Chapter: Maintenance

40 M10-14052-EN

Troubleshooting

Improper adjustments or a lack of maintenance is the cause of most grip operating

problems. To help you when a problem develops, Table 5 suggests a probable cause

and recommends a solution.

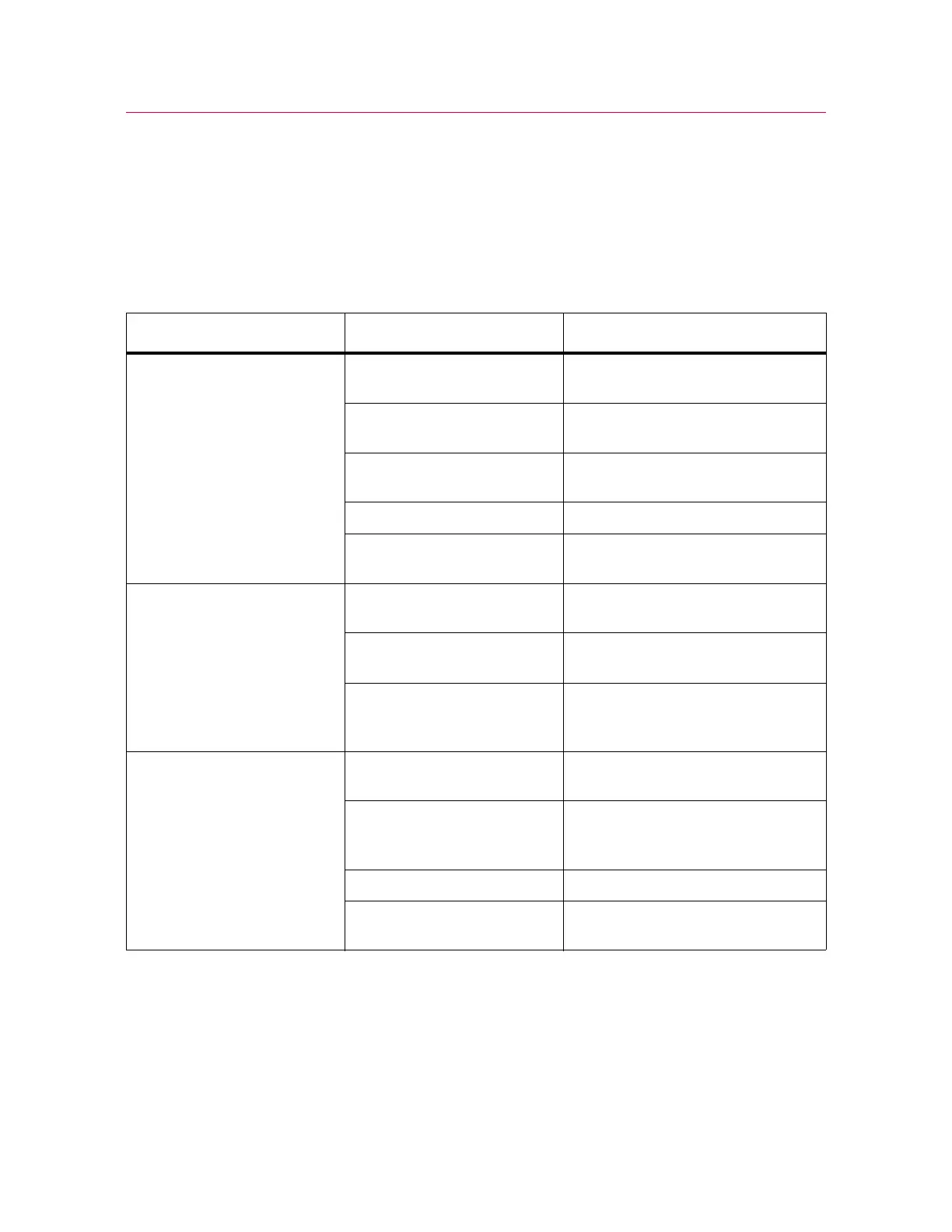

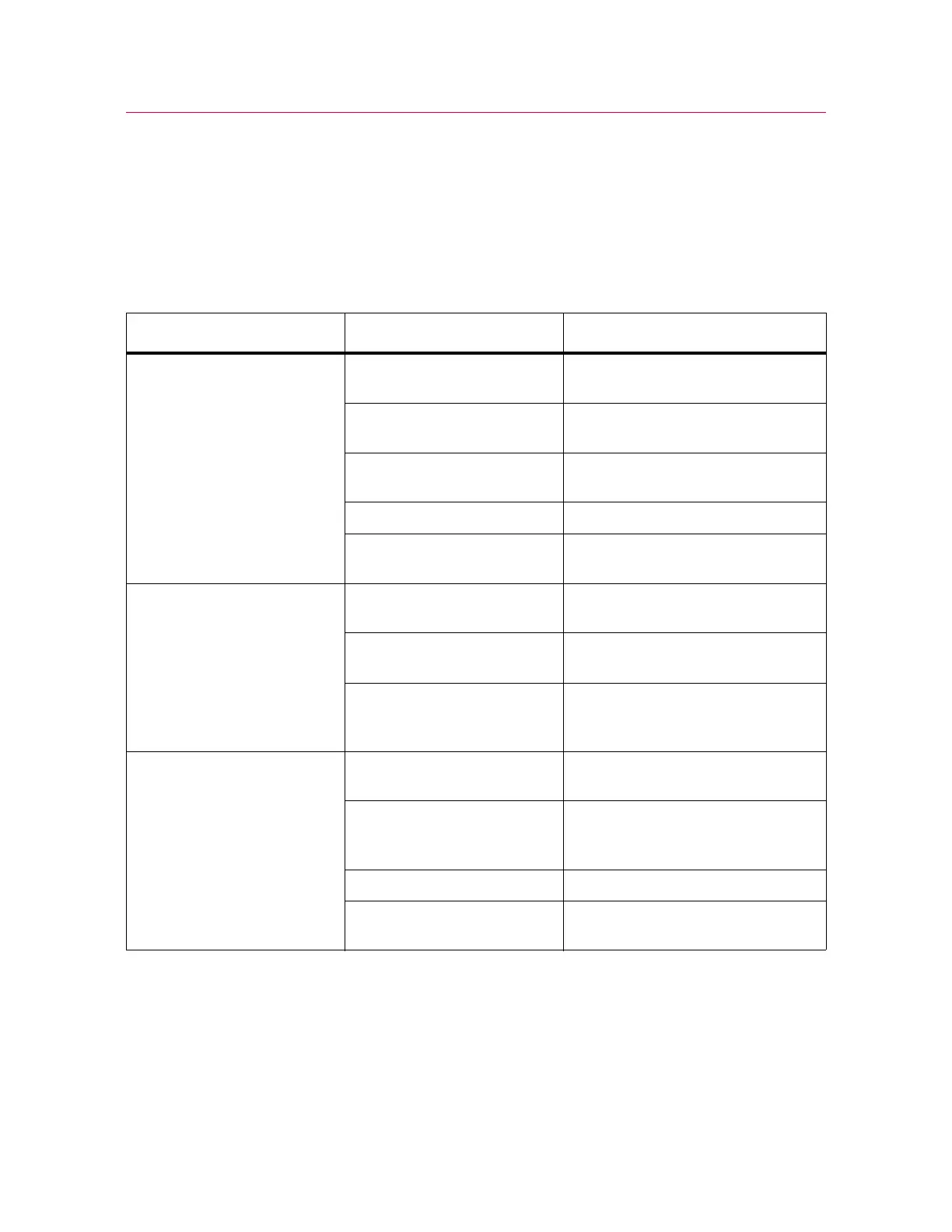

Table 5. Troubleshooting

Problem Cause Remedy

Specimen slips while under

load

Wrong size or type of jaw face Install appropriate jaw face for

specimen size and type

Cyclic or compressive loads Do not use wedge action grip for

cyclic or compressive testing

Not enough gripping area Install specimen for complete

engagement with jaw faces

Not enough preload Tighten the grip handles

Not enough lubricant on jaw

faces

Lubricate the back of the jaw faces

Specimen breaks at jaw face Initial gripping force is too

great for specimen

Do not over-tighten control nut

Misalignment of a load string

component

Verify alignment of load frame and

specimen

Dirt, corrosion, specimen

debris or other contaminants

are obstructing face clearance

Remove jaw faces, clean the head

tapers, apply Molykote g-N paste and

install jaw faces

Jaw faces will not release or

do not completely retract

Jaw face serrations are bound

to specimen

Lightly tap specimen to release bond

Dirt, corrosion, specimen

debris or other contaminants

are obstructing face clearance

Remove jaw faces, clean the head

tapers, apply Molykote g-N paste and

install jaw faces

Tensile load on specimen Remove tensile load

Not enough lubricant on jaw

faces

Lubricate the back of the jaw faces

Loading...

Loading...