71

Matrix Mono

Part 3 - Installaon and Field Sengs

Matrix Mono

70

Inventor Matrix Mono Engineering Data Book

Uninhibited glycol will turn acidic under the influence of oxygen. This process is accelerated by presence of copper and at

higher temperatures. The acidic uninhibited glycol attacks metal surfaces and forms galvanic corrosion cells that cause

severe damage to the system. It is of extreme importance:

That the water treatment is correctly executed by a qualified water specialist.

That a glycol with corrosion inhibitors is selected to counteract acids formed by the oxidation of glycols.

That in case of an installation with a domestic hot water tank, only the use of propylene glycol is allowed. In other

installations the use of ethylene glycol is fine.

That no automotive glycol is used because their corrosion inhibitors have a limited lifetime and contain silicates that

can foul or plug the system;

That galvanized piping is not used in glycol systems since it may lead to the precipitation of certain elements in the

glycol’s corrosion inhibitor;

To ensure that the glycol is compatible with the materials used in the system.

3.5 Water Flow Switch

Water may enter into the flow switch and cannot be drained out and may

freeze when the temperature is low enough. The flow switch should be

removed and dried, then can be reinstalled in the unit.

Counterclockwise rotation, remove the water flow switch.

Drying the water flow switch completely.

3.6 Adding Water

Connect the water supply to the fill valve and open the valve.

Make sure the automatic air purge valve is open (at least 2 turns).

Refer to Figure 3-3.3.

Fill with water until the manometer indicates a pressure of

approximately 2.0 bars. Remove air in the circuit as much as possible

using the air purge valve. Air in the water circuit could lead to

malfunction of the backup electric heater.

3.7 Water Piping Insulation

The complete water circuit including all piping, water piping must be insulated to prevent condensation during cooling

operation and reduction of the heating and cooling capacity as well as prevention of freezing of the outside water piping

during winter. The insulation material should at least of B1 fire resistance rating and complies with all applicable legislation.

The thickness of the sealing materials must be at least 13mm with thermal conductivity 0.039W/mK in order to prevent

freezing on the outside water piping. If the outdoor ambient temperature is higher than 30°C and the humidity is higher

than RH 80%, the thickness of the sealing materials should be at least 20mm in order to avoid condensation on the surface

of the seal.

Figure 3-3.2: Water flow switch

Figure 3-3.3: Air purge valve

Do not fasten the black plastic

cover on the vent valve at the

topside of the unit when the

system is running. Open air

purgevalve,turn anticlockWise

at least2 full turnsto releaseair

from the system.

Matrix Mono

71

Part 3 - Installation and Field Settings

4 Electrical Wiring

4.1 General

4.2 Precautions

Fix cables so that cables do not make contact with the pipes (especially on the high pressure side).

Secure the electrical wiring with cable ties as shown in Figure 3-1.14 and Figure 3-1.15. So that it does not come in

contact with the piping, particularly on the high-pressure side.

