Operation, Display and Application Examples

MD380 User Manual

- 56 -

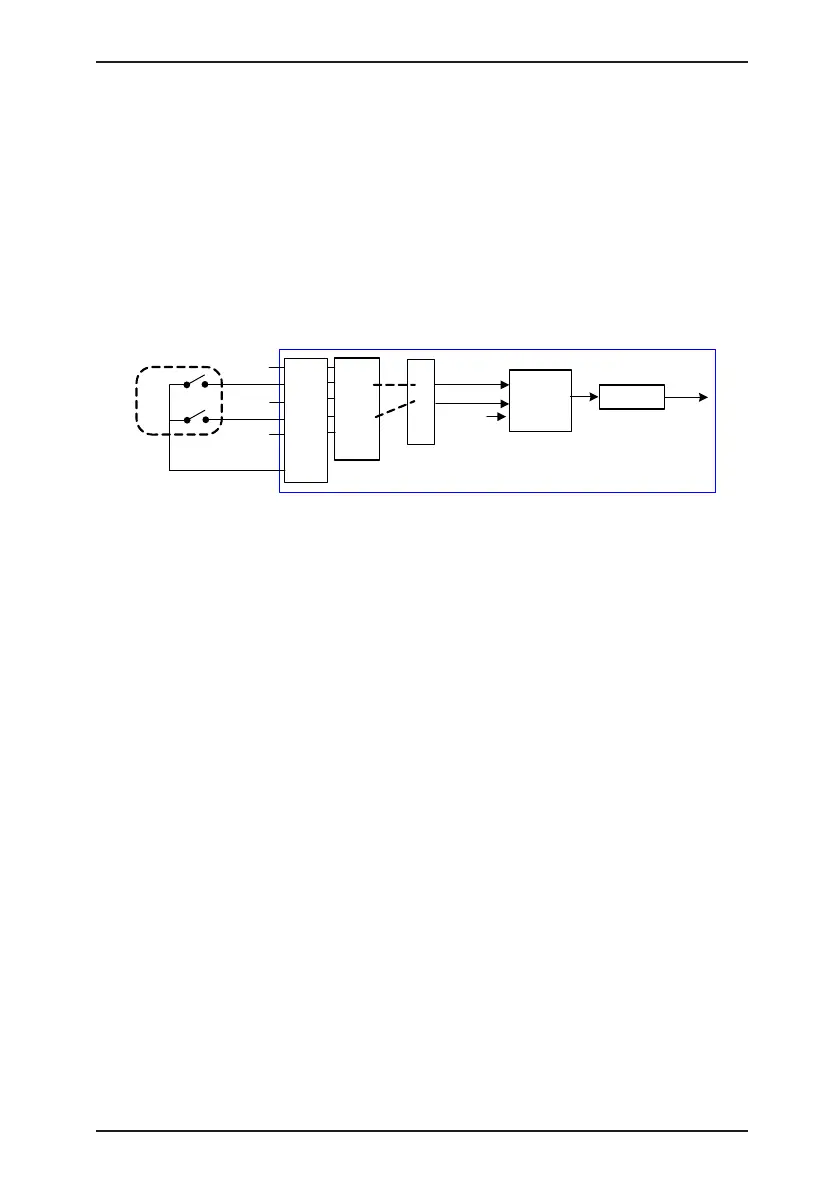

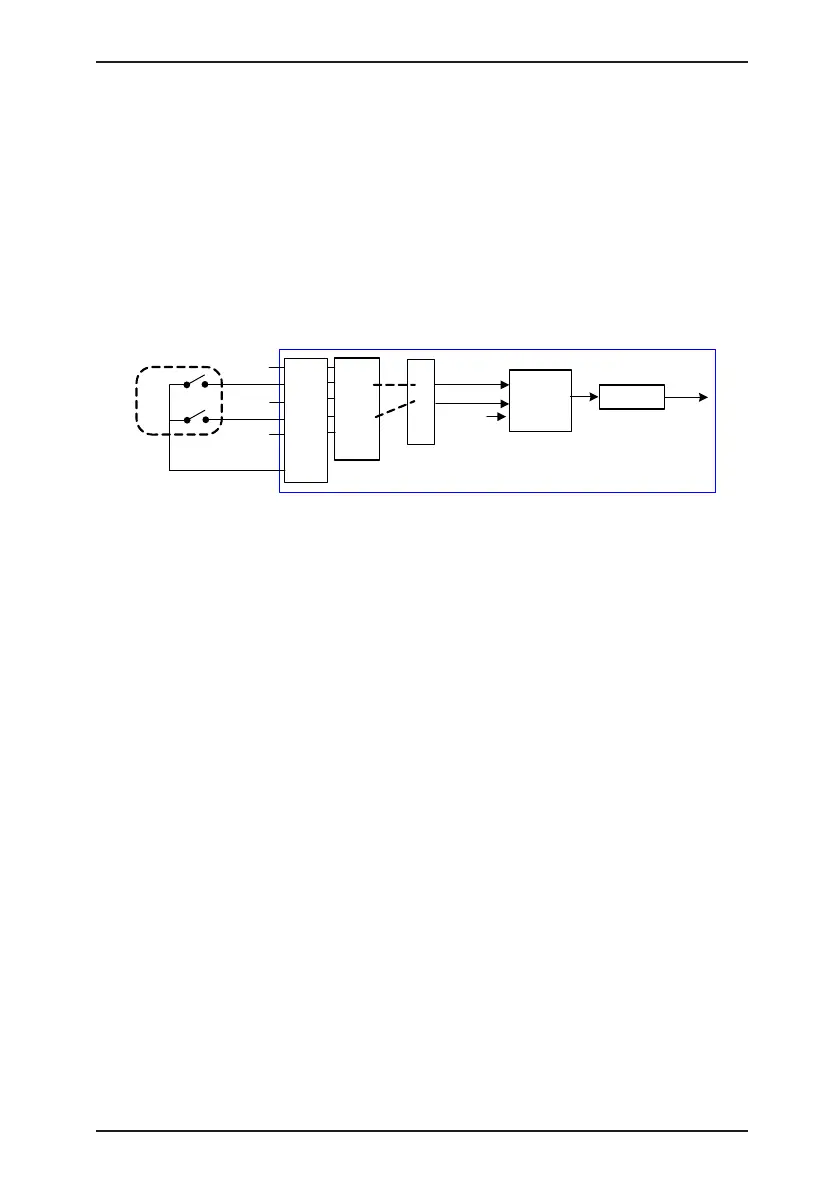

• 2: Communication control

The most common conguration is when the host computer is used to control running

of the AC drive by means of communication, such as the RS485, PROFIBUS-DP,

CANlink, and CANopen. The MD380 interacts with the user programmable card also by

means of communication.

Install a matching communication card in the multifunction extension port, and set F0-

02 to 2. Then, you can start or stop the AC drive in communication mode. The following

gure shows the setting method.

Figure 4-8 Setting for start/stop using the communication control mode

F4-00

F4-01

F4-02

F4-03

F4-04

.

.

1

2

.

.

F0-02 = 1

Running

command

F4-11 = 0

Control switch

Terminal

Function

code

Setting

value

Terminal

control

DI1

DI2

DI3

DI4

DI5

.

COM

RUN/

Forward

Forward RUN

Terminal control

Command source

selection

Two-line mode 1

RUN/

Reverse

Reverse RUN

SW2

SW1

When FD-04 is set to a non-zero number, the function of automatic AC drive stop upon

communication timeout is enabled. This prevents uncontrollable AC drive running due

to faults of the communication cable or the host computer.

The communication port of the AC drive supports the Modbus-RTU protocol, and the

communication is implemented only when the host computer supports the Modbus-

RTU master station protocol.

4.7.2 Start Mode

The MD380 supports three start modes, namely, direct start, rotational speed tracking

restart, and pre-excited start (asynchronous motor), set in F6-00.

• F6-00 = 0 (direct start)

It is applicable to small-inertia load. The frequency curve in this mode is shown in the

following gure.

DC braking before the start is applicable to drive of load such as elevator and crane.

Startup frequency is applicable to drive with burst start under start torque, such as

cement mixer.

Loading...

Loading...