99903514: TELESCOPIC CRANE: 1-3 SECTION 1: OPERATION

For maximum safety during work near

powerlines, adhere to the following guidelines:

•During windy conditions, allow additional

clearance.

•Do not rely on cage-type boom guards, insulat-

ing links, or proximity warning devices for safety.

Adhere to the required distances listed in Figure

A-2.

•Contact the utility company before beginning

work near powerlines.

•Always assume overhead lines to be ener-

gized.

•Avoid transporting a crane over uneven terrain.

•When using rope to steady a load or restrain

spinning of the load, be aware that rope will also

conduct electricity, especially if wet or damp.

•Reduce operating speed when in close proxim-

ity to powerlines in order to allow the operator

more reaction time.

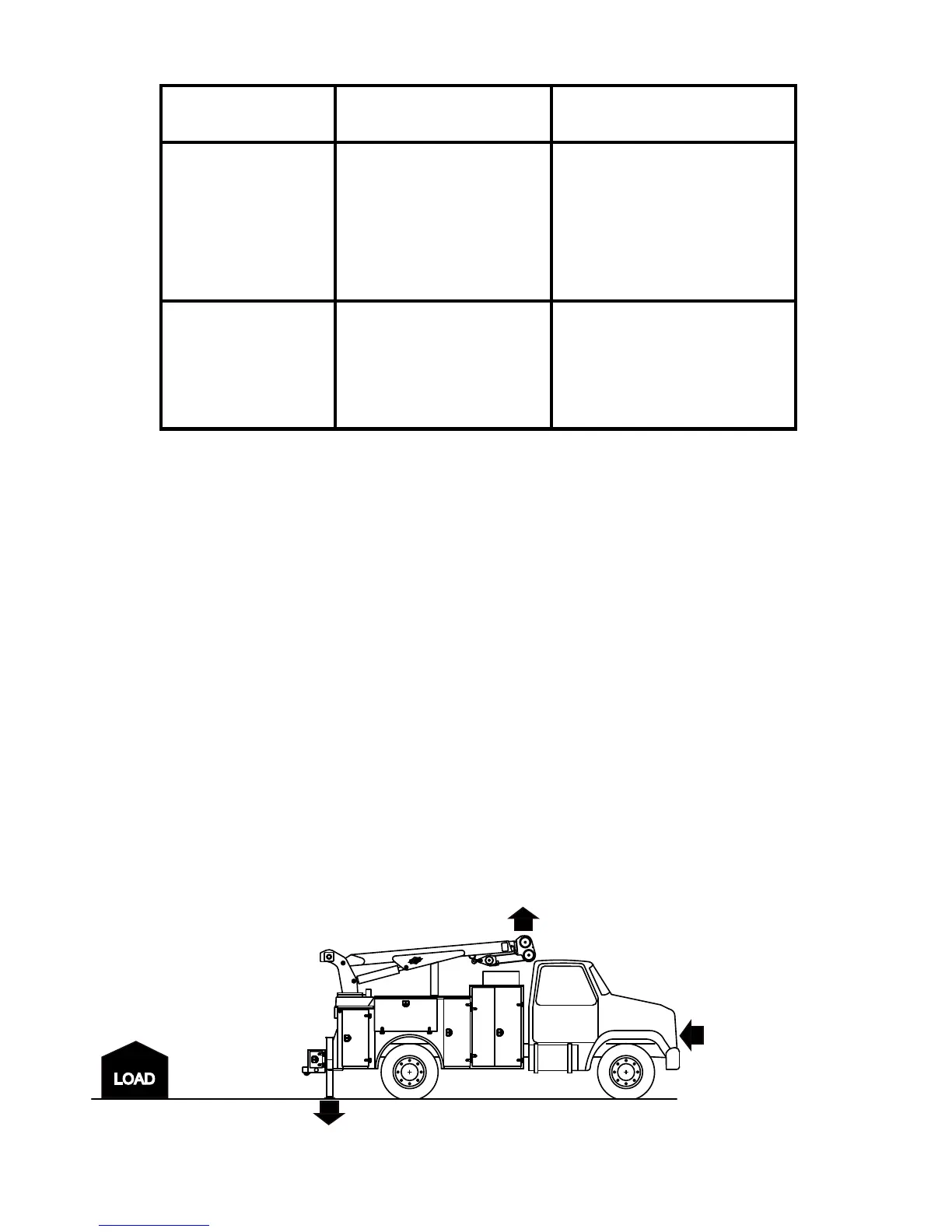

NORMAL VOLTAGE MINIMUM REQUIRED

kV (Phase to Phase) CLEARANCE Feet (meters)

OPERATION NEAR From 0 to 50 10 ( 3.05)

HIGH VOLTAGE From 50 to 200 15 ( 4.60)

POWERLINES From 200 to 350 20 ( 6.10)

From 350 to 500 25 ( 7.62)

From 500 to 750 35 (10.67)

From 750 to 1000 45 (13.72)

OPERATION IN From 0 to 0.75 4 ( 0.22)

TRANSIT WITH From 0.75 to 50 6 ( 0.83)

NO LOAD AND From 50 to 345 10 ( 3.05)

BOOM OR MAST From 345 to 750 16 ( 4.87)

LOWERED. From 750 to 1000 20 ( 8.10)

Figure A-2: Required Clearance of Cranes from Electrical Transmission Lines

IF ELECTRICAL CONTACT OCCURS:

1. Shut off all power.

2. Break contact of any person in contact with a

live conductor by using rubber hose, dry rope, or

dry wood. DO NOT attempt this unless you are

certain that all power is off.