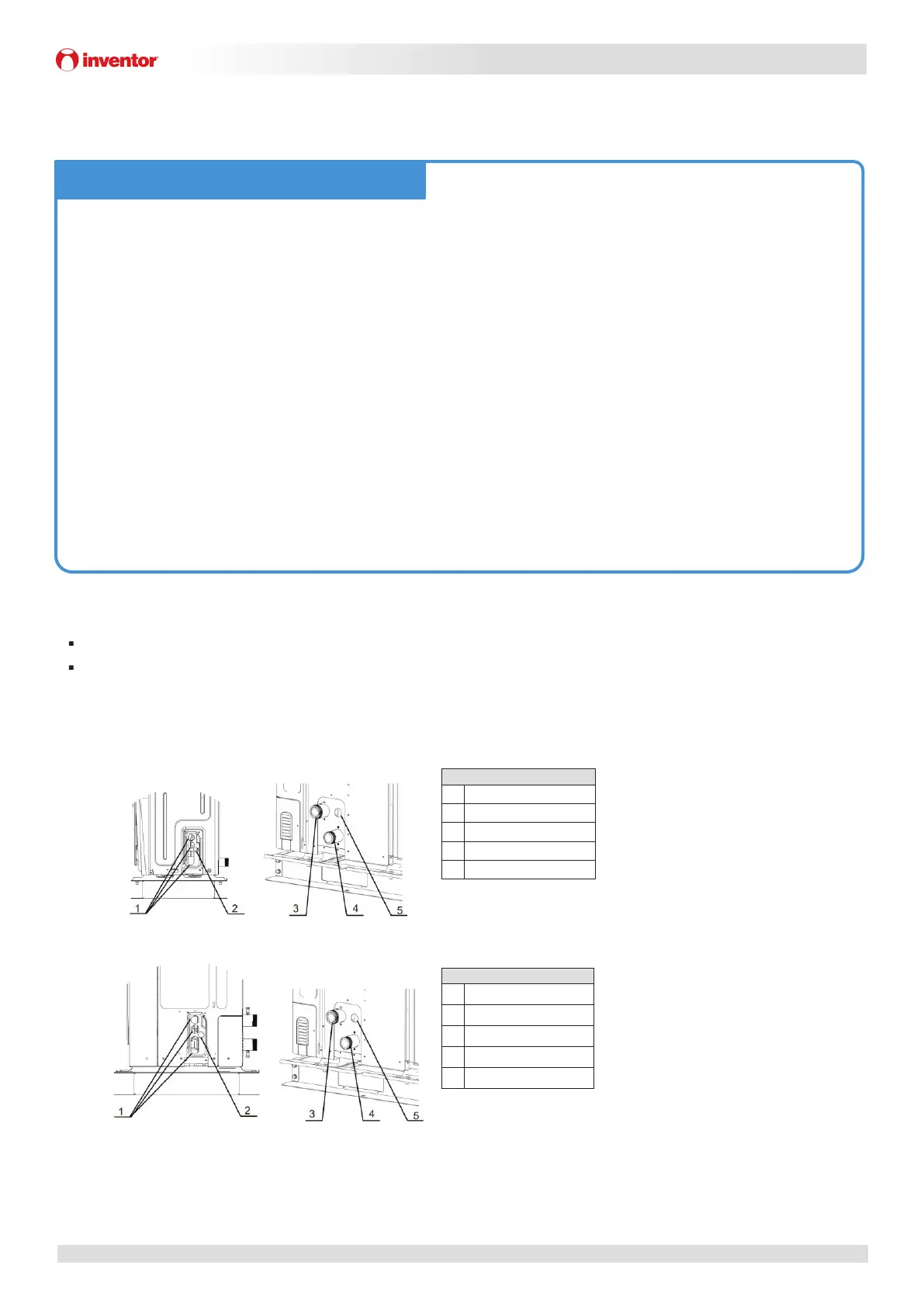

Figure 3-4.1: Wiring hole for 4/6kW models

1 High voltage wire hole

4 Water inlet

5 Water outlet

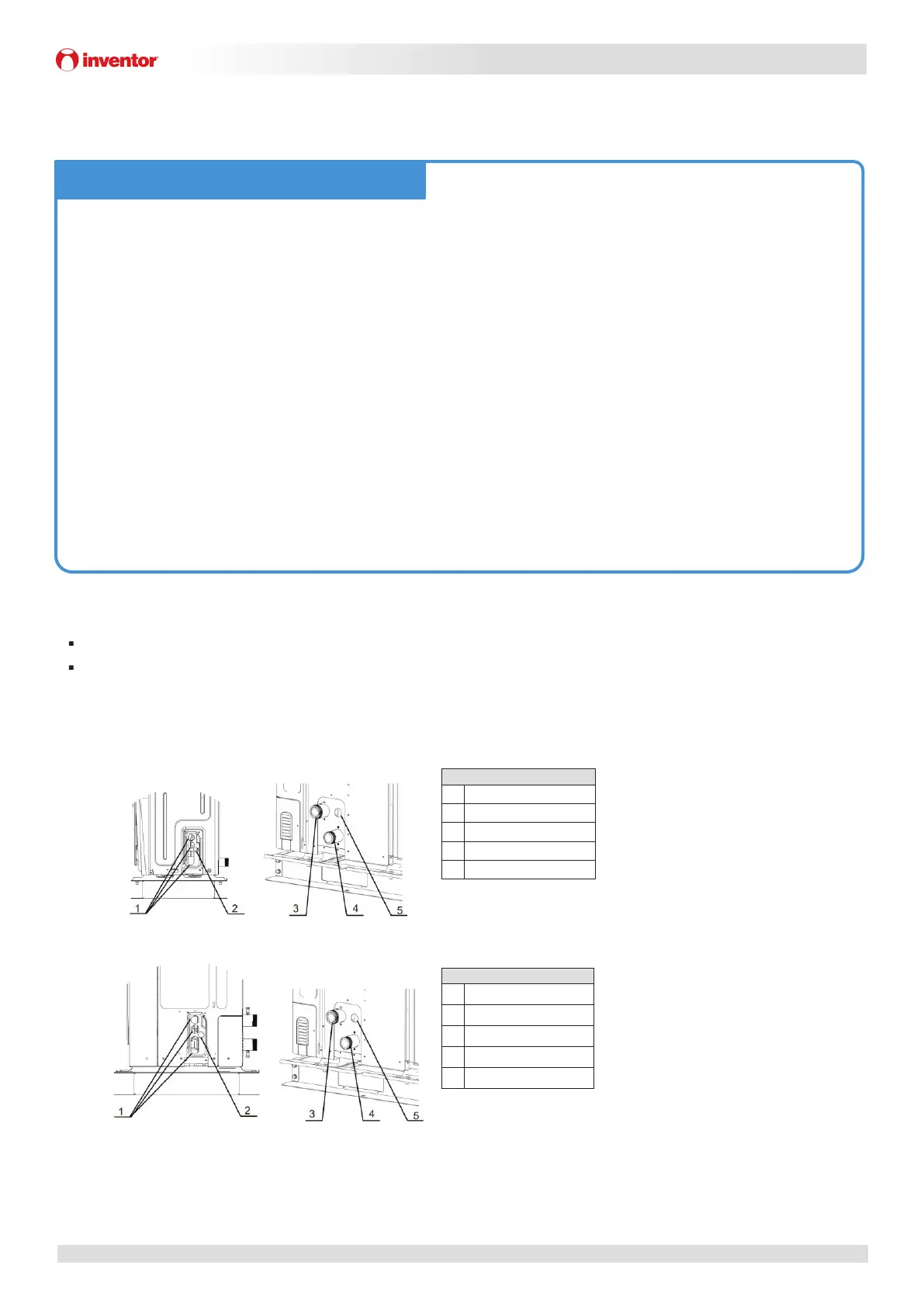

Figure 3-4.2: Wiring hole for 8~16kW models

1 High voltage wire hole

2 Low voltage wire hole

3 Drainage pipe hole

4 Water outlet

5 Water inlet

Caution

All installation and wiring must be carried out by competent and suitably qualified, certified and accredited

professionals and in accordance with all applicable legislation.

Electrical systems should be grounded in accordance with all applicable legislation.

Overcurrent circuit breakers and residual-current circuit breakers (ground fault circuit interrupters) should be

used in accordance with all applicable legislation.

Wiring patterns shown in this data book are general connection guides only and are not intended for, or to

include all details for, any specific installation.

The water piping, power wiring and communication wiring are typically run in parallel. However the

communication wiring should not be bound together with power wiring. To prevent signal interference, the

power wiring and communication wiring should not be run in the same conduit. If the power supply is less than

10A, a separation of at least 300mm between power wiring and communication wiring conduits should be

maintained; if the power supply is in the range 10A to 50A then a separation of at least 500mm should be

maintained.

Notes for installers

Loading...

Loading...