Goodrive300 Series VFD Peripherial options and parts

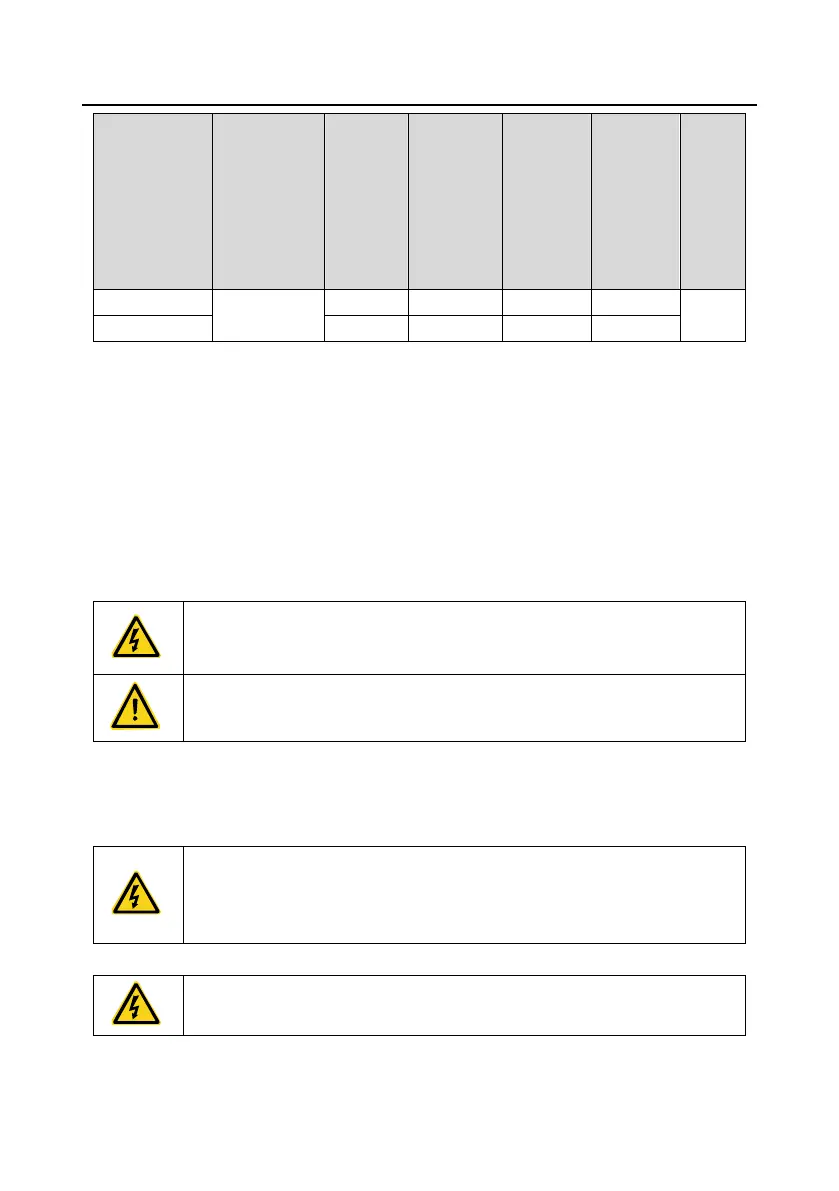

281

Brake

resistor

value

matched

with 100%

brake

torque (Ω)

Dissipation

power of

brake

resistor (kW)

(10% brake)

Dissipated

power of

brake

resistor

(kW)

(50%

brake)

Dissipated

power of

brake

resistor

(kW)

(80%

brake)

Min

allowed

brake

resistor

(Ω)

Note:

1. Select brake resistors according to the resistance and power data provided by our company.

2. The brake resistor may increase the brake torque of the VFD. The preceding table describes the

resistance and power for 100% brake torque, 10% brake usage, 50% brake usage, and 80% brake

usage. You can select the brake system based on the actual operation conditions.

3. When using an external brake unit, set the brake voltage class of the brake unit properly by

referring to the manual of the dynamic brake unit. If the voltage class is set incorrectly, the VFD may

not run properly.

• Never use a brake resistor with a resistance below the minimum value

specified for the particular drive. The drive and the internal chopper are not

able to handle the overcurrent caused by the low resistance.

• Increase the power of the braking resistor properly in the frequent braking

situation (the frequency usage ratio is more than 10%).

D.8.2 Selecting the brake resistor cables

Brake resistor cables need to be shielded cables.

D.8.3 Placing the brake resistor

All resistors need to be installed in places with good cooling conditions.

• The materials near the brake resistor or brake unit must be non-flammable.

The surface temperature of the resistor is high. Air flowing from the resistor is

of hundreds of degrees Celsius. Prevent any materials from coming into

contact with the resistor.

Installation of the braking resistor:

• The VFDs of 380V (≤30kW) only need external braking resistors.

• PB and (+) are the wiring terminals of the braking resistors.

Loading...

Loading...