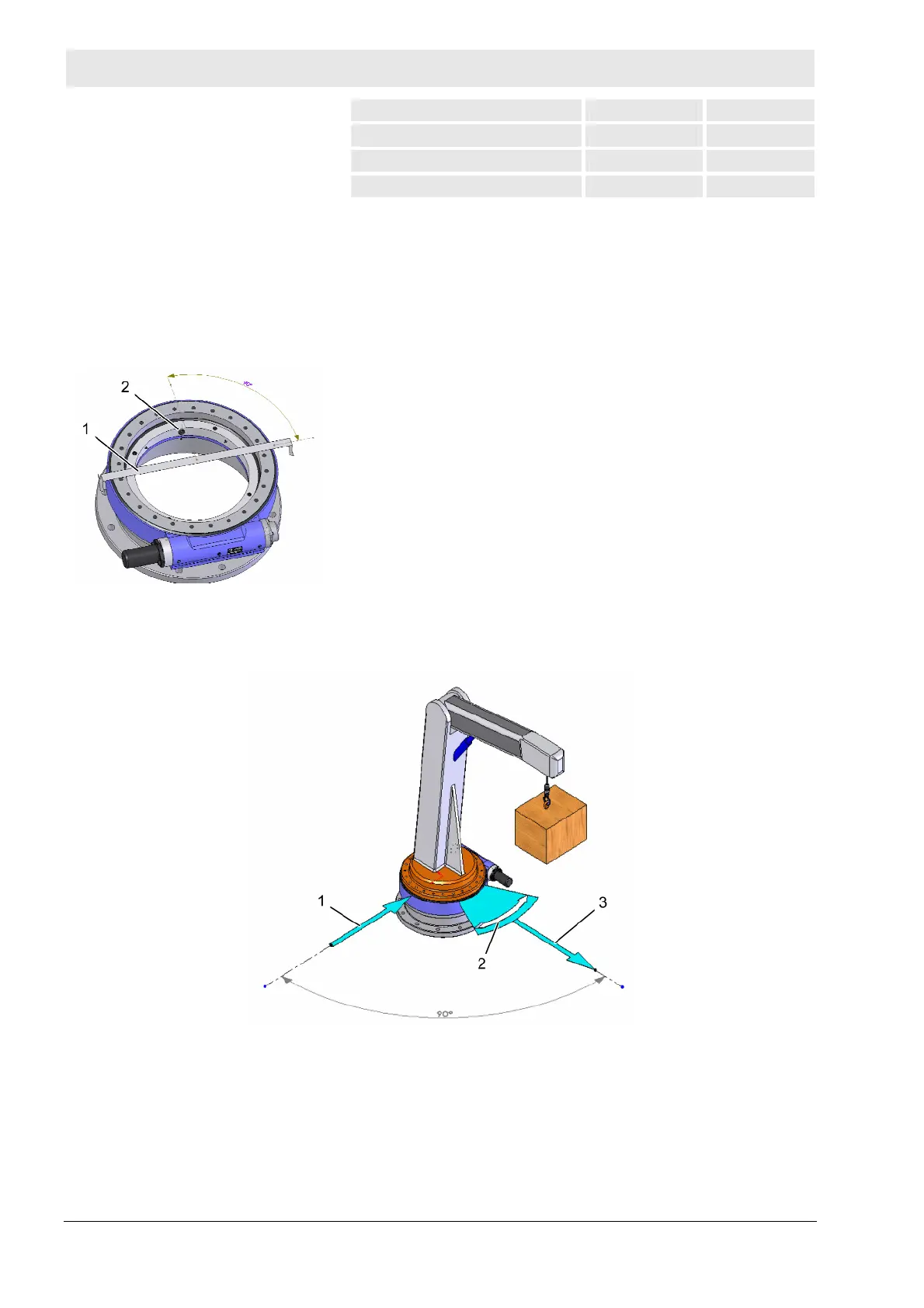

5.3.1 Hardness gap

Fig. 19: Hardness gap marking

The hardness gap occurs with the raceway hardening and is

located between the end and the beginning of the hardening.

For the WD-L series the hardness gap must be arranged with an

offset by 90° relative to the main load-carrying zone. The hardness

gap is marked by a filling plug or a stamped "S".

