Control Unit Installation Page 2.3 - 7 2.3

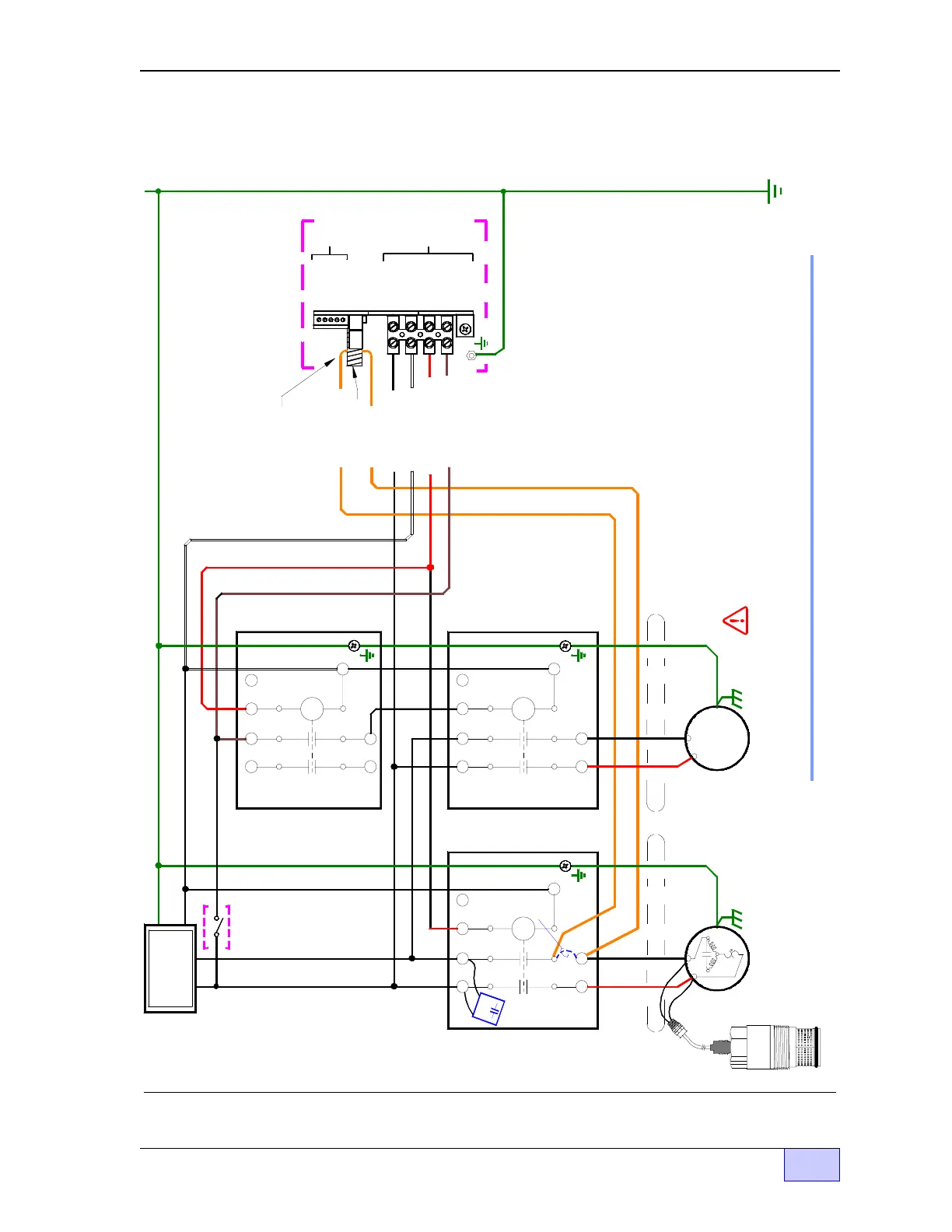

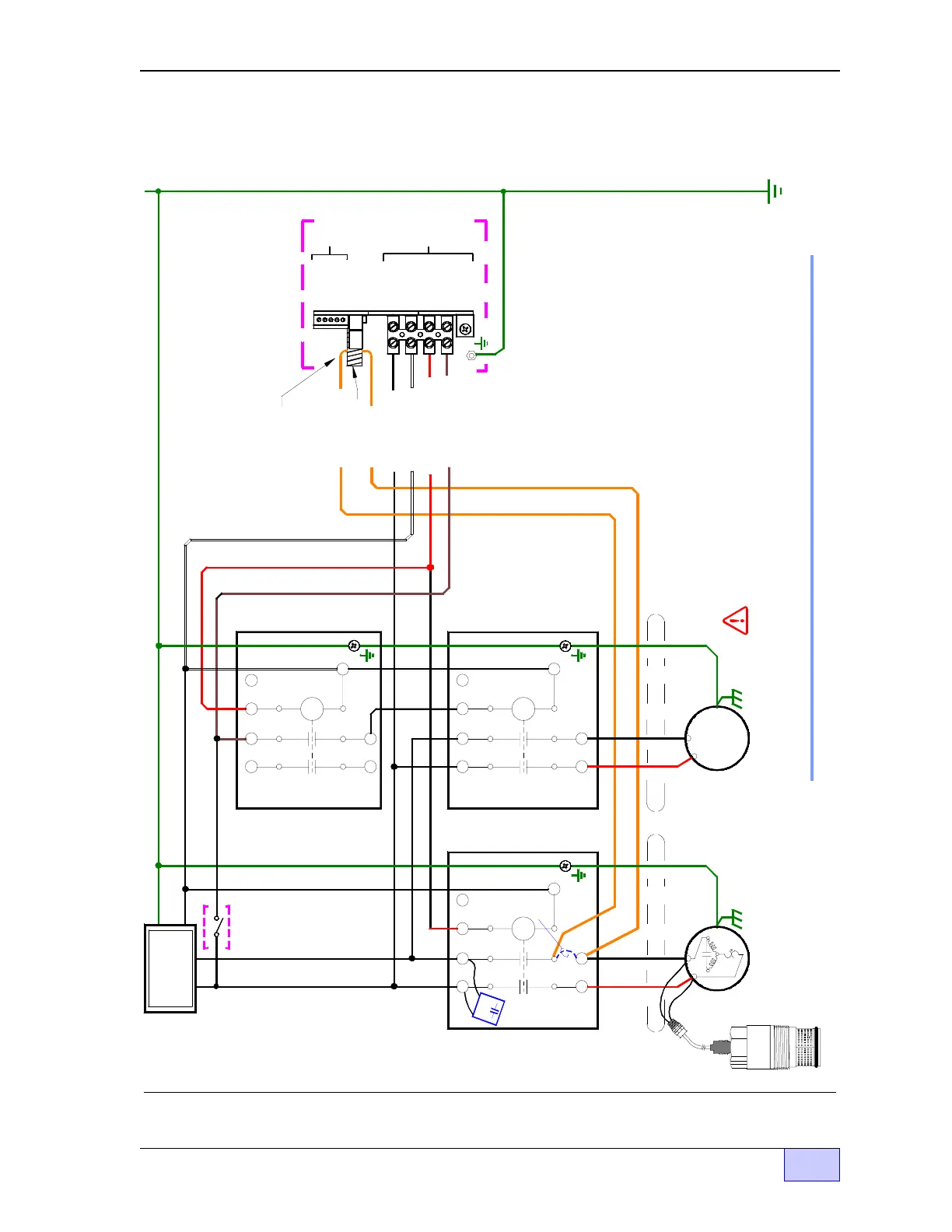

Figure 2.3-6 Single Phase 240 VAC Multiple Pump & Manifolded Line with Single LSU & CU

Interface Schematic

INCON TS-LLD - 1 LSU Multiple Pumps & Manifolded Lines - Wirin

Dia

ram

GND

GND

Pump Control

Relay Box # 1

(remove dashed wires)

P/N

020-0028

STP #1 Motor & LSU

TS-LLD LSU

at Leak Detection Port:

STP # 1 Pump Housing

OL

Install Line Filter

Cap at L1 and L2

N

M1 M2

Remove Wires

(dashed lines)

STP # 2 Motor

Conduit

to pump

Junction

Box

GND

M1

Pump Control

Relay Box # 2

M2

N

L1 L2 S1S2

Dispense

Switch(es)

Electrical

Power

Panel

L1 L2

N

GND

Aux. Relay Box

L1

M1

L2 S2 S1

M2

N

L1 L2 S2 S1

DANGER ELECTRICAL SHOCK HAZARDS. TURN OFF AND LOCK-OUT THE

SUBMERSIBLE PUMP POWER SOURCE AT THE CIRCUIT BREAKER - BEFORE -

WORKING ON THIS EQUIPMENT. FAILURE TO TURN OFF PUMP & DISPENSER

POWER SOURCE WILL RESULT IN SEVERE INJURY OR DEATH.

1) The Leak Sensing Unit (LSU) is installed at STP # 1

2) In line check valves are required at the output of

each RedJacket Submerged Turbine Pump

3) All ancillary pumps must be controlled / enabled

by the Aux. Relay Box as shown.

4) Only STP #1 Runs during line leak tests

NOTES

GND

No connection.

Wire is routed

through the

donut-shaped

Pickup Coil

Pickup Coil

TS-LLD Control Unit (CU)

Power Source = L1

Neutral (WHT)

RLY COIL (RED)

Dispense ( BRN)

Pump On Sig.

M1 (ORG)

L1 Line (BLK)

RLY N.O. (ORG)

1 485A

TB1

TB2

SIG RTN

4 P-IN

3 P-OUT

2 NEU

1 110V

5 ALARM

4 DSY2

F1

3 DSY1

2 485B

Loading...

Loading...