6 Troubleshooting

- 59 -

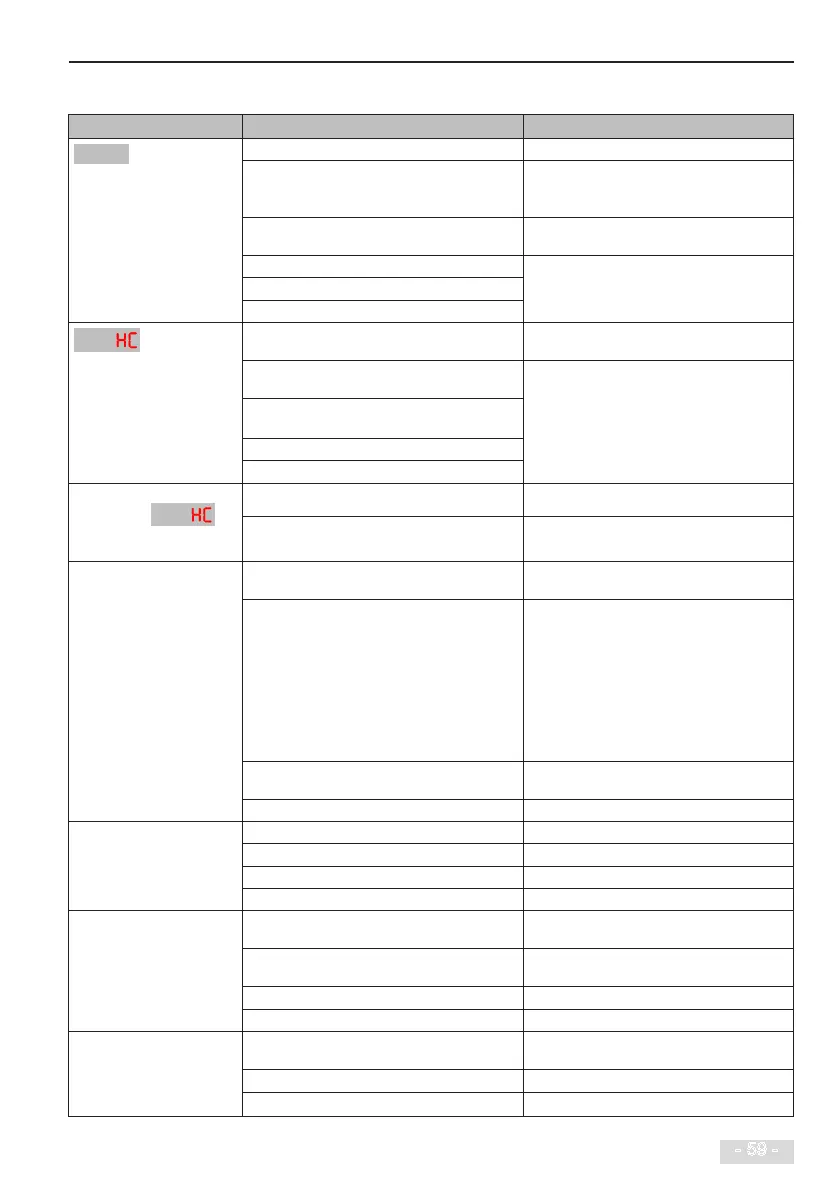

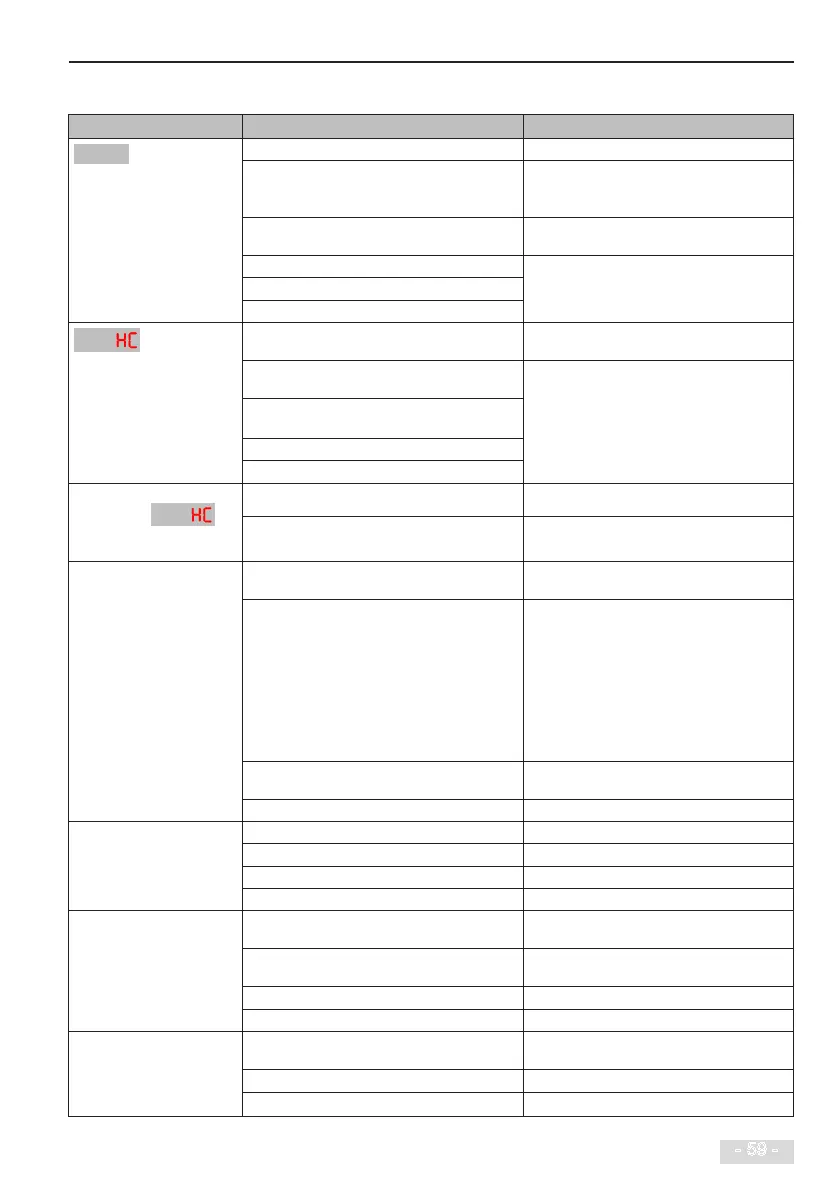

6�2 Servo Common Symptoms and Diagnostics

Fault Name Possible Causes Solutions

There is no display at power-

on�

The Mains voltage is not input or too low� Check the power supply�

The switching power supply on drive board of the

servo drive is faulty�

Check bus voltage�

Check that the 24v output and +10v output on

the control board are normal�

Wires between control board and drive board and

between control board and operating panel break�

Re-connect the 8-pin wire and 40-pin wire�

Pre-charge resistor of the servo drive is damaged� Contact Inovance�

Control board or operating panel is faulty�

Rectier bridge is damaged.

is displayed at

power-on�

Wire between drive board and control board is in

poor contact�

Re-connect the 8-pin wire and 28-pin wire�

Related components on control board are

damaged

Contact Inovance�

The motor or motor cable is short circuited to

ground�

The hall is damaged�

The Mains voltage is too low�

The display is normal upon

power-on, but is

displayed after start and the

motor stops immediately�

The cooling fan is damaged or locked-rotor occurs� Replace the fan�

Short circuit exists in wiring of control terminals� Eliminate short circuit fault in control circuit

wiring�

The motor does not rotate

after the servo drive runs�

It is motor or motor cable problem� Check that wiring between servo drive and motor

