99903514:TELESCOPIC CRANE: 4-7

SECTION 4: INSTALLATION

4.6 MODEL 1015 CRANE INSTALLA-

TION

CRANE INSTALLATION

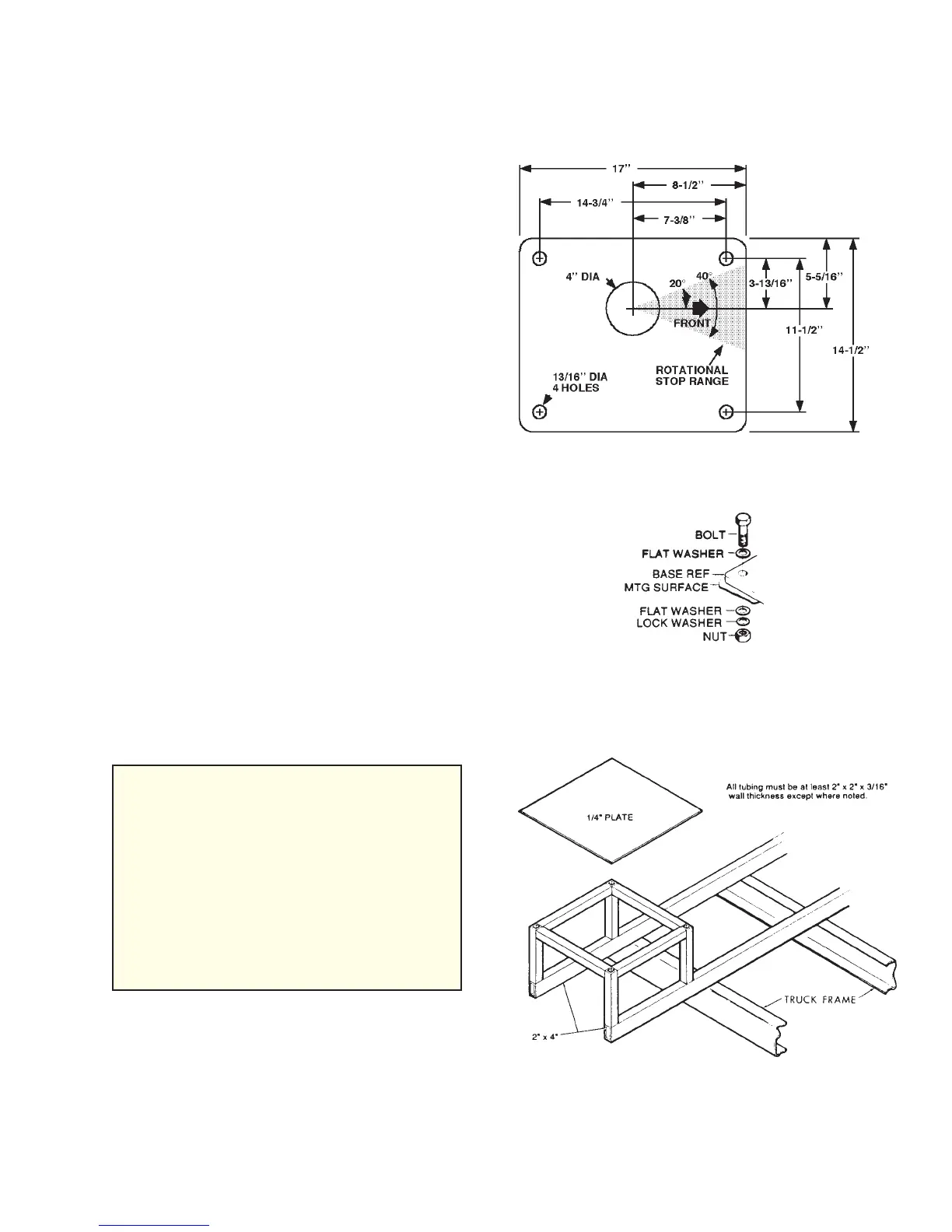

MOUNTING HOLE LAYOUT

REINFORCEMENT

MINIMUM CHASSIS SPECIFICATIONS

BODY STYLE Conventional

Cab

WHEELBASE 137” - 161”

CAB TO AXLE 60” - 84”

FRAME SECTION MODULUS 5.91 in³

RBM 212,760 in-lb

(based on 36,000 psi yield frame mat’l)

FRONT AXLE RATING 4000 lb

REAR AXLE RATING 7500 lb

CRANE INSTALLATION

The crane requires a mounting space of at

least 14-1/2" wide by 17" long. If necessary,

the truck body can be reinforced to give

sufficient strength to support the crane in its

operating condition. Locate and drill the four

13/16" holes (see Mounting Hole Layout

drawing). Use a pilot drill first and then the 13/

16" drill. Cut the 4" diameter hole with a saw

after starting with a drill. Deburr all holes. Lift

the crane into position on the body. Use a

lifting device capable of supporting the crane -

650 lbs (295 kg).

