2.3 Page 2.3 - 14 TS-LLD INSTALLATION GUIDE

Shield

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

1 110V

2 NEU

3 P -OUT

TB1

4 P-IN

F1

UP

SIG RTN

TB2

INTERNAL VIEW

CU TOP VIEW

x x x x x x x

CU RIGHT SIDE VIEW

CU ENCLO SURE

TOP VIEW

KNOCKOUT

FOR 1/ 2 I NCH

ELECTRICAL

FITTING

AT TOP &

BOTTOM

Line # :

Product:

Use a

permanent

ink m arking

pen and

write the

Line #

Product:

on the

labe ls be low .

For Example

1

Gas

Line #:

Product:

1

G as

LLD # 1

Line # 1

Gasoline

Line #:

Product:

TS -LLD C U S erial N umber

x x x x x x x x

CU Serial

Num ber

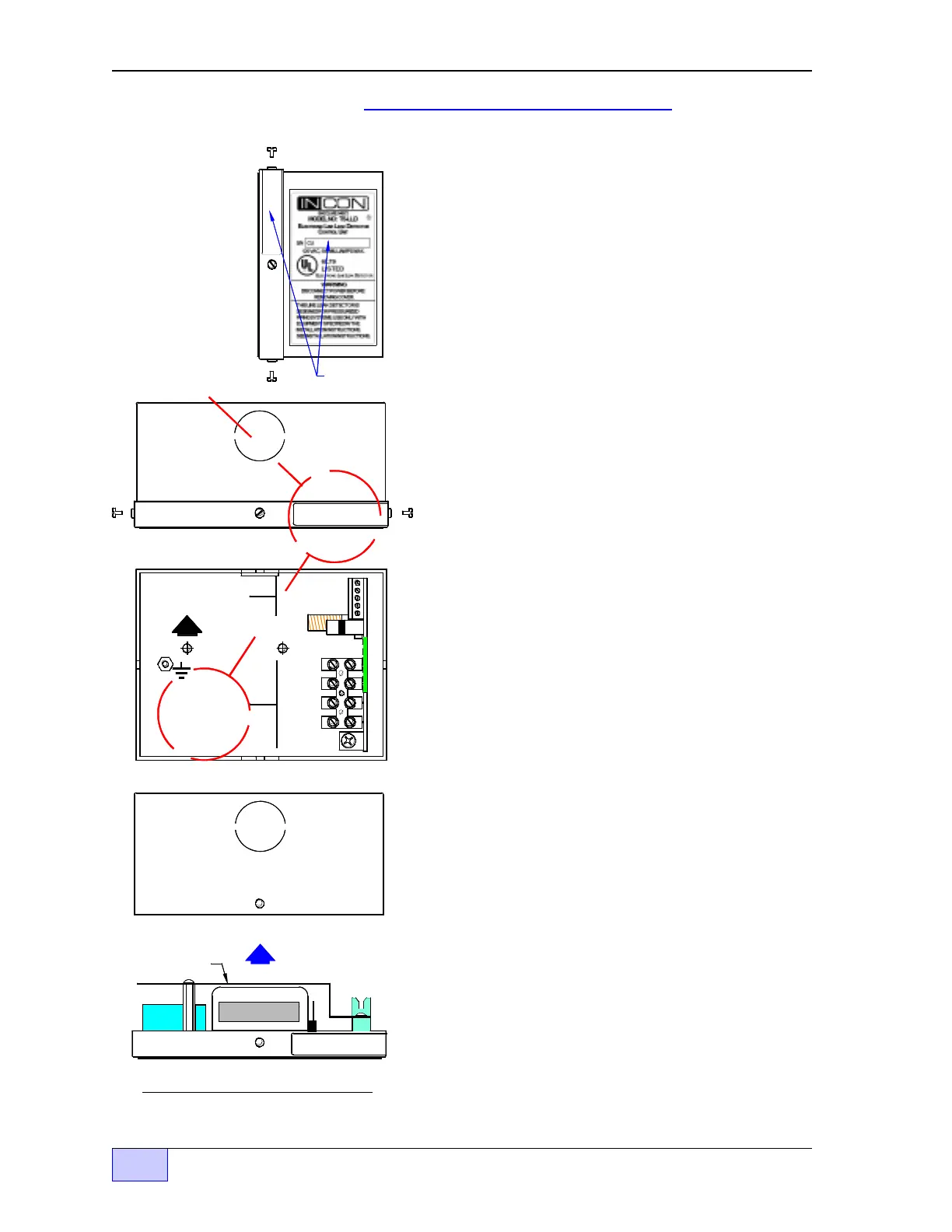

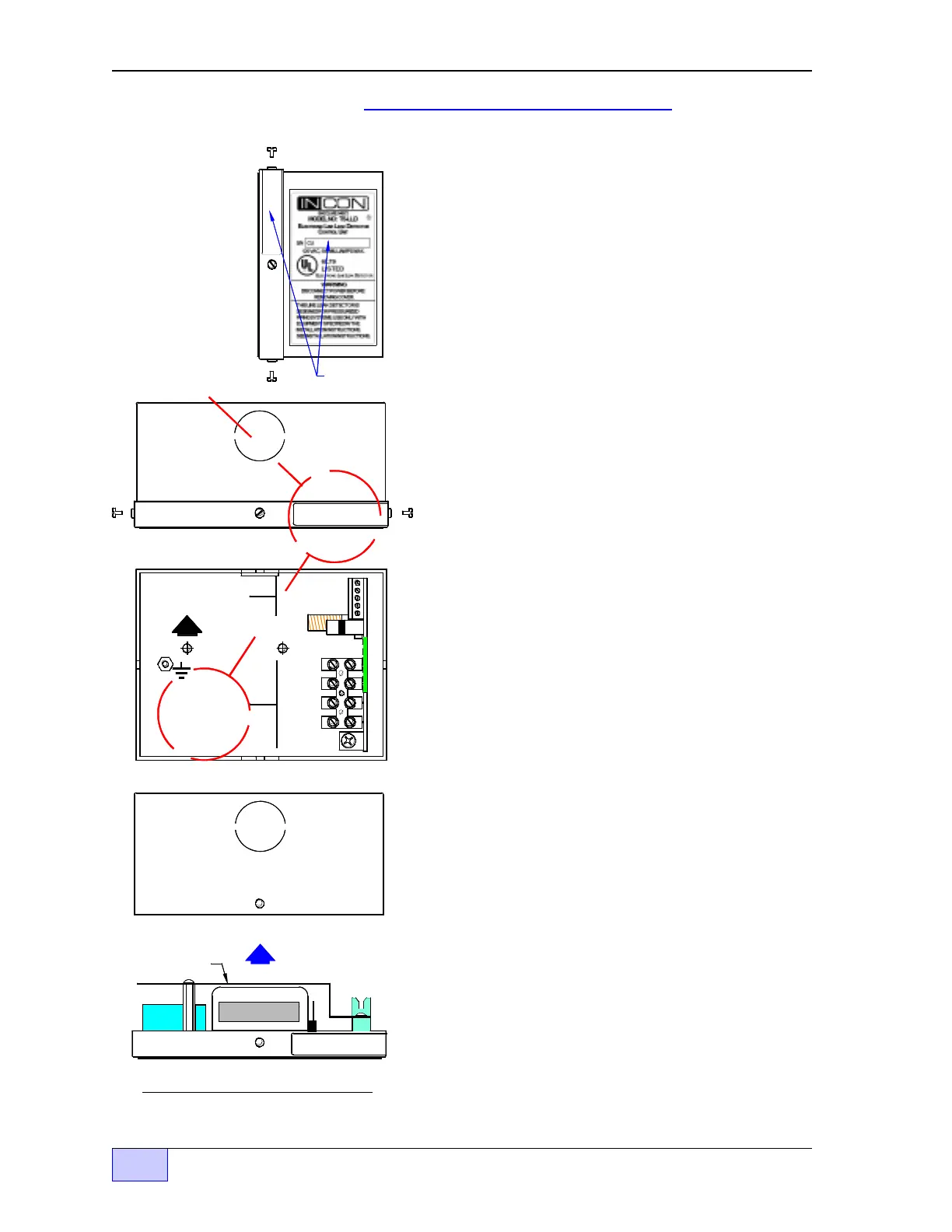

Figure 2.3-13 Control Unit

Final Assembly

Final Installation Steps

6) Recheck your wiring. Make sure all terminations

are correct and tight.

7) Use a permanent ink marking pen to: write the

Line # and the Product being monitored on two

CU labels — The label inside of the control unit,

and the label located on the top right of the cover

label (so the box and cover can be reinstalled as a

matched-set). See Figure 2.3-6 to the left.

8) Reinstall the correct CU cover on the box – as

a matched-set. See Figure 2.3-6 to the left.

9) Reinstall the pump relay box cover. See

Figures 2.3-1 & 2.3-3.

10) Nine INCON Danger stickers are supplied with

each line leak detector (P/N 240-1175). Apply

one sticker: on the pump relay box cover, in

locations near dispenser fuel-line filters, plugs,

emergency safety-shut-off valves, on the TS-LLD

Leak Sensing Unit, and onto other serviceable

components of a fuel line (where a spill would

occur if the line became pressurized). The

selected surfaces must be clean, dry, and in plain

sight so that the warning can be read and followed.

Finally, see the next few Sections of this Chapter

about Optional Tank Gauge Console Interface and

the After Installation Steps / Testing.

—

❖

—

Loading...

Loading...