1 Main load-carrying zone

2 Filling plug or S-mark

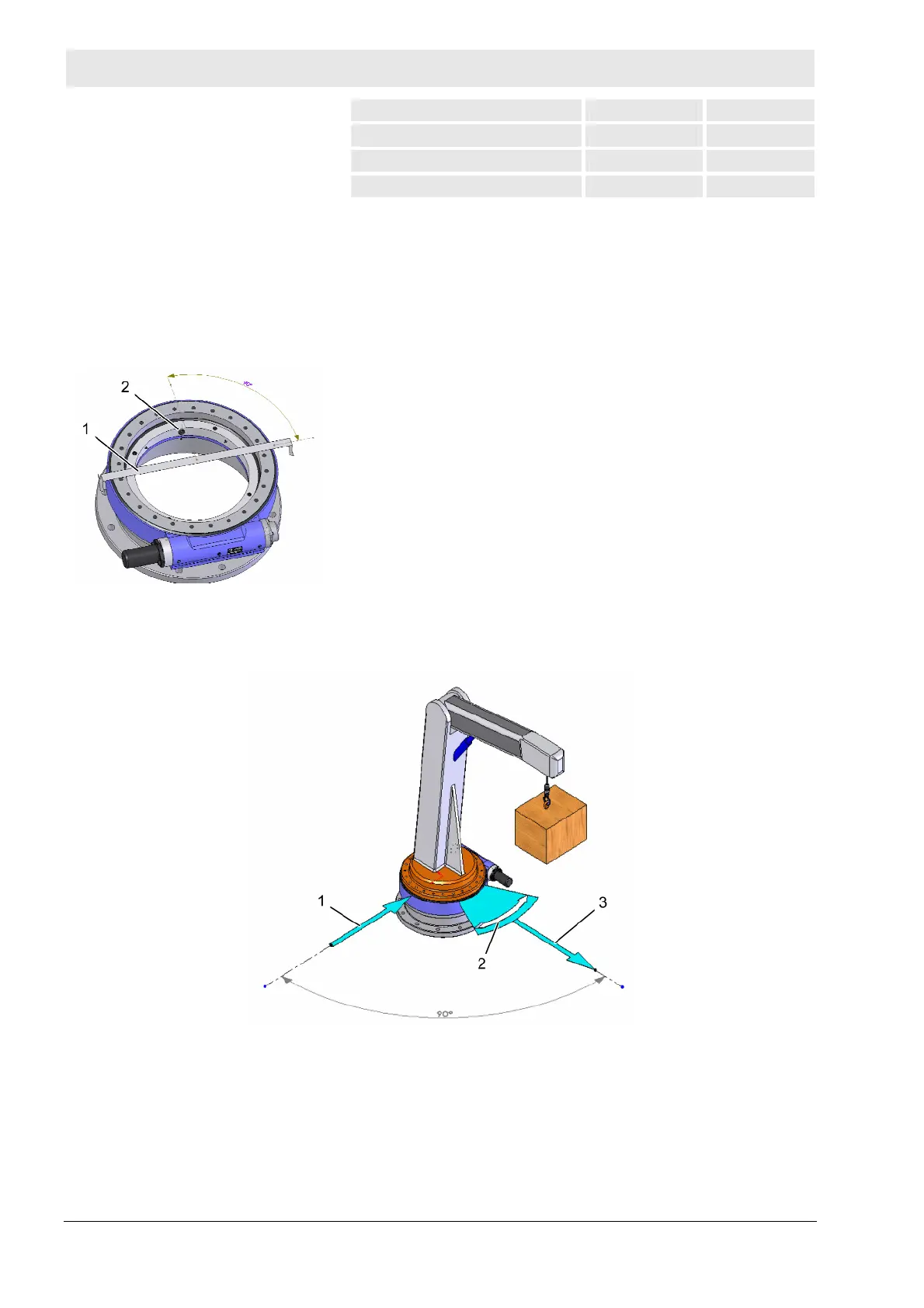

5.3.2 Positioning the slew drive

Fig. 20: Main load-carrying zone

1 Hardness gap

2 Main slewing range

3 Main load-carrying zone

1. Determine the main load-carrying zone.

The main load-carrying zone is that area of the slewing ring

that is subject to the highest load, taking all aggressive forces

and torques, and all occurring load cases into account.

Loading...

Loading...