Install the bolts, lockwashers, flat washers

and nuts to secure the crane to the chassis

(see Crane Installation drawing). Torque the

bolts to 200 ft. lbs. (27.66 kg-m).

NOTE

IN ADDITION TO THESE SPECIFICA-

TIONS, A HEAVY-DUTY BATTERY AND

ALTERNATOR ARE REQUIRED. IT IS

RECOMMENDED THAT THE VEHICLE

HAVE POWER STEERING AND DUAL

REAR WHEELS.

IMT RECOMMENDS ADHERENCE TO

THE UPPER LIMIT OF THESE SPECIFI-

CATIONS FOR BEST SYSTEM PER-

FORMANCE.

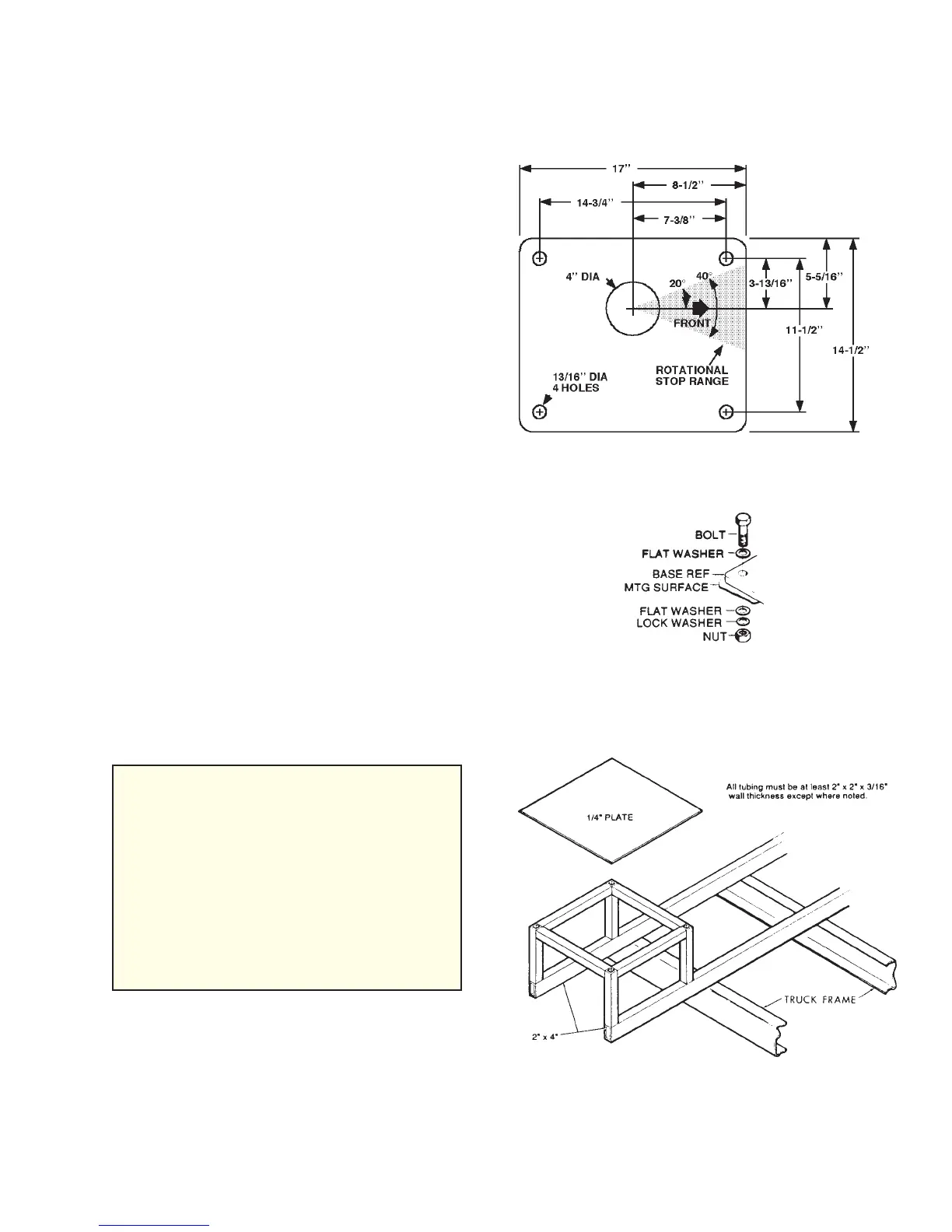

BODY REINFORCEMENT

If, after talking with the factory, it has been

determined that the body will not support the

crane with the full, rated load, the body can be

reinforced as shown. Use 1/4" fillet welds and

an AWS qualified welder.

20030115

Loading...

Loading...