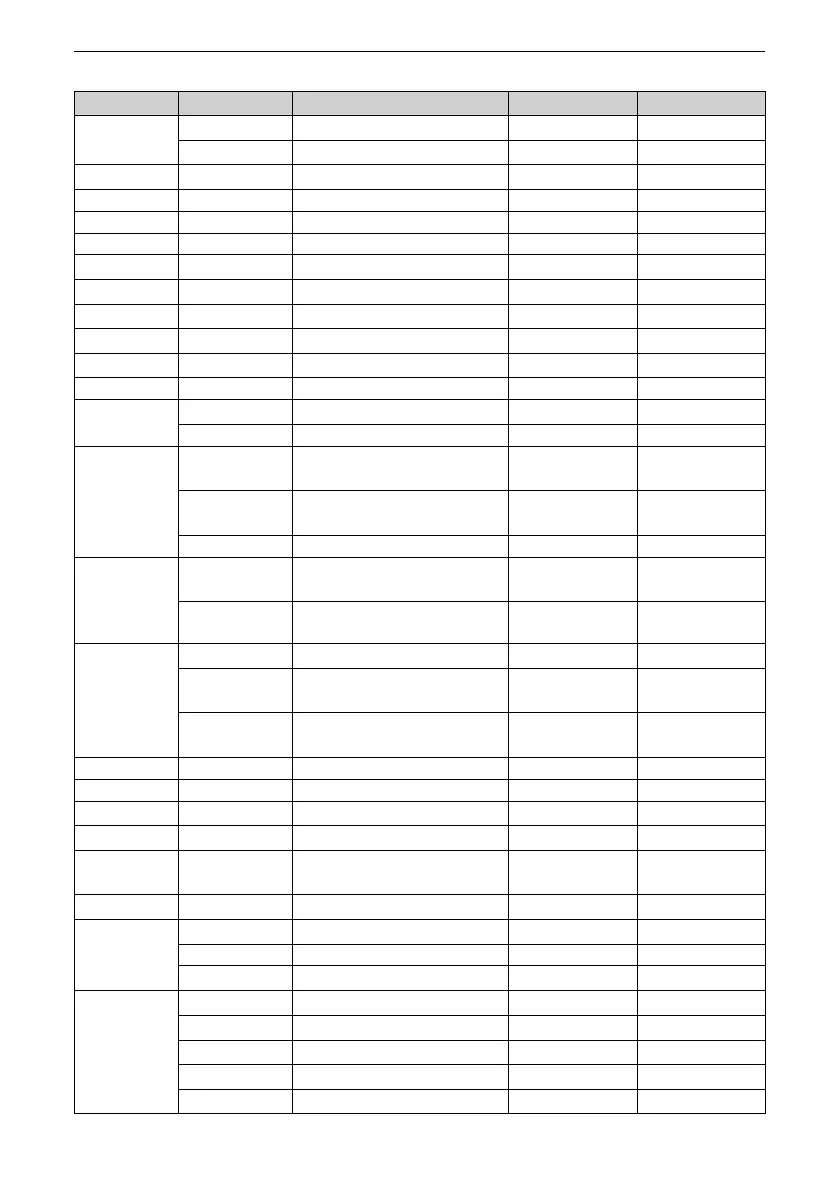

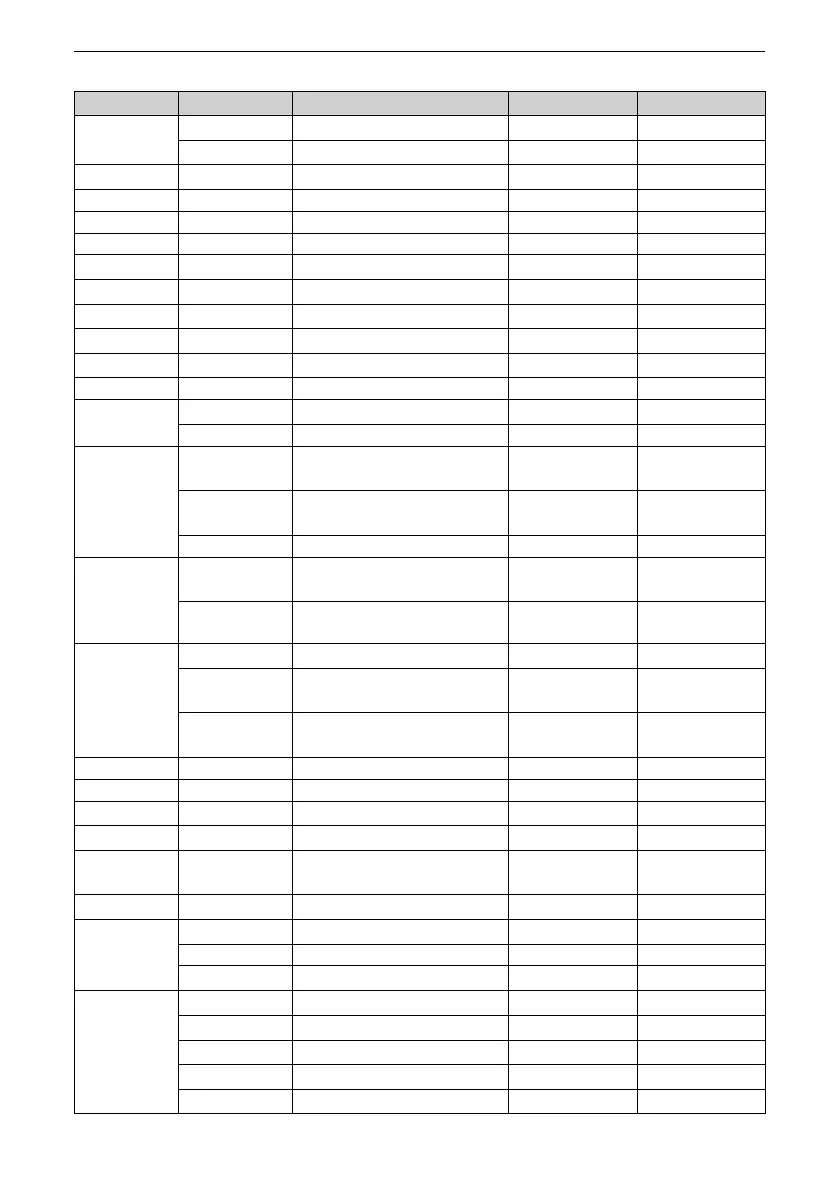

List of Fault Codes

‑101‑

Fault Code

Display

Fault Name

Fault Type

Resettable

E420

E420.0

Main circuit phase loss

No. 2 Yes

E420.1

Main circuit PL signal detection error

No. 2 Yes

E430 E430.0

Control power supply undervoltage

No. 2 Yes

E661 E661.0 STune failure No. 2 Yes

E662 E662.0 ETune failure No. 2 Yes

E663 E663.0 ITune failure No. 2 Yes

E664 E664.0

Excessive system resonance

No. 2 Yes

E731 E731.0

Encoder battery failure

No. 2 Yes

E733 E733.0

Encoder multi‑turn counting error

No. 2 Yes

E735 E735.0

Encoder multi‑turn counting overflow

No. 2 Yes

E760 E760.0

Encoder over‑temperature

No. 2 Yes

E994 E994.0 Station number conflict No. 2 Yes

EB00

EB00.0

Position deviation too large

No. 2 Yes

EB00.1 Position deviation overflow No. 2 Yes

EB01

EB01.0

The position reference increment is

too large.

No. 2 Yes

EB01.1

Individual position reference

increment too large

No. 2 Yes

EB01.3 Reference overflow No. 2 Yes

EB02

EB02.0

Position deviation too large in fully

