99903514:TELESCOPIC CRANE: 4-4

SECTION 4: INSTALLATION

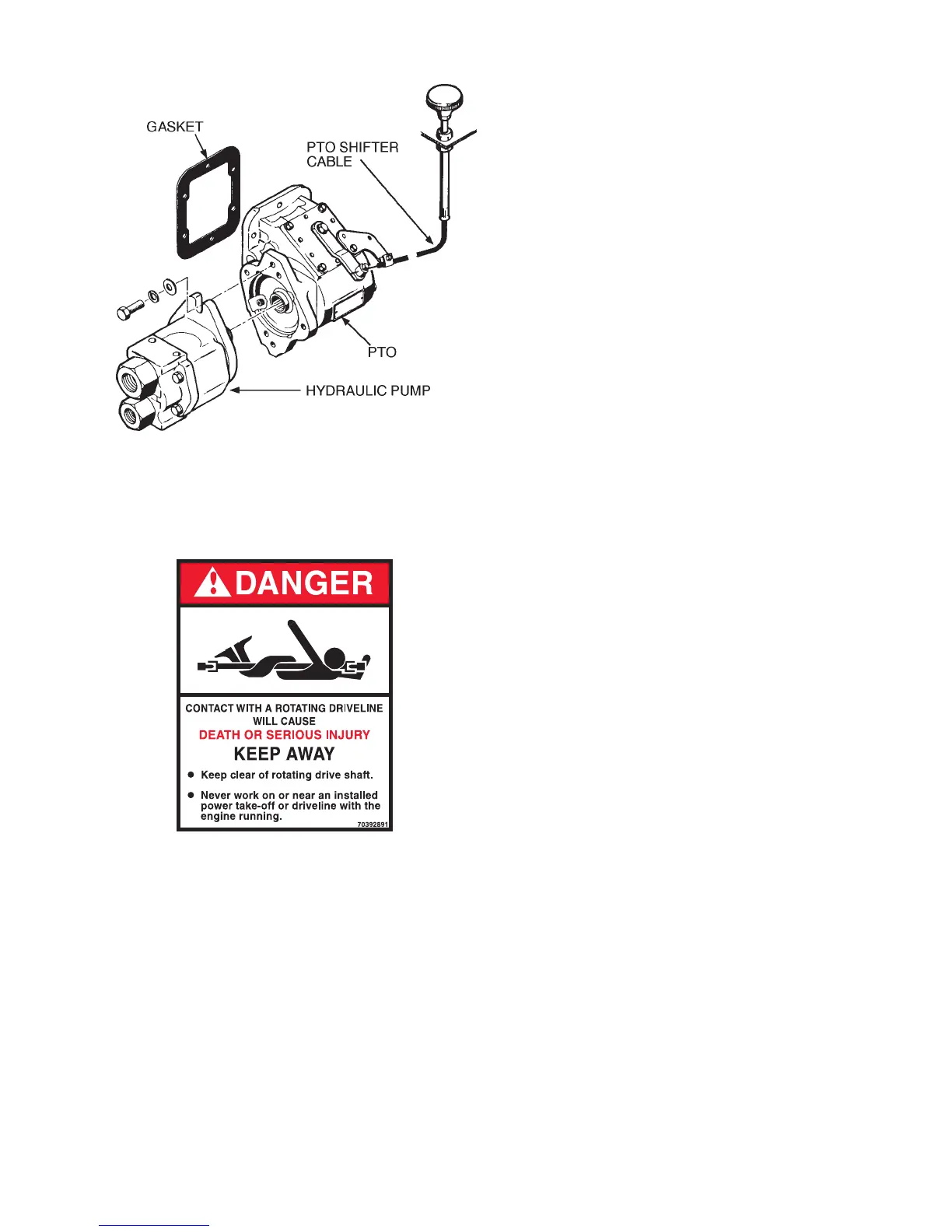

Figure D-3: PTO/Pump Installation

4-3-3: DRIVELINE APPLICATION

When you cannot directly mount the pump/

PTO is not feasible, you may use an auxiliary

driveshaft. To select the auxiliary driveshaft for

your installation, consider the following:

1. The driveshaft must be able to transmit

the necessary torque and RPM required.

Applications operating at less than 1200 RPM

may use a driveshaft constructed of solid bar

stock. More demanding applications will

require tubular shafts.

2. Avoid auxiliary driveshaft breakage and

personal injury by not exceeding the critical

speed of the selected driveshaft. Critical

speed is calculated using operating RPM,

shaft material and diameter, and installed

centerline to centerline length. Consult the

driveshaft manufacturer’s instructions for

specific information.

Normally, if calculations indicate a problem,

the use of multiple shafts and support bear-

ings is recommended.

3. The careful installation of a driveshaft with

concern for recommended driveline angles

will minimize vibration and provide trouble-free

operation.

4. The driveshaft must be capable of absorb-

ing any shock loads which may develop.

5. The driveshaft must be capable of varying

its length during installation and while trans-

mitting torque. This is refered to as “slip

movement”.

6. NEVER exceed the torque, length, angu-

larity and RPM limits specified by the manu-

facturer.

7. Only trained personnel using driveshaft

assembly equipment should fabricate a

driveshaft.

8. Balance tubular driveshafts.

20030115

Loading...

Loading...