CAUTION

When an additive is added to the CH water, ensure it is

suitable for the materials used in the appliance, such as

copper, brass, stainless steel, steel, plastic and rubber.

1. Connect to 3 amp fused spur, or via a three pin plug to an unswitched socket.

2. Connect the appliance to mains.

The appliance may perform a self test: 2 (on service display).

The appliance will then go into wait mode: - (on service display).

14. Connect the filling loop and fill the installation with clean drinking water to a

maximum pressure of 1-2 bar in the case of a cold installation. (Indicated on the

temperature display.)

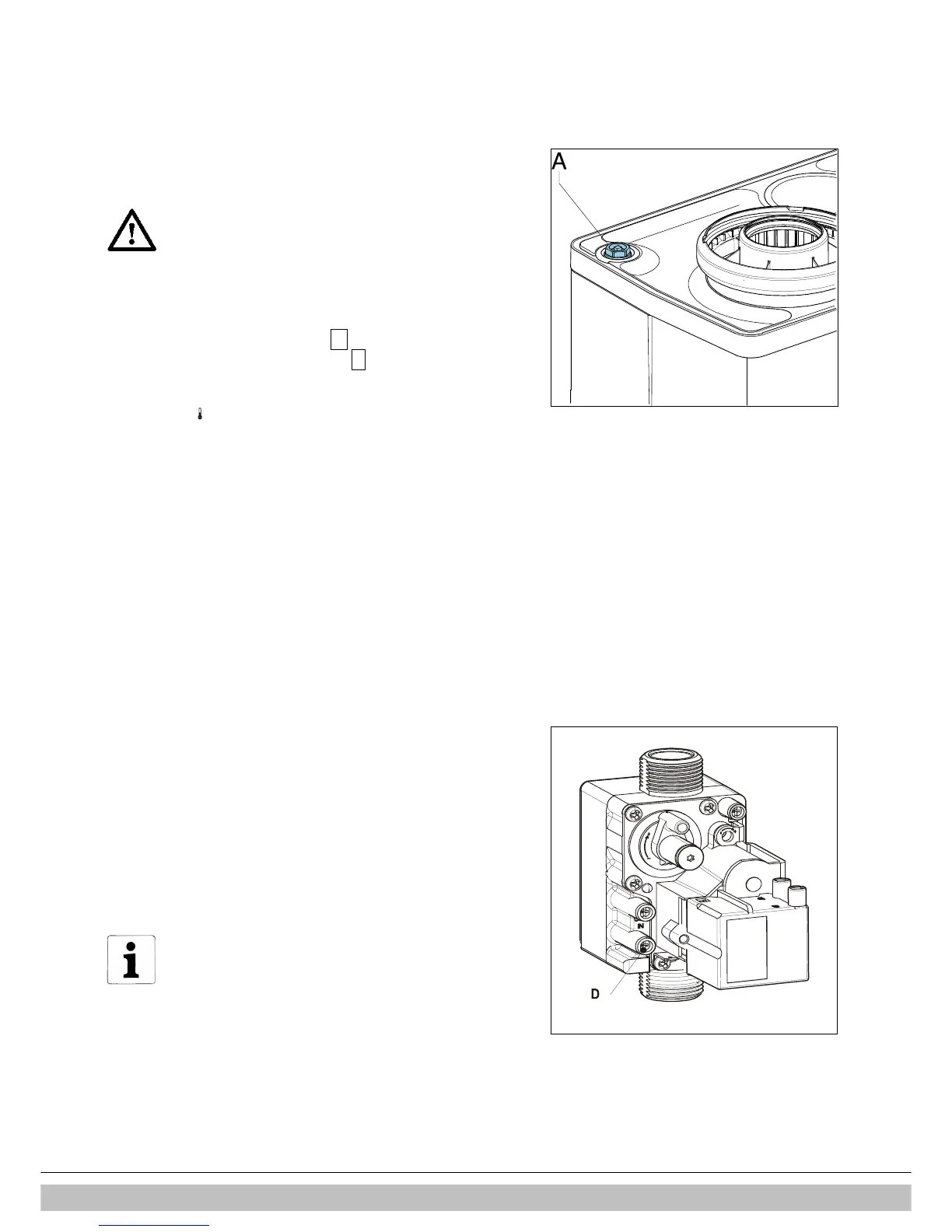

15. Bleed the appliance with the manual bleed screw (A).

An automatic air bleeding device may be fitted to the appliance in place of the

manual bleed screw.

16. Bleed the air in the installation with the manual bleed screws on the radiators.

17. Top up the CH installation if the pressure has dropped too far as a result of the

air bleeding.