is normal�

Related servo drive and motor parameters are set

improperly�

Restore the factory parameters and re-set the

following parameters properly:

•

Encoder parameters

•

Motor ratings, such as rate motor frequency

and rated motor speed

•

Motor 1 control mode (F0-01) and command

source selection (F0-02)

•

F3-01 (torque boost) in V/F control under

heavy-load start�

Cable connection between drive board and control

board is in poor contact�

Re-connect wirings and ensure secure

connection�

The drive board is faulty� Contact Inovance�

The DI terminals are Disabled� Related parameters are set incorrectly� Check and set parameters in group f4 again�

External signals are incorrect� Re-connect external signal cables�

Jumper across op and +24 v becomes loose� Re-conrm the jumper bar across op and +24 v.

The control board is faulty� Contact Inovance�

Motor speed Does not rise in

FVC control�

Encoder is faulty� Replace encoder and re-conrm cable

connection�

Encoder connection is incorrect or in poor contact� Reconnect the encoder to ensure in good

contact�

PG card is faulty� Replace the PG card�

Drive board is faulty� Contact Inovance�

The servo drive detects

overcurrent and overvoltage

frequently�

Motor parameters are set improperly� Set motor parameters or perform motor auto-

tuning again�

Acceleration/deceleration time is improper� Set proper acceleration/deceleration time�

Load uctuates. Contact Inovance�

Loading...

Loading...