Slew Drives

Installation and commissioning

28

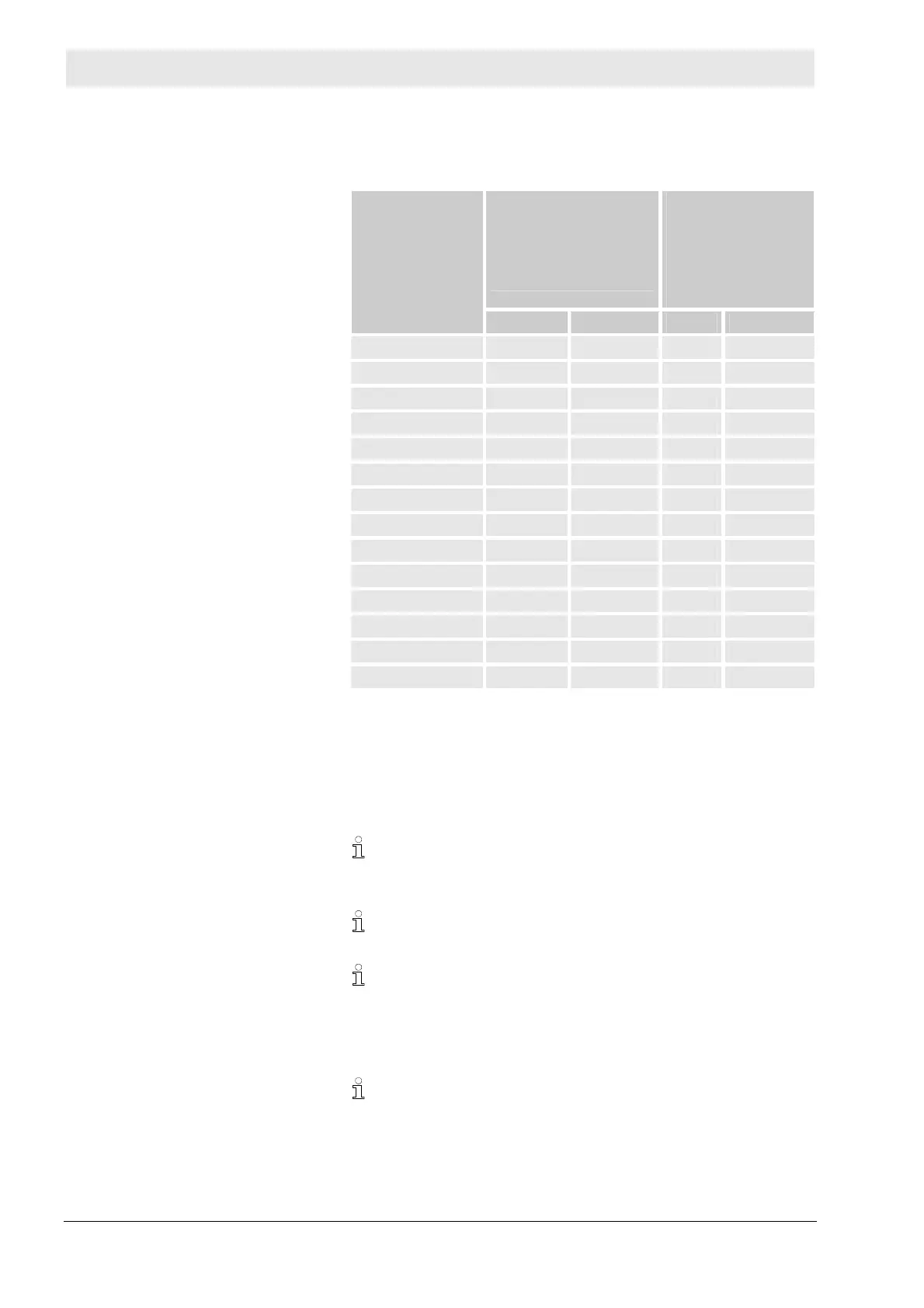

Tightening torques and bolt tightening forces for inch

thread in accordance with ANSI B1.1 when using a torque

wrench:

Tightening torque

M

A

1)

Strength class

Grade 8

in

Mounting

pretension force

F

M

2)

Strength class

Grade 8

in

Mounting bolt

dimensions

Nm ft-lbs kN lbs

0.1900 – 24 UNC

4.80 3.54 7.15 1607

0.2160 – 24 UNC

7.69 5.67 10.1 2271

1/4 – 20 UNC 11.7 8.6 13.2 2967

5/16 – 18 UNC 24.4 18.0 22.1 4968

3/8 – 16 UNC 43.7 32.2 33.0 7419

7/16 – 14 UNC 70.1 51.7 45.4 10206

1/2 – 13 UNC 108 80 61.0 13713

9/16 –12 UNC 156 115 78.6 17670

5/8 – 11 UNC 216 159 97.8 21986

3/4 – 10 UNC 386 285 146 32822

7/8 – 9 UNC 625 461 202 45411

1 – 8 UNC 938 692 266 59799

1 1/8 – 7 UNC 1328 979 334 75086

1 1/4 – 7 UNC 1889 1393 428 96218

Tab. 9

1)

M

A

in accordance with VDI guideline 2230 (February 2003) for

µK=0.08 and µG=0.12

2)

F

M

in accordance with VDI guideline 2230 (February 2003) for

µG=0.12

For mounting bolts from M30 or 1 1/8 - 7 UNC use a hydraulic

bolt-tensioning cylinder ( chapter 5.2.6 "Tightening bolts with

a hydraulic bolt-tensioning cylinder").

When using bolts with fine-pitched thread or other bolt sizes or

qualities, please contact our customer service ( page 2).

For further information about bolts, please refer to the IMO

main catalogues.

5.2.6 Tightening bolts with a hydraulic bolt-tensioning cylinder

Comply with the instructions provided in the operating manual

for the hydraulic fixture! The operating manual for the hydraulic

bolt-tensioning cylinder specifies how the hydraulic pressure is

converted to the pretension force.

Loading...

Loading...