18. Check all couplings for leakage.

19. Fill the condensate trap with water.

9.1.2 Hot water supply (only when an indirectly heated DHW storage

cylinder is applied)

1. Open the main tap to pressurise the hot water section.

2. Vent the exchanger and the pipe system by opening a hot water tap.

3. Leave the tap open until all air has disappeared from the system.

4. Check all connections for leaks including internal connections.

9.1.3 Gas supply

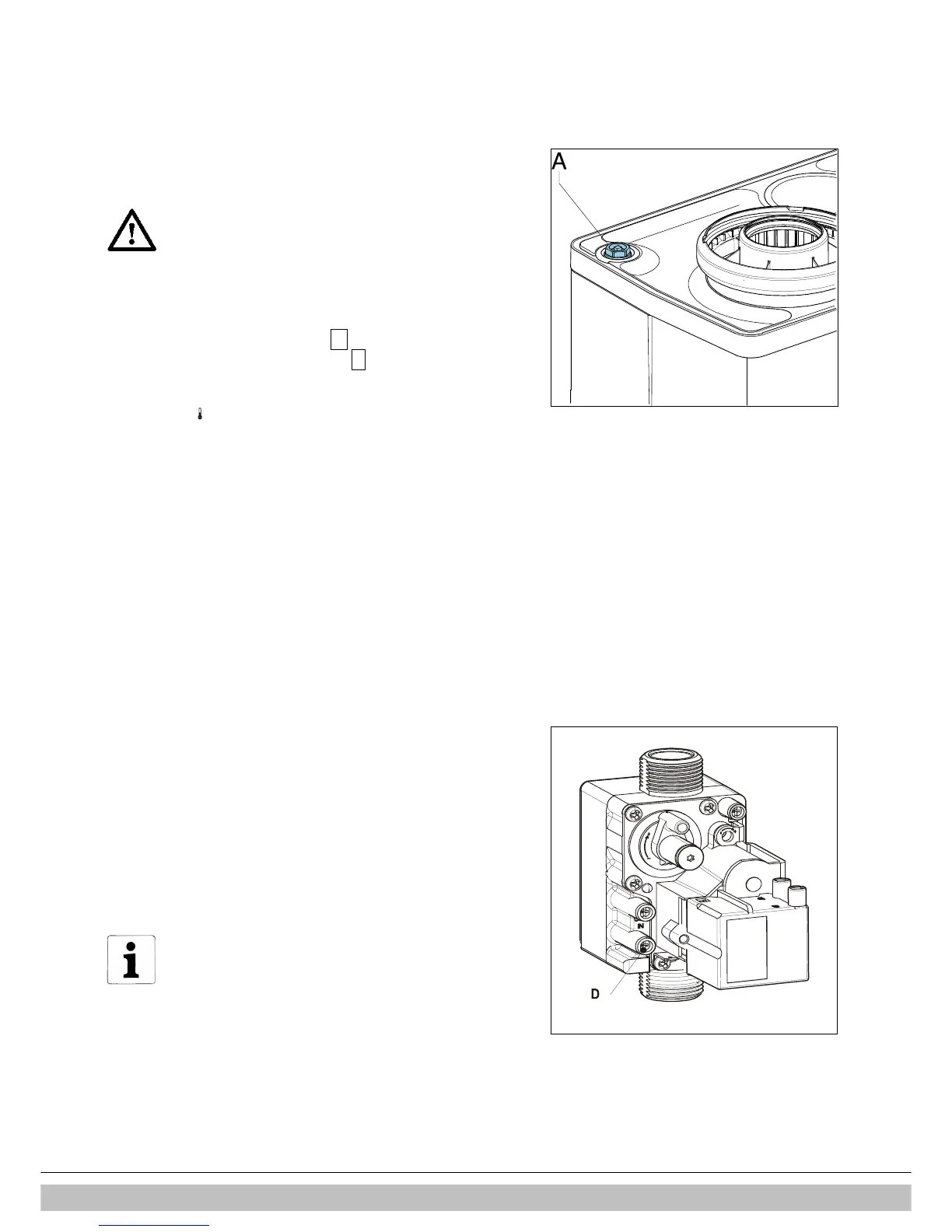

1. Gas supply purged of air via test point D on gas valve (see illustration )

2. Connect a suitable gauge to test point D .

Static or standing pressure must be 20mb. If 20mb is not obtained

DO NOT proceed with commissioning until supply is rectified.

3. If static pressure is correct fire the boiler and allow to reach working

temperature.

4. Test working pressure by selecting test program “H”. See section 10.8, High

Setting. Working pressure must be 20mb +or- 1mb.

If working pressure is less than 19mb appliance heat output will be reduced and

correct combustion readings may not be obtained. Do not adjust the air/gas

ratio. Correct gas supply to obtain sufficient working pressure.

Loading...

Loading...