closed‑loop mode

No. 2 Yes

EB02.1

Fully closed‑loop position deviation

overflow

No. 2 Yes

EB03

EB03.0

Electronic gear ratio overrun

No. 2 Yes

EB03.1

Electronic gear ratio beyond the limit

‑ Electronic gear ratio 1

No. 2 Yes

EB03.2

Electronic gear ratio beyond the limit

‑Electronic gear ratio 2

No. 2 Yes

ED02 ED02.0 Modbus communication timeout No. 2 Yes

ED03 ED03.0 CANLink communication failure No. 2 Yes

ED04 ED04.0

CANopen communication timeout

No. 2 Yes

ED05 ED05.0

CANopen communication initialized

No. 2 Yes

ED08 ED08.0

CANopen bus PDO transmission

length error

No. 2 Yes

ED11 ED11.0

CANopen sync period error too large

No. 2 Yes

EE08

EE08.0

Synchronization loss

No. 2 Yes

EE08.1 Network status switchover error No. 2 Yes

EE08.3

Link is missing

No. 2 Yes

EE09

EE09.0

Software position limit setting error

No. 2 Yes

EE09.1

Home setting error

No. 2 Yes

EE09.2

Gear ratio beyond the limit

No. 2 Yes

EE09.3

No synchronization signal

No. 2 Yes

EE09.5

PDO mapping beyond the limit

No. 2 Yes

Loading...

Loading...