3. Call 911 or the local emergency service.

4. Administer first aid.

5. Avoid the area around the crane, as high

voltage travelling through a crane will charge the

ground.

ELECTRICAL CONTACT FOLLOW-UP

1. Inspect and repair any equipment affected by

electrical contact.

2. Replace any wire rope which has had high

voltage contact.

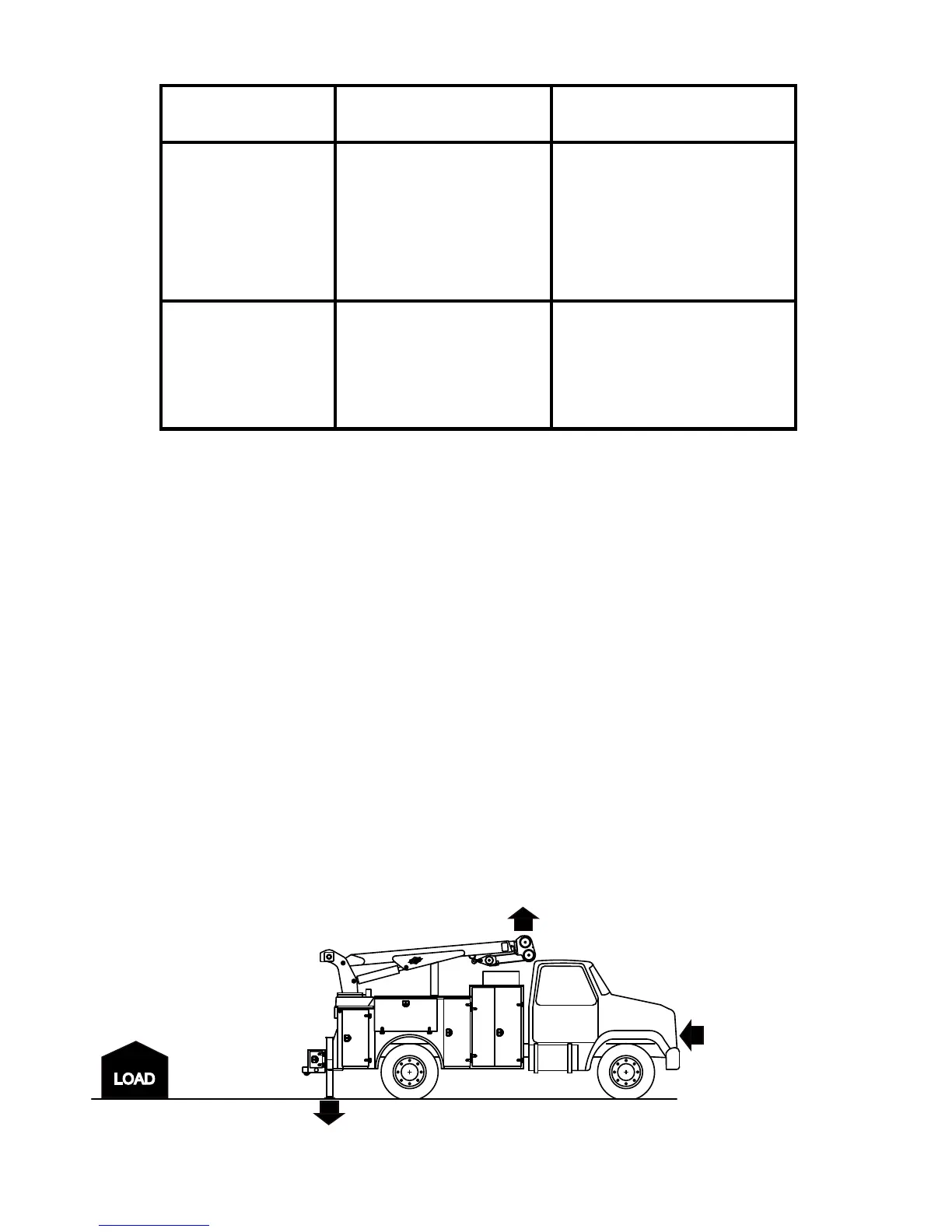

Figure A-3: Work Site Set-up

Outriggers fully out and down on

a firm and level surface.

Parking brake "ON."

Transmission in neutral.

No overhead obstructions.

No powerlines.

.

Load does not

exceed crane capacity.

20030115

Loading...

Loading...